Full-automatic mesh bag packing machine for fruit packing operations

A fully automatic, packaging machine technology, applied in packaging, packaging food, transportation and packaging, etc., can solve the problems of unsightly appearance, low production efficiency, irregular packaging, etc., and achieve the effect of high efficiency, convenient operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

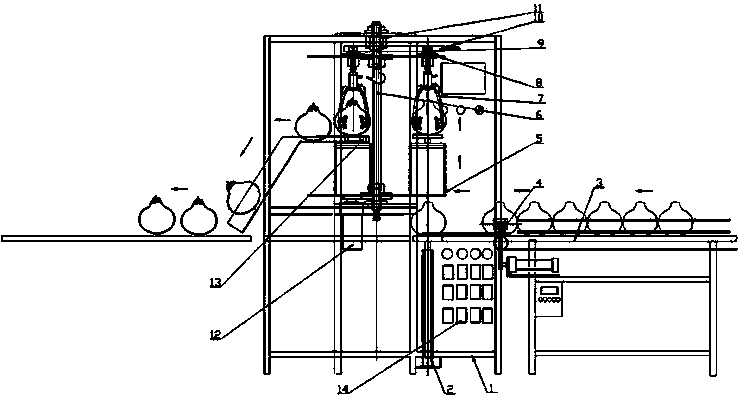

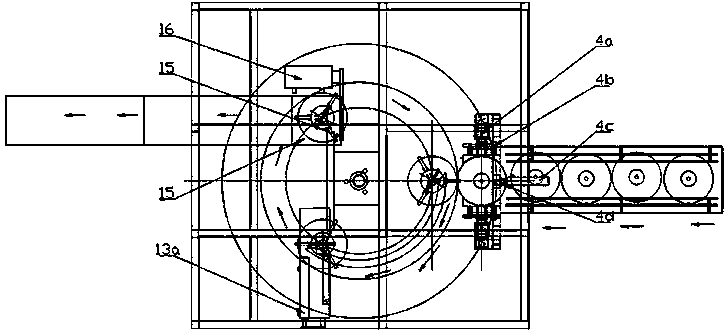

[0013] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: a fully automatic net bag packaging machine for fruit packaging operations, including a frame 1, an ascending cylinder 2, a belt conveyor 3, a flat delivery device 4, a net cylinder 5, and a rotating main shaft 6 , three-jaw fixture 7, turntable 8, bumper 9, bumper spring return device 10, anti-winding wire wheel 11, servo motor 12, double-row binding machine 13 and control box 14, and one side of frame 1 is provided with a belt conveyor Machine 3, the belt conveyor 3 is provided with a flat delivery device 4, the bottom of the belt conveyor 3 is provided with a rising cylinder 2, the side of the rising cylinder 2 is provided with a control box 14, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com