Synchronously-ejecting welding mechanism for lower welding of steel bar trusses

A technology of steel bar truss and welding mechanism, applied in the field of steel bar truss, can solve the problems of the lower welding mechanism being unable to lift, unable to lift at the same time, unable to handle welding requirements of different specifications, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

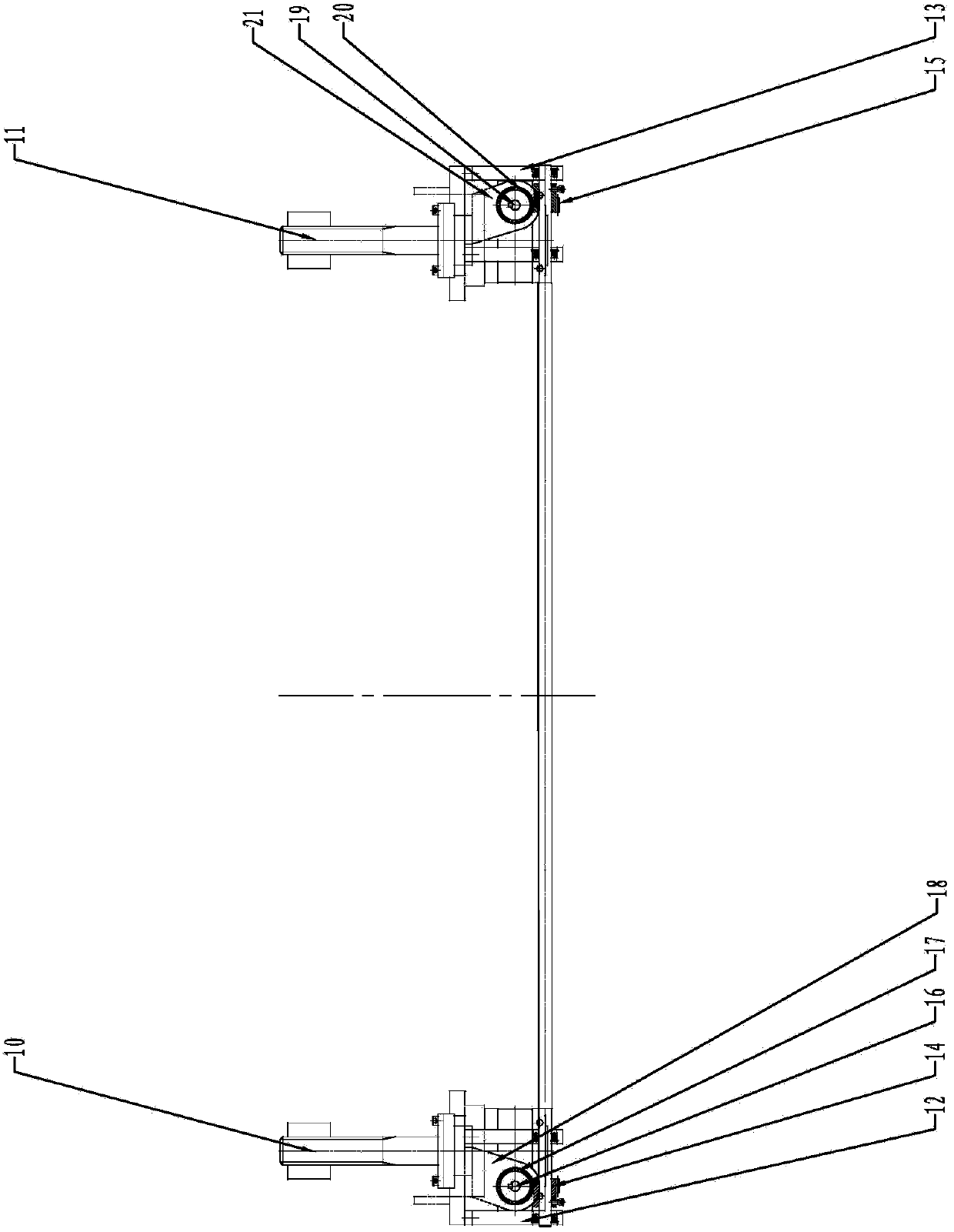

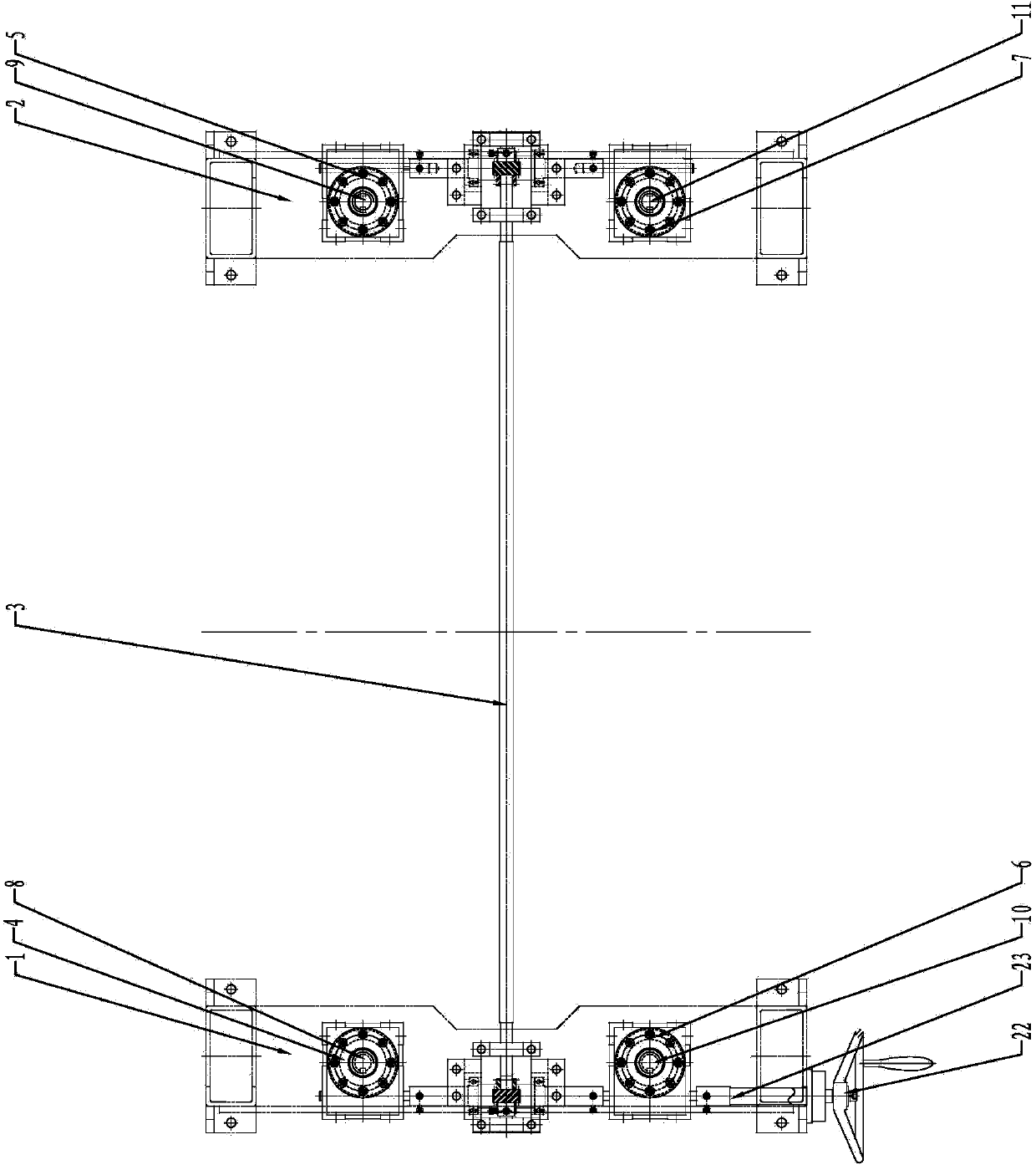

[0012] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings:

