Method for manufacturing light-variable light-emitting component

A manufacturing method and technology of light-emitting components, applied in the direction of electrical components, electric solid-state devices, semiconductor devices, etc., can solve problems such as cost-consuming, not in line with economic benefits, and affect the applicability of light-emitting component modules, so as to reduce the probability of inoperability, The effect of increasing the diversity of luminous colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

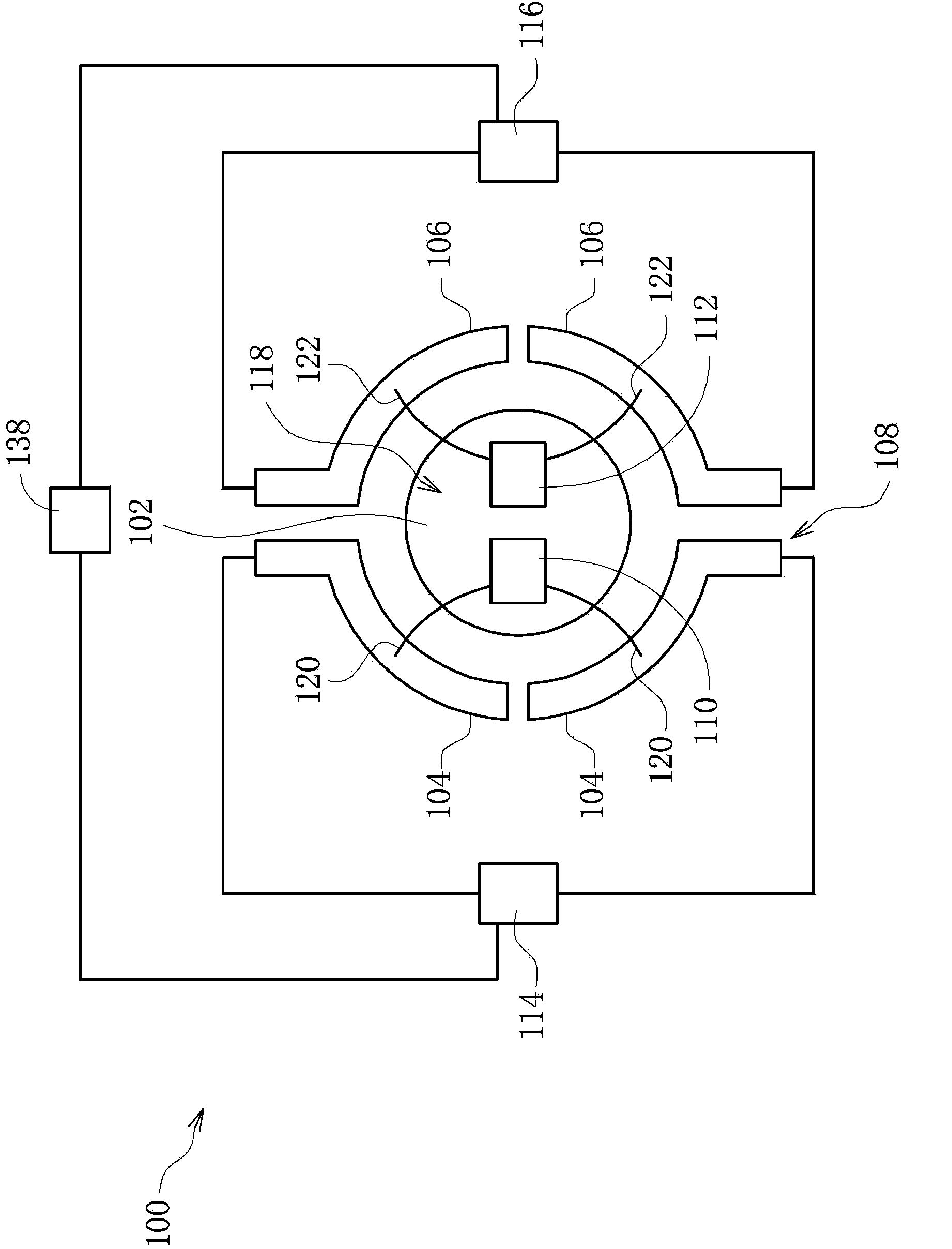

[0039] The invention discloses a dimming light-emitting component, which has wide applicability. In order to make the narration of the present invention more detailed and complete, refer to the following description and cooperate Figure 1 to Figure 4 attached drawings.

[0040] Please refer to figure 1 , which is a schematic top view showing a dimming light-emitting component according to an embodiment of the present invention. In one embodiment, the dimming light-emitting component 100 mainly includes a bracket 108 , at least two light-emitting chips 110 and 112 , and at least two independent power sources 114 and 116 . The independent power sources 114 and 116 are respectively electrically connected to the corresponding light-emitting chips 110 and 112 to supply the required power.

[0041] In one embodiment, the bracket 108 may include a chip carrier 102 and at least two pairs of pins 104 and 106 .

