Fixing ring

A fixed ring and sheet technology, applied in the field of fixed rings, can solve problems such as the failure to know the damage of the fixed ring in time, economic loss, wafer damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to describe the technical solution of the above invention in more detail, specific examples are listed below to demonstrate the technical effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

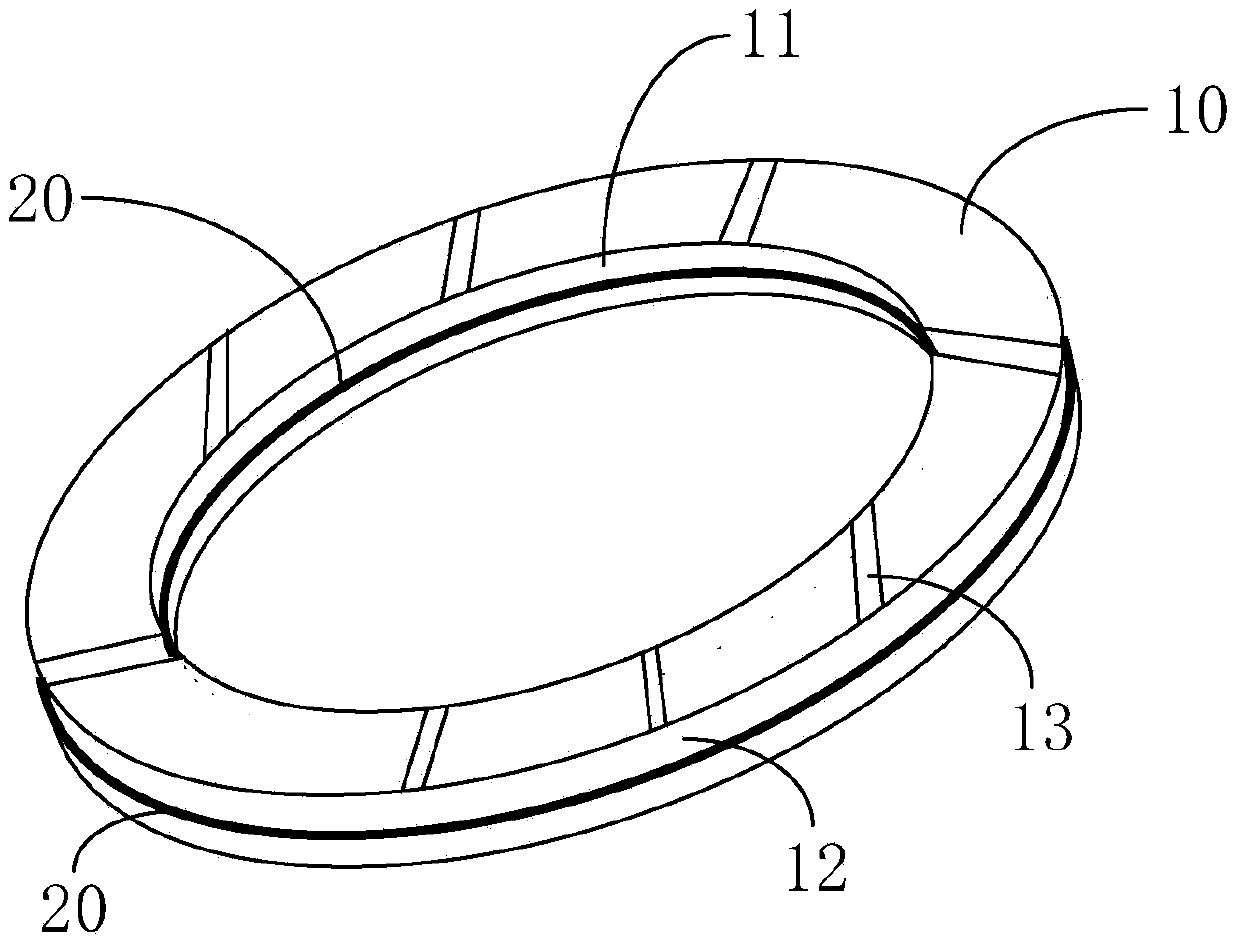

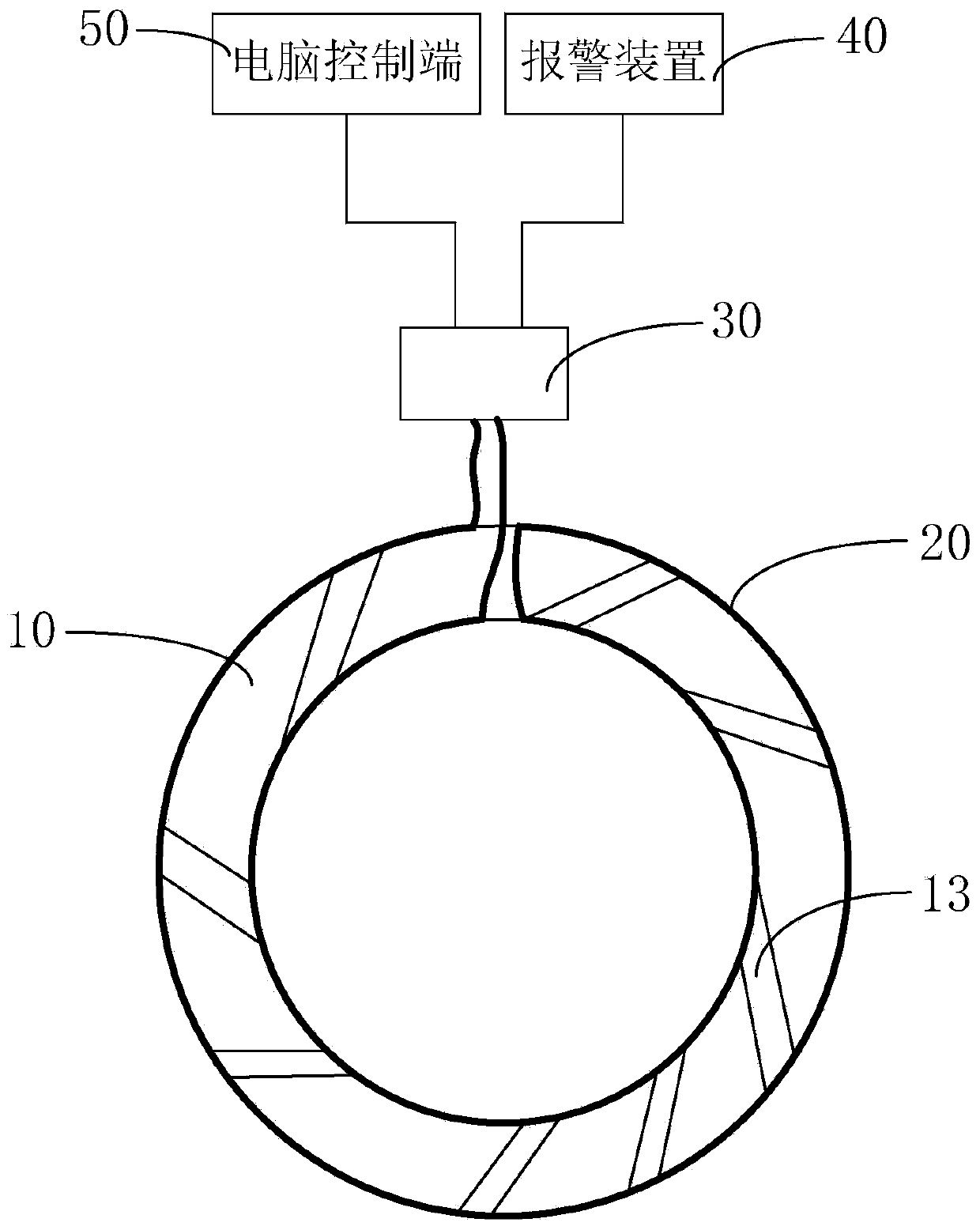

[0015] The fixed ring provided by the present invention, such as Figures 2 to 3 As shown, it includes a sheet-shaped ring 10, and also includes a wire 20, a pulse current signal sensor 30 and an alarm device 40. The wire 20 is arranged on the inner wall 11 and the outer wall 12 of the thin-shaped ring 10. Of course, the wire 20 The arrangement is not limited to image 3 The winding method shown is sufficient as long as it can achieve the technical effect that the wire 20 will be broken if the sheet-shaped ring 10 is damaged. Both ends of the wire 20 are respectively connected to the input end of the pulse current signal sensor 30 , and the output end of the pulse current signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com