Roller backstop

A backstop and backstop technology, applied in the direction of brake type, automatic brake, mechanical energy control, etc., can solve the problems of fast wear and tear of backstop facilities, complex manufacturing structure, high production cost, and achieve reduced production cost, easy parts processing, The effect of a low number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

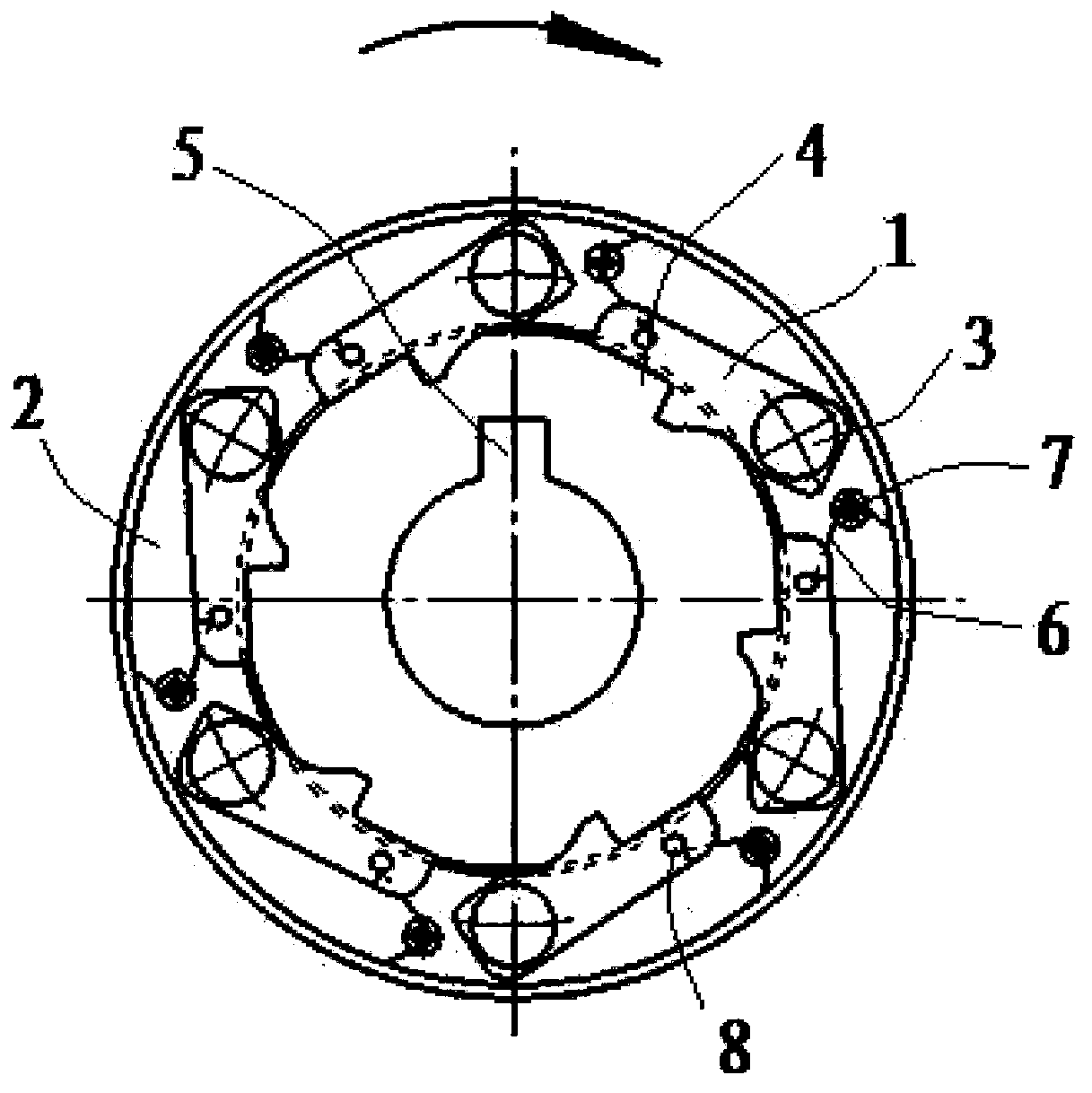

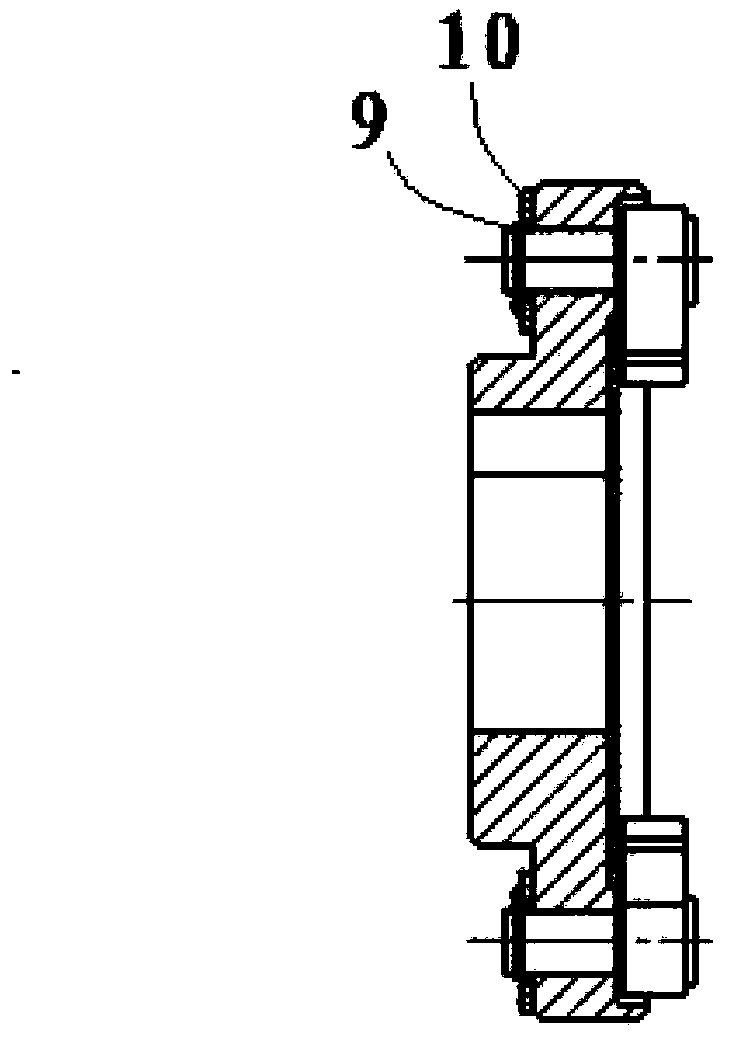

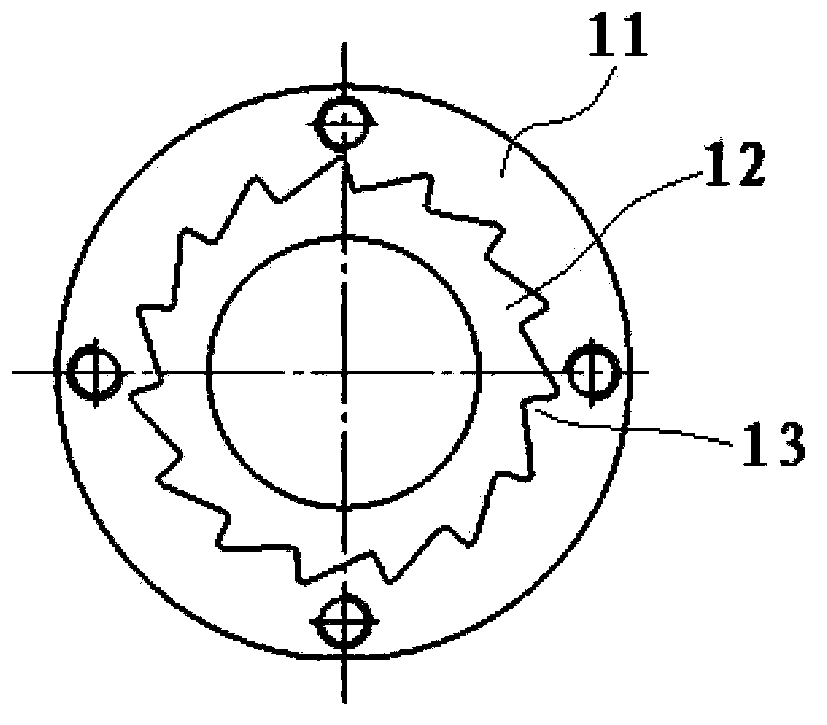

[0021] Such as Figure 1-Figure 4 , a drum backstop, comprising: a pawl plate and a ratchet plate, the pawl plate includes: a flange plate 2, a pawl 1, an elastic steel wire 6; the ratchet plate includes: a backstop wheel 12 and a backstop wheel fixed plate 11 , wherein: the middle hole of the flange 2 has a keyway 5, the pawl 1 surrounds the flange 2 and one end is connected to the front of the flange 2 near the edge of the circumference, and the other end of the pawl 1 has a 90° There is a small hole on one side of tooth mouth 4, 90° tooth mouth 4, and elastic steel wire 6 is installed on the front of flange 2 between ratchet 1 near the peripheral edge, and one end of elastic steel wire 6 is connected with the small hole at the tooth mouth end of ratchet 1 , the other end is fixed on the edge of the flange 2; the edge of the backstop wheel 12 has a 90° backstop opening 13, and the backstop wheel 12 and the backstop wheel fixed plate 11 are fixed by face-to-face center symmet...

Embodiment 2

[0028] Take the assembly on the motor as an example, as attached Figure 4 , the ratchet disc 16 is installed on the inner wall of the end cover of the motor 17, the ratchet disc 16 is fixed, and the ratchet disc 15 is fixed on the motor shaft 18 through the flat key 14. Swing it to the peripheral edge of the flange and disengage from the backstop wheel 12 of the ratchet disc 16. When the motor 17 needs to be backstopped due to various factors, the 90° tooth mouth 4 of the ratchet 1 is due to the elastic steel wire 6. function, quickly return to the working position, and can quickly mesh with the 90° backstop 13 of the backstop wheel 12, and the 90° tooth opening 4 of the ratchet 1 is pressed against the 90° backstop 13 of the backstop wheel 12 , because the ratchet disc 16 is fixed on the motor 17, it can quickly stop reversing and realize the backstop effect.

[0029] The drum backstop provided by the present invention has a simple and lightweight structure, and does not ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com