Automobile paste high-expansion vibration-reduction and sound-insulation rubber and manufacturing process thereof

A production process and high-expansion technology, which is applied in the field of automobile paste-like high-expansion vibration-damping and sound-insulating adhesives, can solve the problems of poor flame retardancy of materials, inconvenient automatic production and automatic construction, and complicated processes, so as to meet performance requirements and facilitate automatic production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

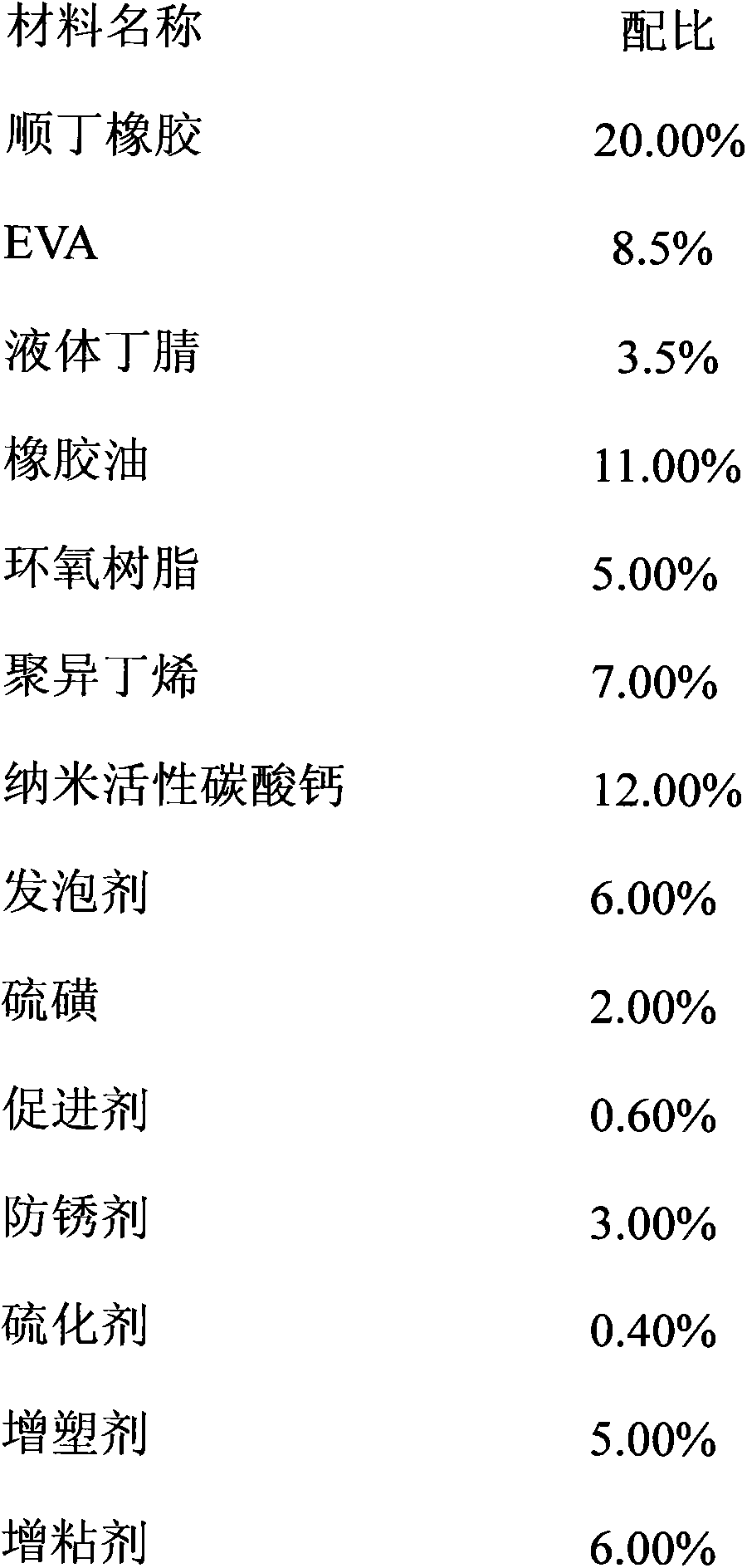

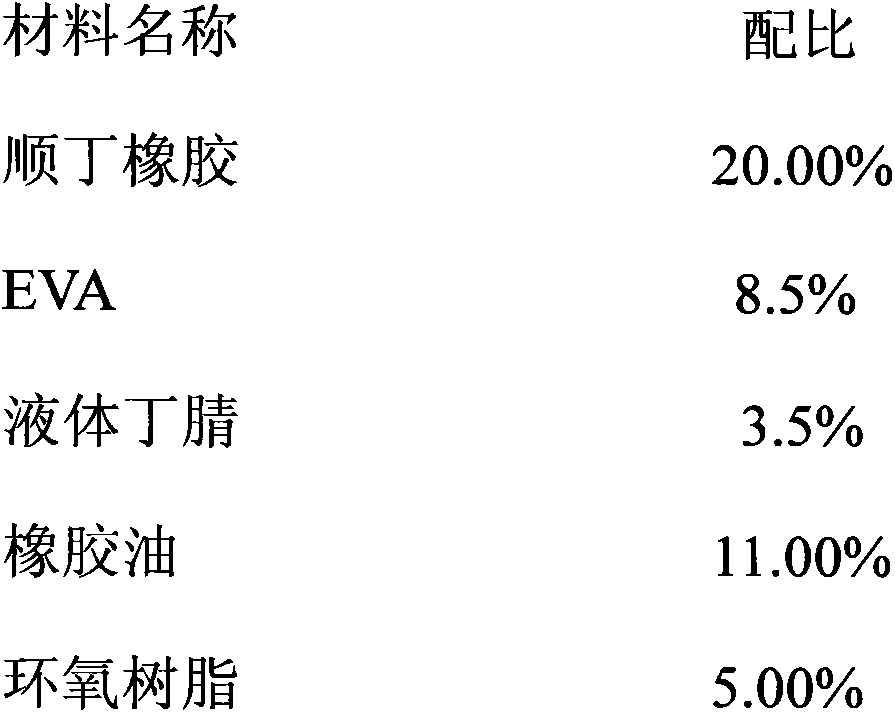

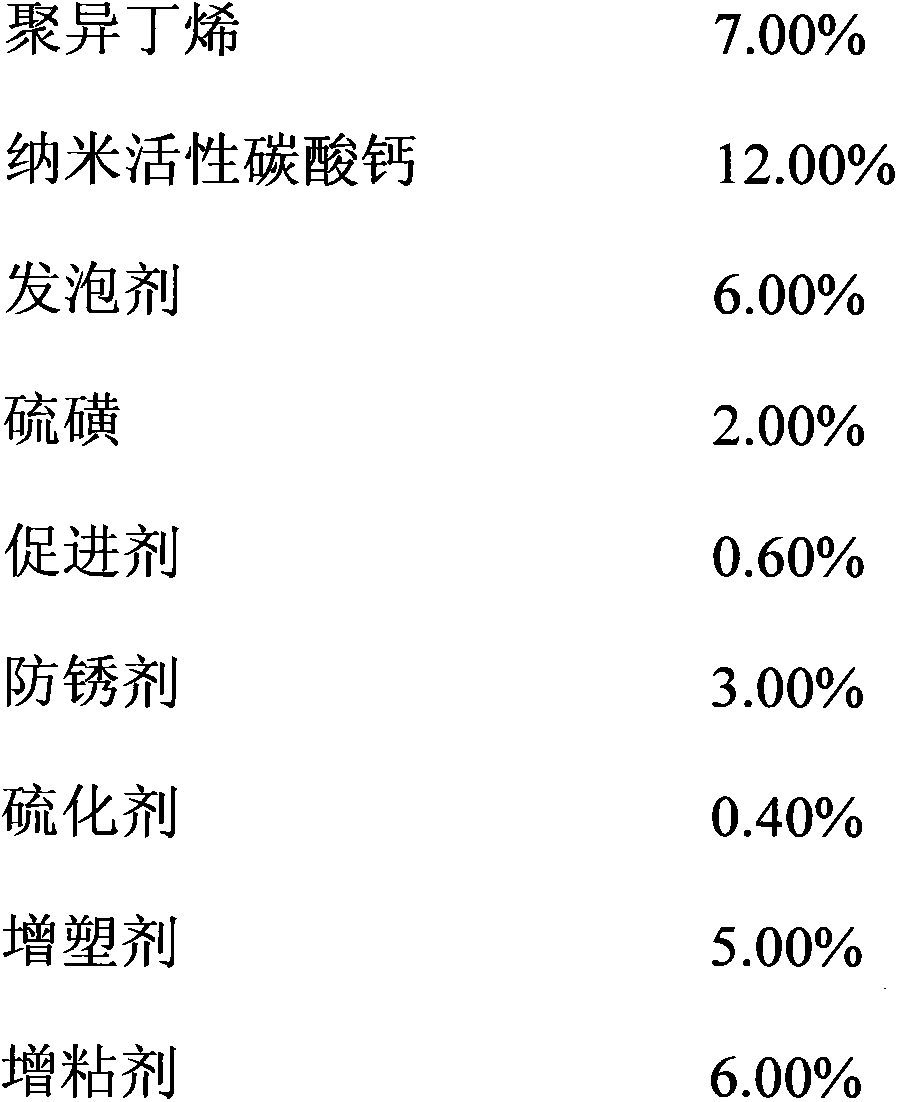

[0012] Automotive paste-like high-expansion shock-absorbing and sound-insulating adhesive and its manufacturing process are composed of butadiene rubber, EVA, liquid nitrile, rubber oil, epoxy resin, polyisobutylene, nano-active calcium carbonate, foaming agent, sulfur, accelerator, anti-corrosion Rust agent, vulcanizing agent, plasticizer, and tackifier use a pressurized kneader to mix and disperse materials. The weight ratio of this material is as follows:

[0013]

[0014]

[0015] The production process steps are as follows: Step 1: Mix the butadiene rubber and EVA in the internal mixer for 10 minutes, add rubber oil in three times to make it soften, and mix the materials evenly without small particles;

[0016] Step 2: Put the mixed material into the kneader, add liquid nitrile, knead in the kneader for 10 minutes, then add nano-active calcium carbonate, knead for 5 minutes, slowly add polyisobutylene in 3 times to ensure kneading No fine particles in the process; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com