Pneumatic forceps holder

A technology of pneumatic caliper and air inlet, applied in the direction of brake type, drum brake, brake actuator, etc., can solve the problems of maintenance and replacement, and achieve the effect of simple installation, avoiding mutual friction and small clamping range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

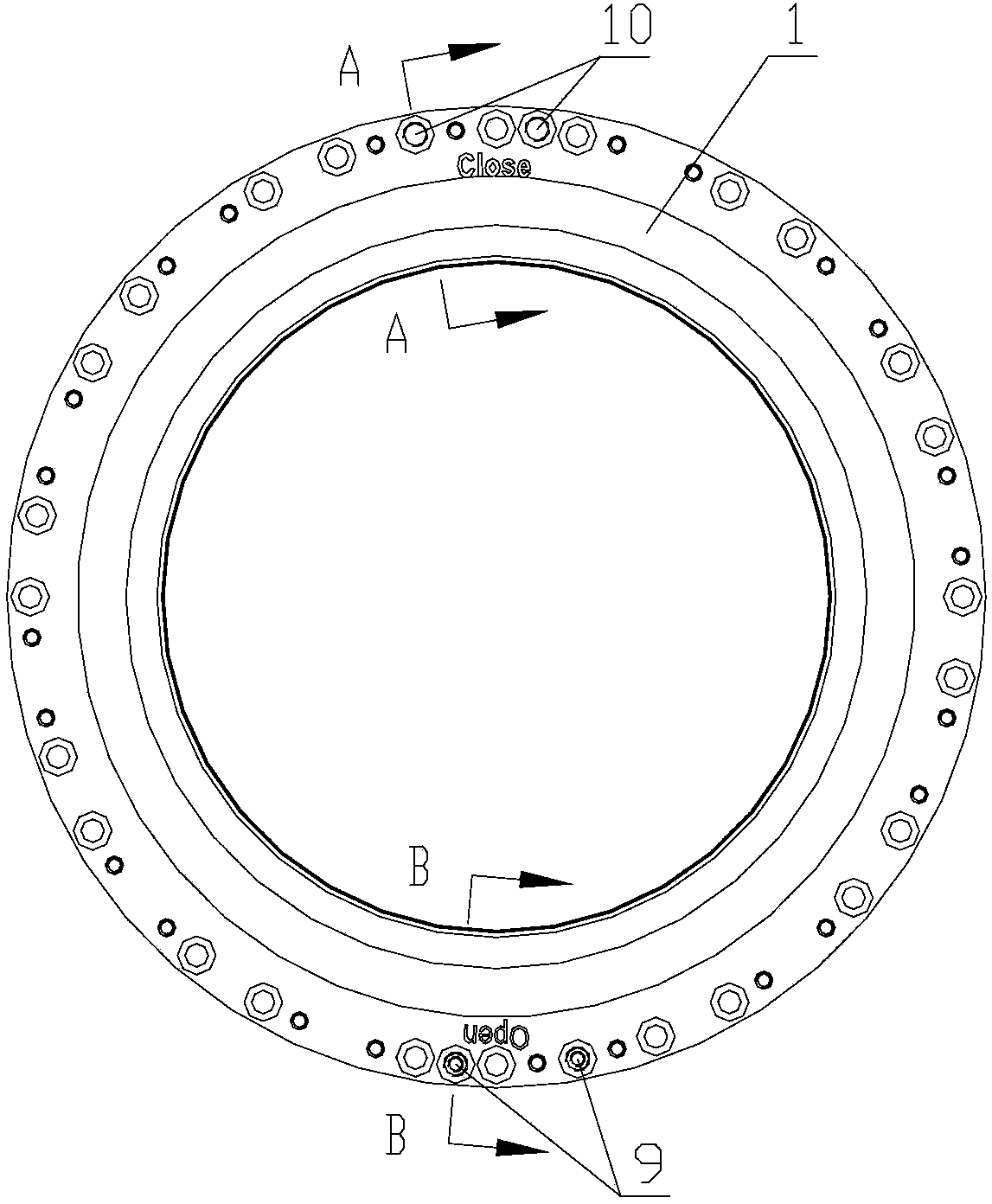

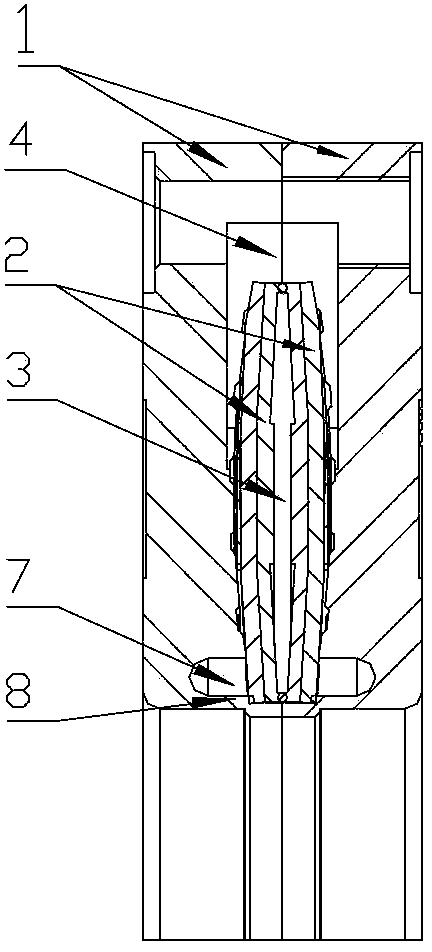

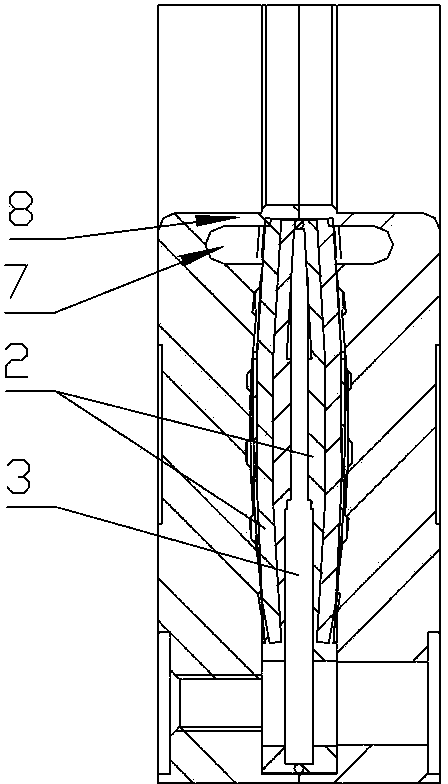

[0039] The specific embodiment of the present invention is shown in accompanying drawing, and its structure is made up of two shells 1 with the same size and symmetry and two spring bell chambers 2 with the same size and symmetry; Inside the shell 1, it is fastened by screws; an inner cavity 3 is formed between two spring bellows 2, and an outer cavity 4 is formed between the shell 1 and the spring bellows 2; a reference plane is processed on an outer surface of the shell 1.

[0040] The shell 1 is made of metal; a spring bellows installation groove 5 is processed on its inner side, and a plurality of air grooves 6 are processed on the bottom surface of the spring bellows installation groove 5; an annular groove is machined on the inner side of the shell 1 near the edge of the inner diameter 7. A squeeze locking piece 8 is formed at the inner diameter of the shell 1; a plurality of corresponding countersunk holes and threaded holes for screw installation are processed on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com