Decompression valve device of lubricating oil supplementing mechanism

A technology of lubricating oil and pressure relief valve, which is applied in the direction of mechanical equipment, machines/engines, liquid variable capacity machinery, etc. It can solve problems such as unfavorable compressor normal operation, increased internal pressure of oil cup, rupture and damage, etc., to eliminate Abnormal lubricating oil level, easy processing and manufacturing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

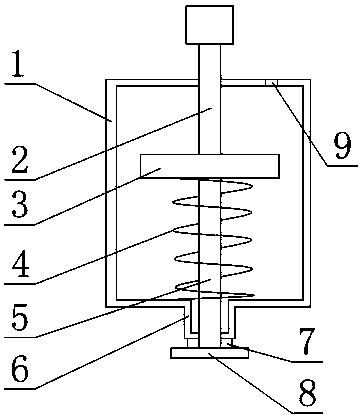

[0022] like figure 1 As shown, the pressure relief valve device of the lubricating oil replenishment mechanism includes a valve frame body 1, a pressure rod 2, a spring stopper 3, a spring 4, a pull rod 5, a rubber pad 7 and a rubber pad support block 8, and the spring stopper 3 The two ends are fixedly connected with one end of the pressure rod 2 and one end of the pull rod 5 respectively. Through holes are respectively arranged on the upper and lower ends of the valve frame 1. The pressure rod 2 forms a clearance fit with the through hole at the upper end. The pull rod 5 and the through hole at the lower end form a clearance fit, the other end of the pull rod 5 is fixedly connected to the rubber pad support block 8, and a rubber pad 7 is arranged between the rubber pad support block 8 and the valve frame body 1, and the spring 4 is arranged on the spring stopper 3 and the inner surface of the lower end of the valve frame body 1, the pressure rod 2 passes through the upper en...

Embodiment 2

[0025] This embodiment is further improved on the basis of embodiment 1, as figure 1 As shown, the pressure rod 2 and the pull rod 5 are integrated, and the pressure rod 2 and the pull rod 5 are all provided with external threads, the spring stopper 3 is provided with an internal thread through hole, and the spring stopper 3 and the The external threads are threadedly engaged.

[0026] This setting aims to realize the positional movement of the spring stopper 3 on the pull rod 5 and the push rod 2 by rotating the spring stopper 3 around the pressure rod 2 or the pull rod 5, that is, to achieve the purpose of adjusting the spring force of the spring 5 at any time.

[0027] It also includes an outer boss 6 , which is arranged at the bottom of the valve frame 1 , and the gap matching surface between the valve frame 1 and the pull rod 5 is at the bottom of the outer boss 6 .

[0028] The provided outer boss 6 is designed to accumulate lubricating oil entering the pressure relief...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com