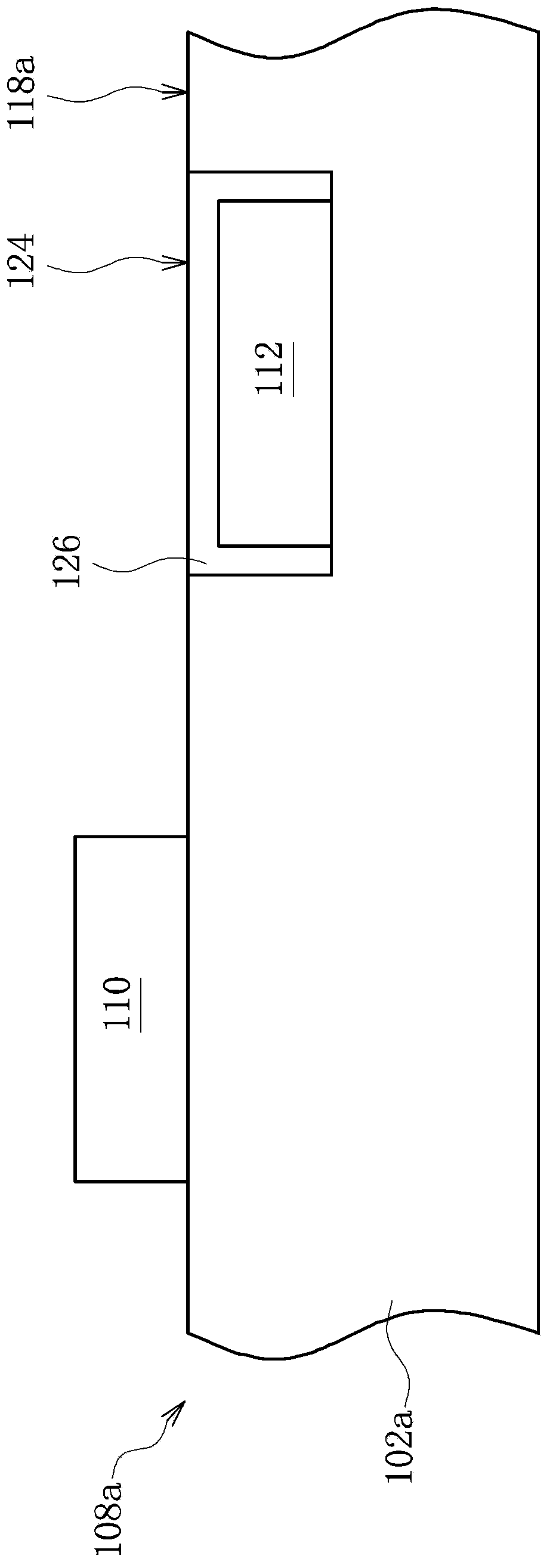

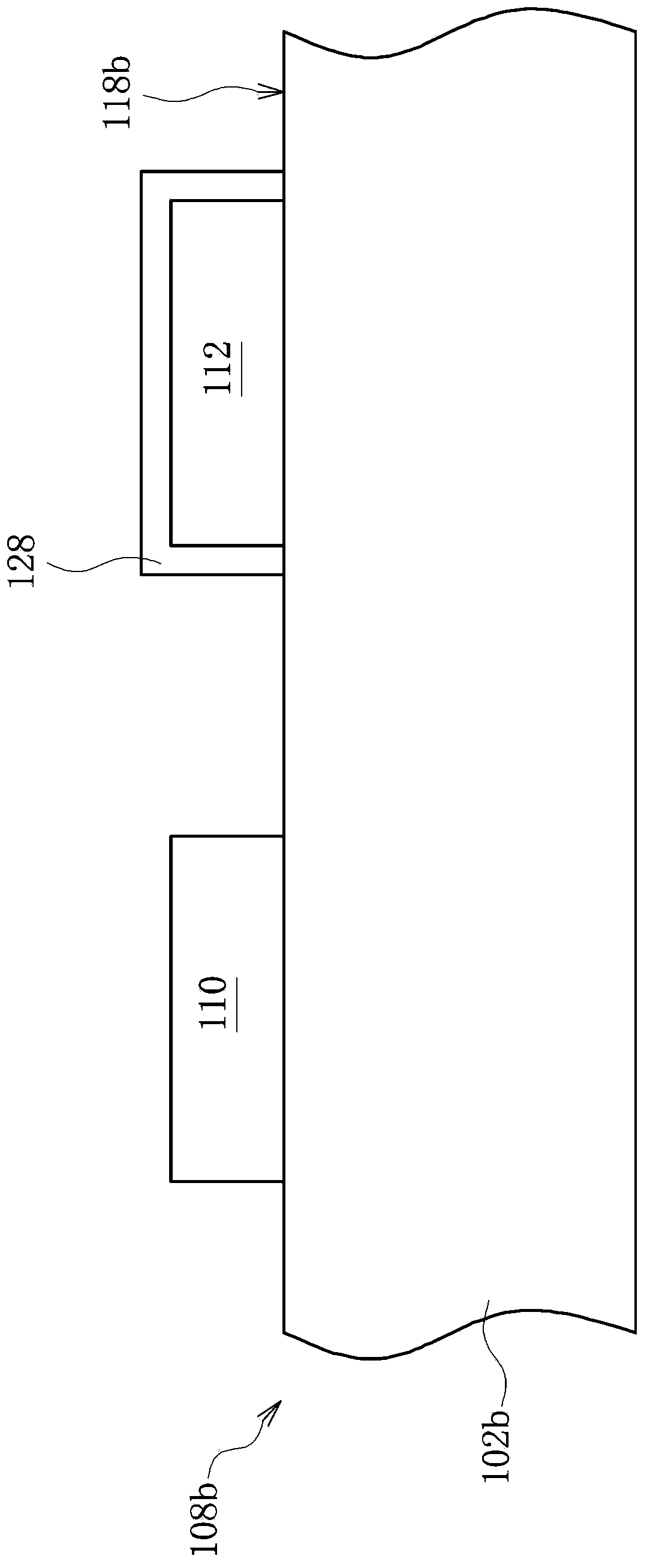

[0042] Please refer to figure 2 , which is a cross-sectional view o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com