Splicing internal corner template for building

A kind of internal corner formwork and construction technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of inconvenient disassembly, concrete grout leakage, and affecting beautiful construction, so as to save formwork materials , bearing capacity without joints, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

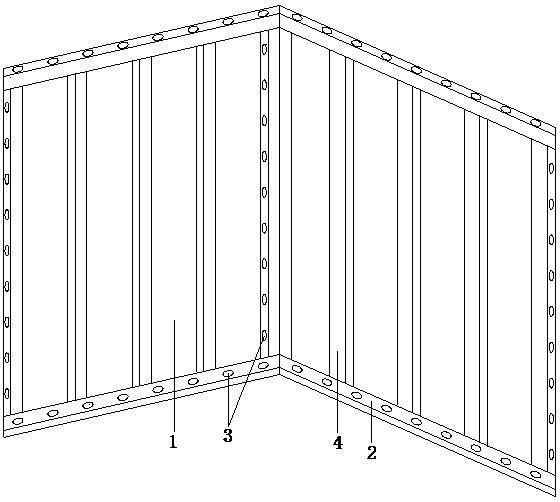

[0014] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a rectangular steel plate body 1, strip square tubes 2 are welded on the four edges of the back side of the plate body 1, and the square tube 2 is provided with evenly distributed bolt holes 3, and the two plate bodies 1 are connected from the back side. The splicing is at right angles, and the directions and positions of the bolt holes 3 on the square tubes where the two boards 1 intersect correspond to each other; the back of the boards 1 is laser welded with parallel and evenly arranged support rods 4 .

[0015] According to the needs of the building, the two plates 1 corresponding to the direction of the bolt holes 3 on the side square tube 2 are spliced so that the back is at right angles, and at the same time, the two plates 1 have a pair of internal angle structures through the installation of bolts in the bolt holes 3 Splicing, connecting the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com