Framework type 8-shaped photoelectric composite cable

A photoelectric composite cable, figure-8 technology, applied in the direction of insulated cables, communication cables, cables, etc., can solve the problems of high optical fiber dispersion, large energy loss, poor mechanical performance and environmental performance, etc., to achieve compact structure, low energy loss, Good mechanical and environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

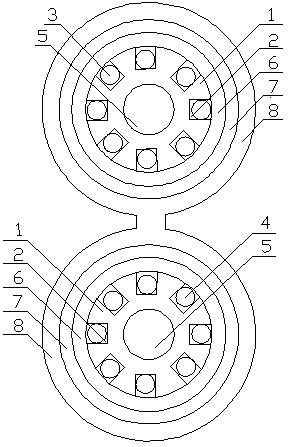

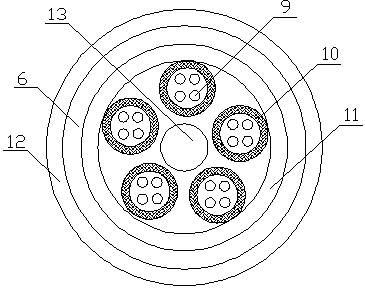

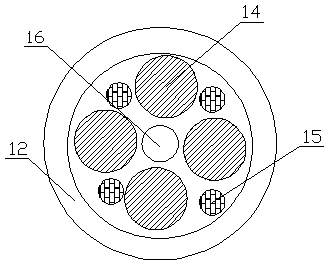

[0019] Such as figure 1 As shown, a frame-type 8-shaped photoelectric composite cable has an outer sheath 8 in the shape of "8", and the "8"-shaped outer sheath 8 is composed of two "0"-shaped structural units, and each "0"-shaped Each structural unit includes a skeleton 1, a skeleton groove 2, a "0"-shaped structural unit central reinforcement 5, a metal strip 6 and an armor layer 7. The "0"-shaped structural unit central reinforcement 5 is located at the center of the skeleton 1, and the skeleton 1 is surrounded by a plurality of skeleton grooves 2, and the outside of the skeleton 1 is covered with a metal strip 6, an armor layer 7 and an outer sheath 8 sequentially from the inside to the outside, and the optical cable 3 and the cable 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com