Device for condensing methane in rotating manner

A technology of biogas and condenser, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of low condensation efficiency and high air intake requirements of generator sets, achieve low operating costs, simplify biogas dehydration process, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

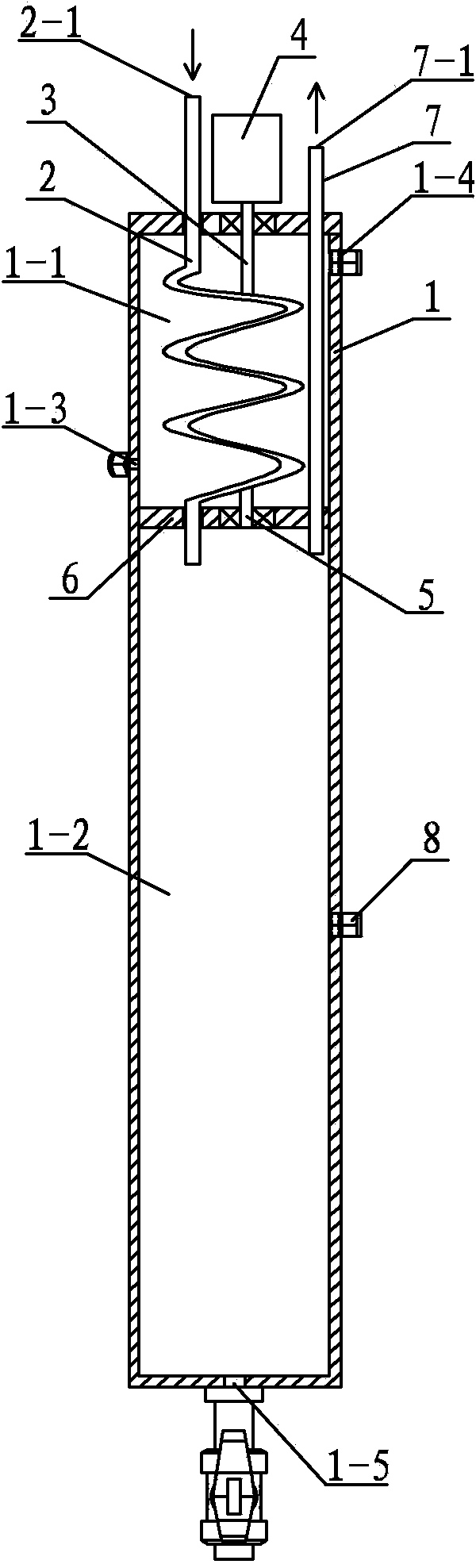

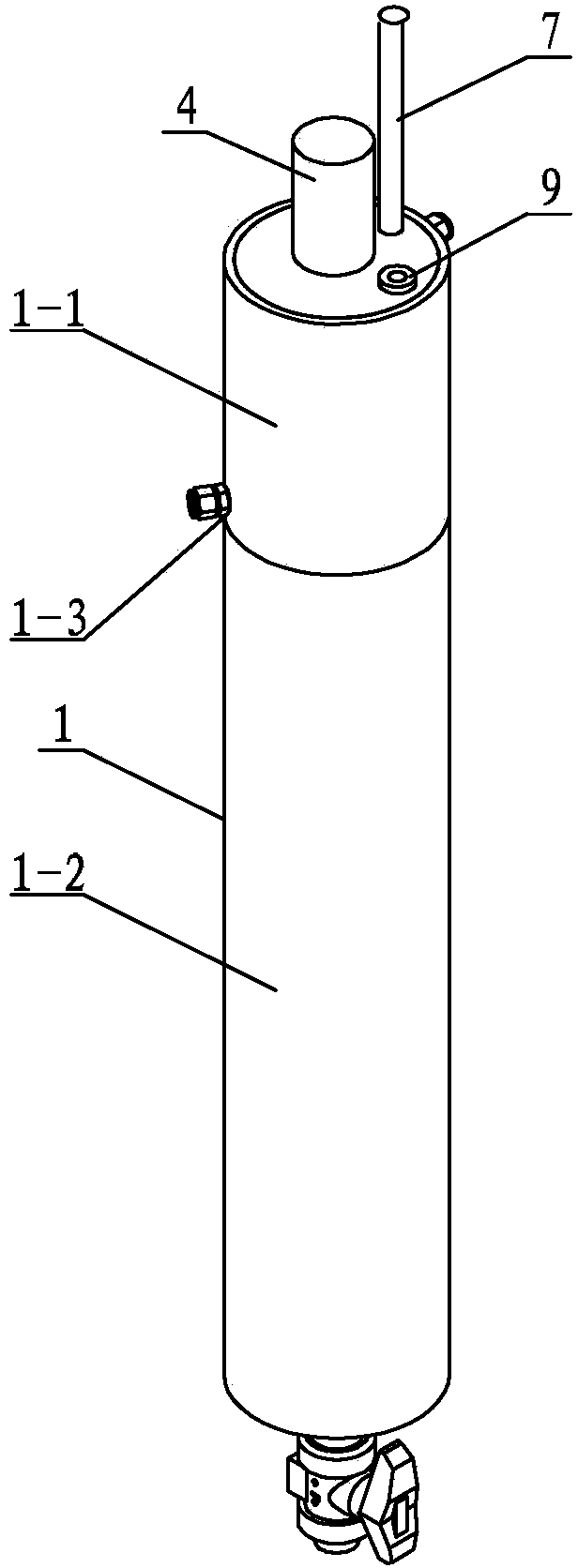

[0014] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment. This embodiment includes a condenser 1, a screw shaft 2, a drive shaft 3, a motor 4, a driven shaft 5, a baffle 6 and a biogas output pipe 7. The condenser 1 is a cylindrical structure, and the baffle The plate 6 is horizontally arranged in the condenser 1, the condensate bin 1-1 is above the baffle 6, and the condensate collection bin 1-2 is below the baffle 6, and the screw shaft 2 is set in the condensate bin 1-2. 1, the upper end of the screw shaft 2 is the biogas inlet 2-1 and passes through the top of the condenser 1, the upper end of the screw shaft 2 passes through the baffle plate 6 and is located in the condensed water collection bin 1-2, and the driving shaft 3 is installed through a bearing On the top of the condenser 1, the input end of the driving shaft 3 is connected to the output end of the motor 4, the output end of the driving shaft 3 is connected to the screw s...

specific Embodiment approach 2

[0015] Specific implementation mode two: combination figure 1 This embodiment is described. The difference between this embodiment and the first embodiment is that it also adds a liquid level gauge 8, which is arranged on the side wall of the condenser 1 and located on the upper part of the condensed water collection bin 1-2. The liquid level gauge 8 is used to monitor the liquid level of the condensed water, and when the liquid level of the condensed water reaches a certain height, it will be discharged through the drain port 1-5 of the condenser. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 2 Describe this embodiment, the difference between this embodiment and specific embodiment one is that it also adds an exhaust pipe 9, and the exhaust pipe 9 is arranged in the condensate tank 1-1, and the upper end of the exhaust pipe 9 passes through the condenser 1 The top of the exhaust pipe 9 passes through the baffle plate 6 and is located in the condensed water collection bin 1-2 at the lower end. When emergencies such as excessive pressure in the condensed water collection bin 1-2 occur, the exhaust pipe 9 is used to discharge the biogas in the condensed water collection bin 1-2. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0017] Working principle of the present invention:

[0018] The condensate enters the condensate bin 1-1 from the condensate inlet 1-3 and fills up the condensate bin, biogas enters the screw shaft 2 from the biogas inlet 2-1, starts the motor 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com