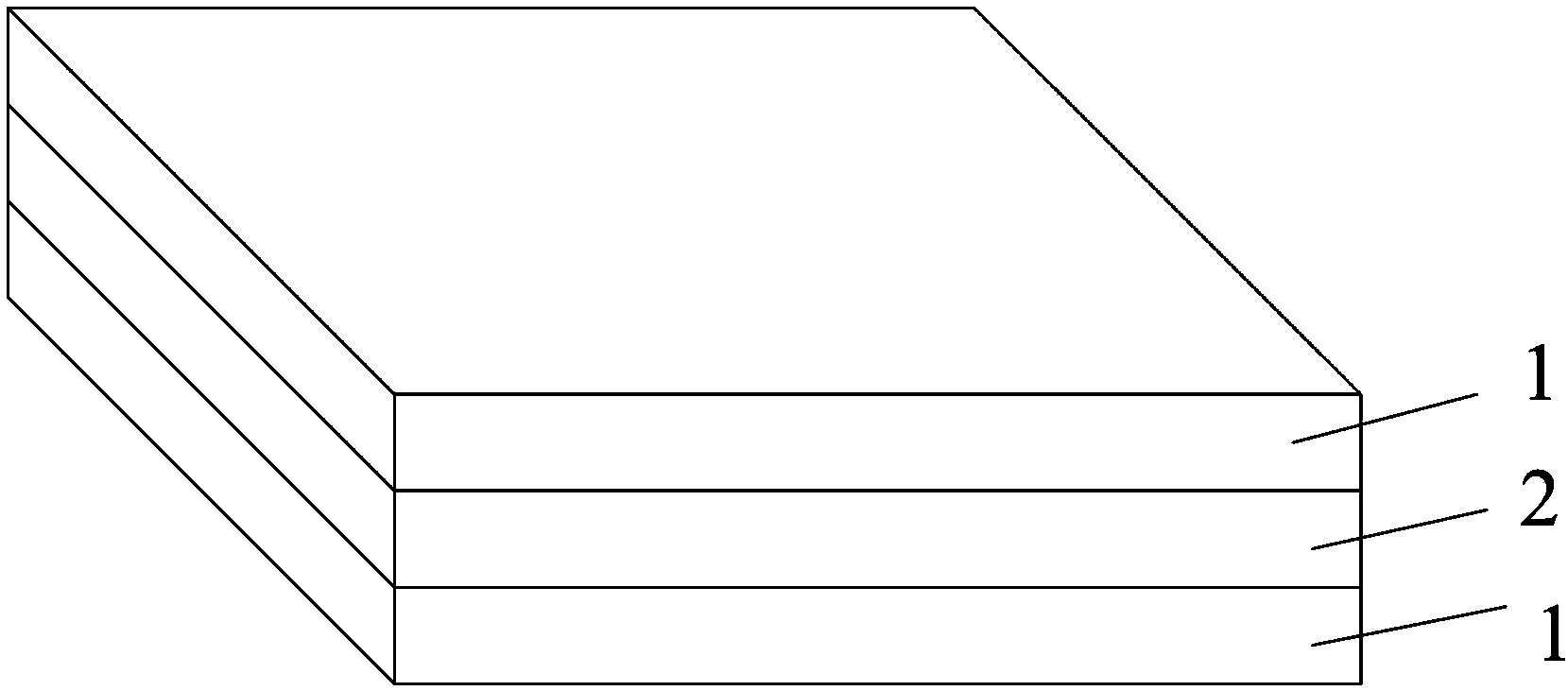

Heterogeneous cementing core model with high-permeability layer and preparation method thereof

A core model and heterogeneous technology, which is used in the preparation of test samples, permeability/surface area analysis, measurement devices, etc. Realize reservoir applicability and realize the effect of evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a heterogeneous cemented core model with a high permeability layer suitable for evaluating the seepage characteristics of slow-swelling particles with a particle size of 0.2 mm. The manufacturing method includes the following steps:

[0030] 1. Determine the particle size of the fully expanded slow-expanding granules. Through the water-absorbing swelling experiment, the particle size of the fully-expanded slow-expanding granules with a particle size of 0.2 mm is about 0.3 mm;

[0031] 2. Statistical law shows that the pore size is not less than 1 / 3 of the gel particle size, and the gel particles can be injected into the formation under a certain pressure, so it is determined that the particle size of the sodium chloride solid particles used to make the high permeability layer is not less than 0.1mm ;

[0032] 3. Assume that according to the reservoir conditions, the matrix permeability is required to be 3 Darcy;

[0033] 4. According to the emp...

Embodiment 2

[0051] The present embodiment provides a rock core model with a high-permeability layer suitable for evaluating the seepage characteristics of slow-swelling particles with a particle size of 1 mm, and its manufacturing method includes the following steps:

[0052] 1. Determine the particle size of the fully expanded slow-expanding granules. Through the water-absorbing swelling experiment, the particle size of the fully-expanded slow-expanding granules with a particle size of 1 mm is about 1.5 mm;

[0053] 2. Statistical law shows that the pore size is not less than 1 / 3 of the gel particle size, and the gel particles can be injected into the formation under a certain pressure. Therefore determine that the particle diameter of the sodium chloride solid particle that makes high permeability layer is not less than 0.5mm;

[0054] 3. According to the geological conditions of the studied reservoir, it is assumed that the matrix permeability is 20 Darcy;

[0055] 4. According to the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com