A laser alignment device and alignment method thereof

A laser centering and laser instrument technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve problems such as complex centering methods, short service life, complicated calculation process, etc., to overcome shortcomings and limitations, improve Long service life, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

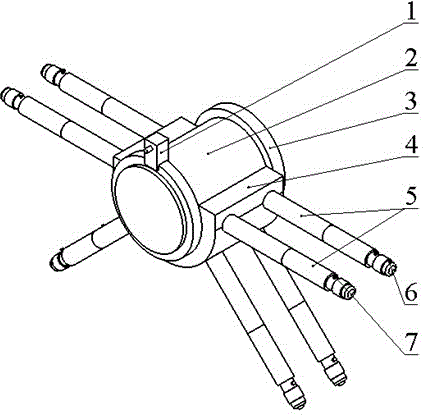

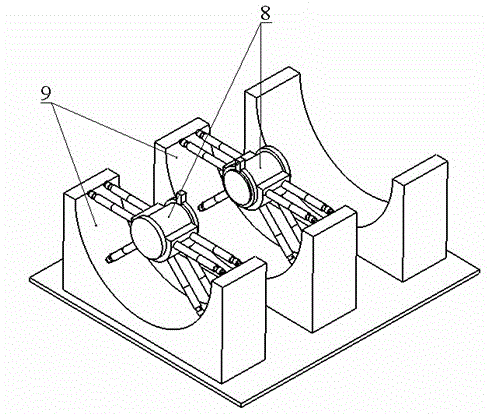

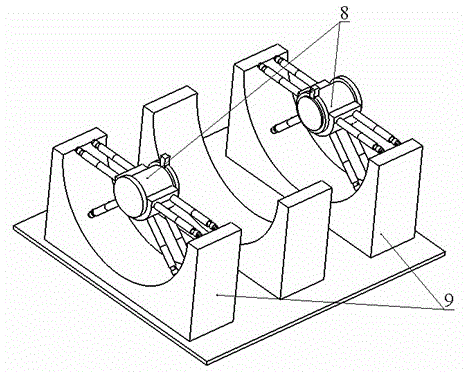

[0027] It can be seen from the accompanying drawings that a laser centering device includes: a laser device 1, a dummy shaft 2, a dummy bearing bush 4, a supporting leg and a balance device, and is characterized in that: the laser device is installed on a dummy shaft, Threaded holes are respectively provided at 0°, 180°, 225° and 315° on both sides of the bearing bush, and the supporting legs are connected to the false bearing bush through threads, and the extension line of the supporting legs passes through the center of the circle. The laser instrument 1 is equipped with a laser emitting device and receiver. Through the adjustment of the four supporting legs, the axis of the dummy shaft 2 and the axis of the bearing bush 9 to be tested can be on the same horizontal line, and the centering operation is performed by a laser instrument.

Embodiment 2

[0029] As an improvement of the present invention, the balance device is composed of a cylindrical balance weight 3 , which is arranged on the other side of the dummy shaft 2 . After adopting this design, the weight on both sides of the dummy shaft 2 can be balanced, the laser device 1 can work normally, and the cylindrical balance weight 3 will not affect the rotation of the dummy shaft 2 in the dummy bearing bush 4 . The rest of the structural features and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0031] As an improvement of the present invention, the balance device is composed of a laser instrument 1, which is arranged on the other side of the false axis 2. After adopting this design, the dummy shaft 2 can maintain a balanced state when working, the laser device 1 can work accurately, and can perform centering operations to both sides with the center as the standard, which can improve the centering efficiency. All the other structures and advantages are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com