Device for high-density molding and method for high-density molding of mixed powder

A mixed powder, high-density technology, which is applied in the direction of transportation and packaging, material forming presses, manufacturing tools, etc., can solve the problems of reduced quality of powder compacts, insufficient density, insufficient mechanical strength, etc., to improve fluidity , to achieve the effect of simplification of the device and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

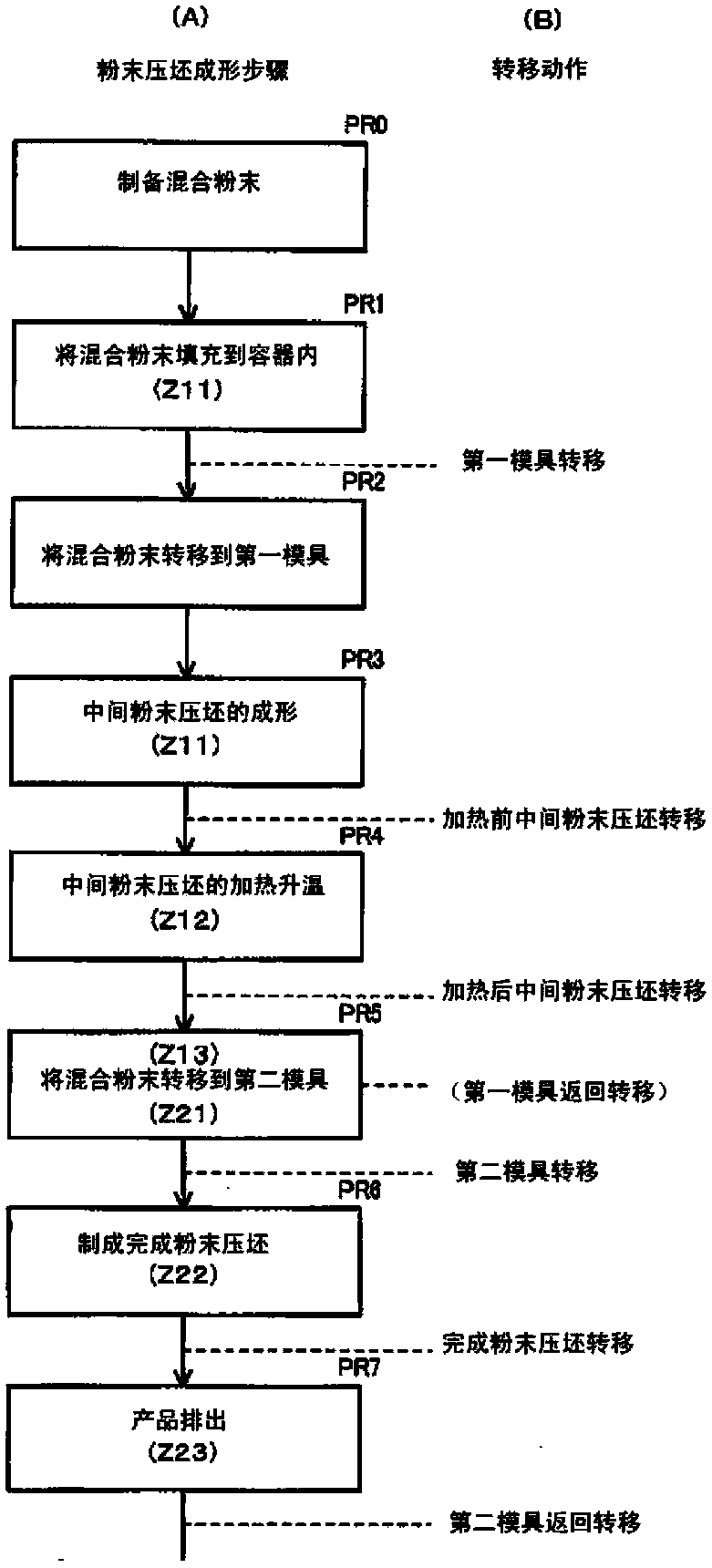

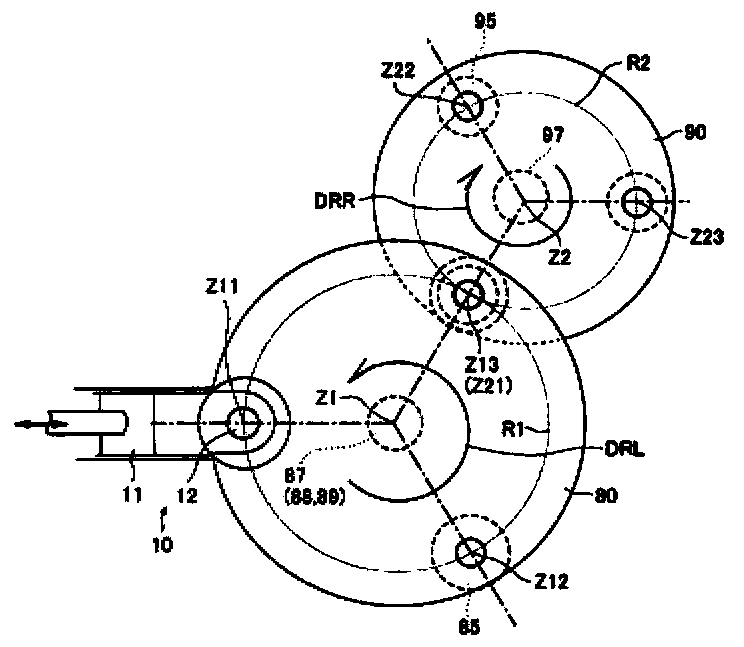

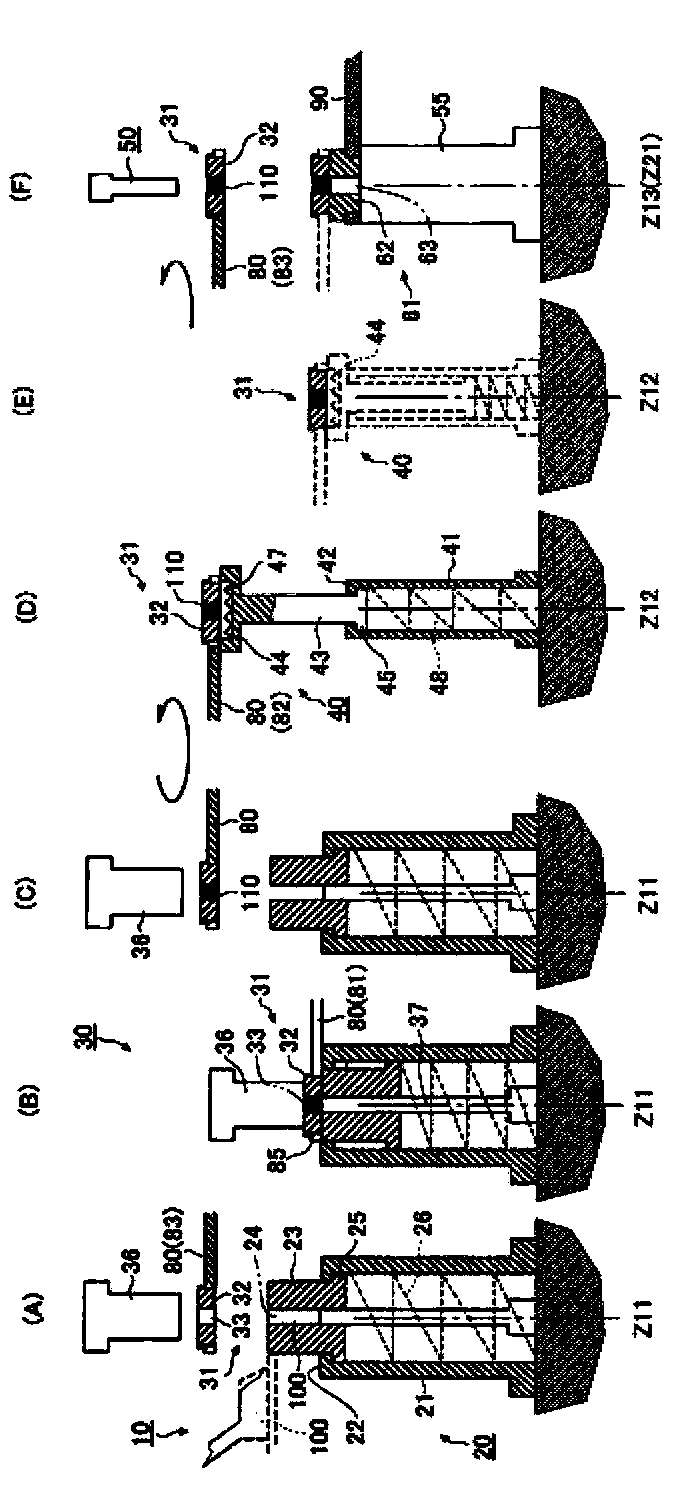

[0067] The high-density molding device 1 of this mixed powder, such as Figure 1 ~ Figure 6E As shown, it has a mixed powder supply machine 10, a container 23, a mixed powder transfer device (lower punch 37), a first press forming machine 30, a heating and heating machine 40, an intermediate powder compact transfer device (extrusion rod 50), The second pressure molding machine 60 and the product discharge device 70 are arranged so that the high-density molding method of the mixed powder can be stably and reliably implemented. The high-density molding method of the mixed powder is composed of the following steps: figure 1 The mixed powder filling step (PR1) of filling the mixed powder 100 shown in (A) into the container 23; the mixed powder transfer step (PR2) of transferring the mixed powder 100 into the first mold 31; The mixed powder 100 applies the first pressing force P1 to form the intermediate powder compact forming step (PR3) of the mixed powder intermediate compact (so...

no. 2 approach )

[0182] The implementation is as Figure 7 , Figure 8 shown. When the basic structure and functions are set to be the same as those in the first embodiment ( Figure 1 ~ Figure 6E ) are the same, but the second preheating device 64 is provided on the second mold 61 (die 62 ) constituting the second press molding machine 60 . Furthermore, a first preheating device 34 is provided on the first mold 31 (die 32 ) constituting the first press molding machine 30 .

[0183] That is, it is set to preheat the second mold 61 and prevent the temperature drop of the heated intermediate green compact 110 . In addition, the first mold 31 can be preheated and the intermediate green compact 110 can be preheated. In this embodiment, both the first preheating device 34 and the second preheating device 64 are provided, but either one may be provided depending on the working temperature environment and the like.

[0184] in addition, Figure 7 ( Figure 8 ) related to the first embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com