Sound insulation gasket for car body cavity

A technology of sound insulation and sealing, car body, applied in vehicle parts, transportation and packaging, etc., can solve the problems of expansion glue 5 falling off and forming, small contact area, expansion glue falling off and forming, etc., to achieve increased contact area, blocking and blocking Good effect, prevent bad molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

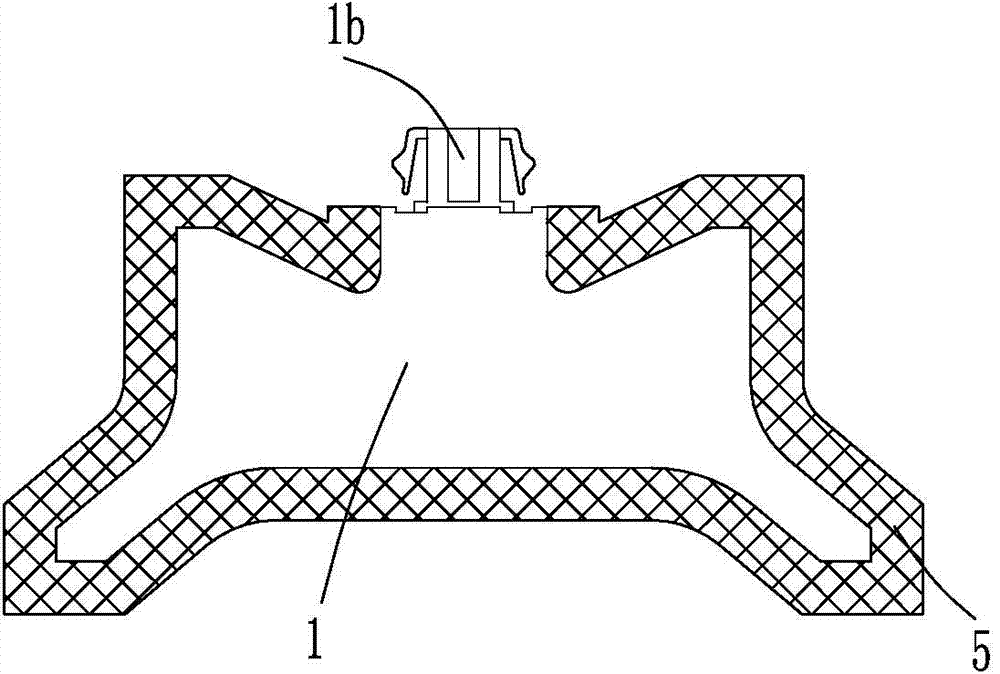

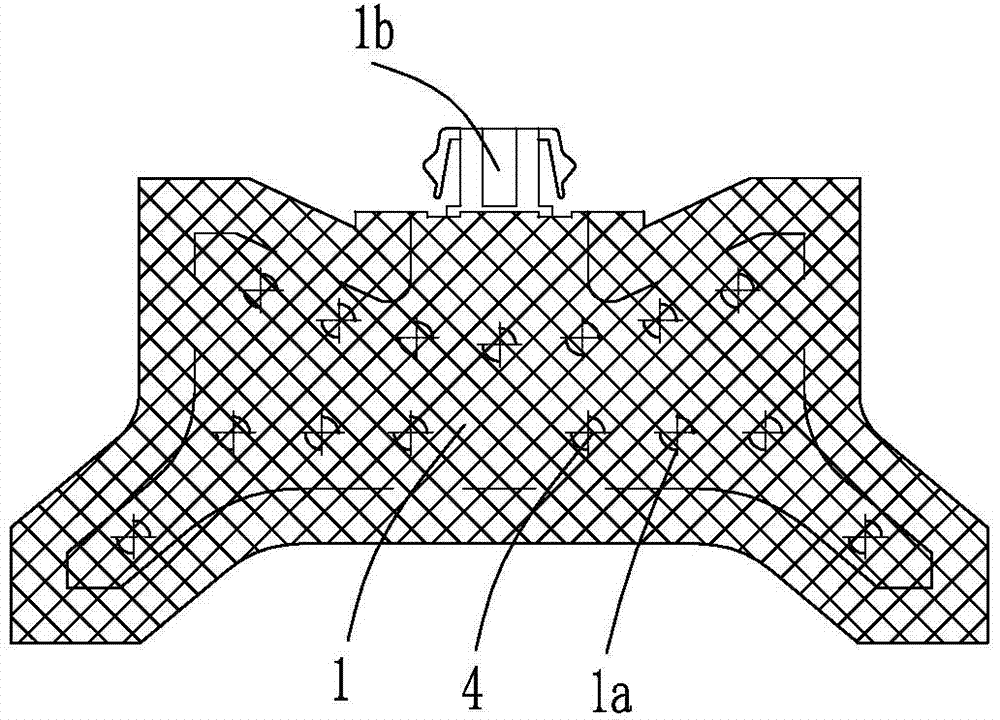

[0014] combine image 3 with 4 As shown, a car body cavity soundproof gasket is composed of a supporting frame 1 and expansion glue. The support frame 1 includes a front plane, a rear plane and circumferential side walls. A first expansion glue 2 with the same thickness is adhered on the circumferential side wall of the supporting frame 1, and the supporting frame 1 is usually a high temperature resistant nylon material. The above description is consistent with the structure of the existing body cavity soundproof gasket.

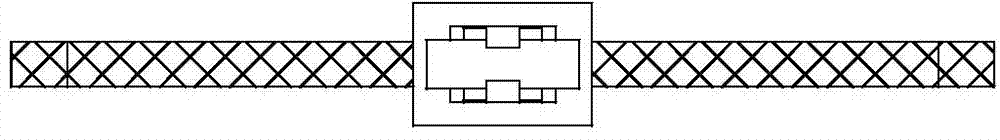

[0015] The difference is that the second expansion glue 3 with the same thickness is adhered to the front and rear planes of the support frame 1, and the support frame 1 is provided with a communication hole 1a that runs through the front and rear planes, and the communication hole 1a is filled with the third expansion glue. 4; the periphery of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com