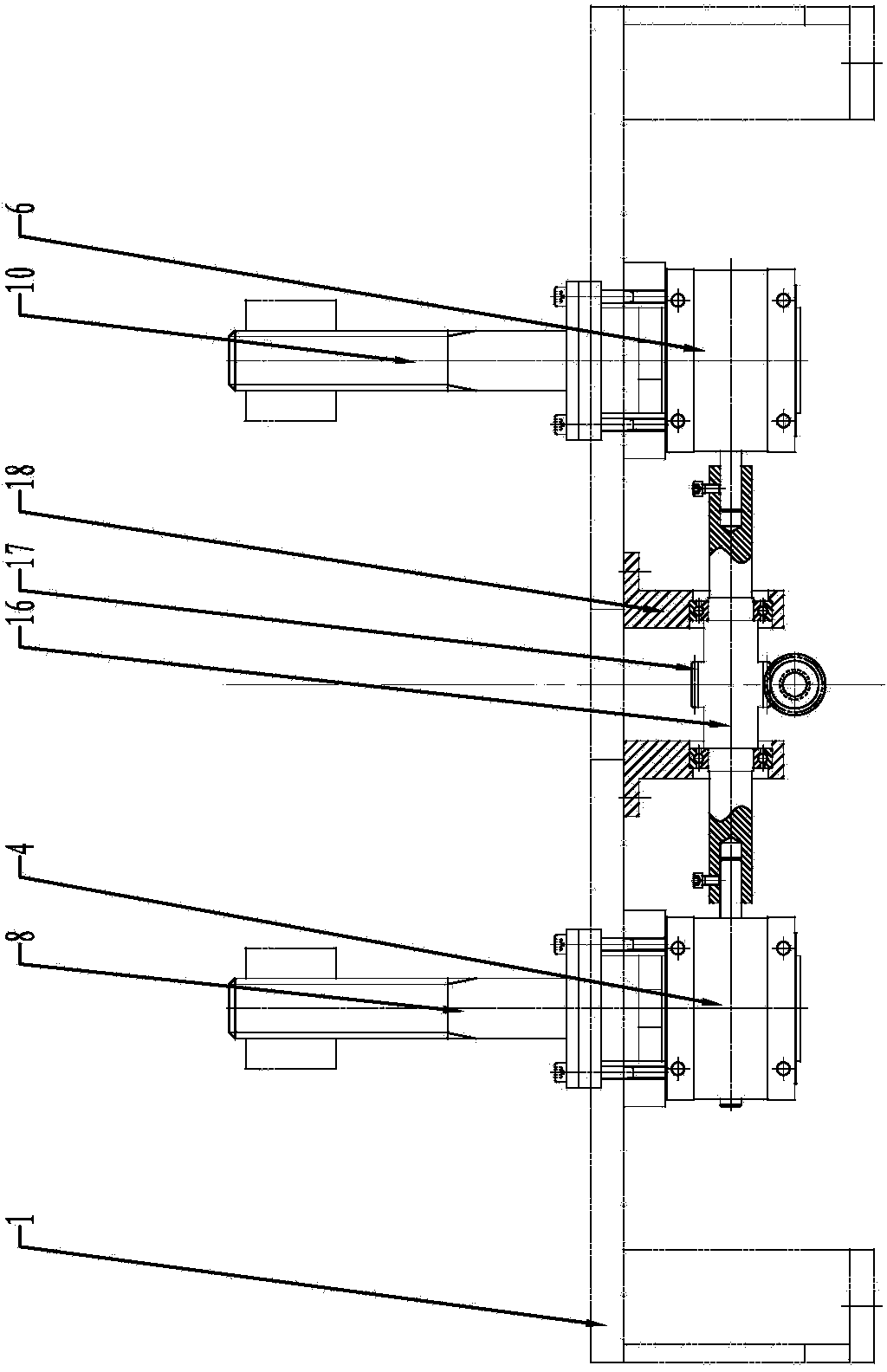

[0013] like Figures 1~3 As shown, the present invention mainly includes a synchronizing link 3, and both ends of the synchronizing link 3 are connected to the first frame 1 and the second frame 2 through the first synchronizing link seat 12 and the second synchronizing link seat 13 respectively. Two ends of the synchronizing link 3 are respectively connected with the first synchronizing gear 14 and the second synchronizing gear 15 .

[0014] The first frame 1 is symmetrically provided with a first reducer 4 and a third reducer 6, the first reducer 4 and the third reducer 6 are connected by a first transmission link 16, and both ends of the first transmission link 16 pass through The first transmission link seat 18 is connected to the first frame 1 . A first helical gear 17 is provided in the middle of the first transmission link 16 , and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com