Paper cutting device of printer

A paper cutting device and printer technology, applied in metal processing, etc., can solve the problems of contact wear between the moving knife and the fixed knife surface, small paper cutting ability, and short service life, so as to improve working capacity, prolong service life, and reduce wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

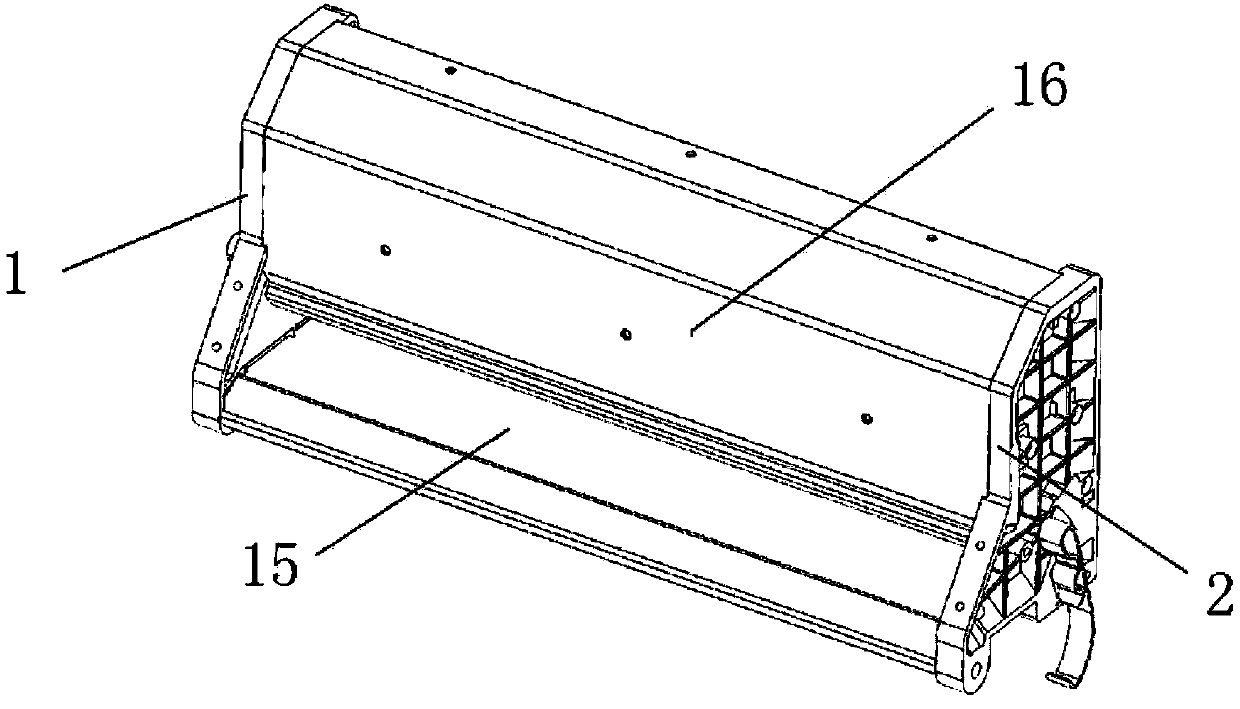

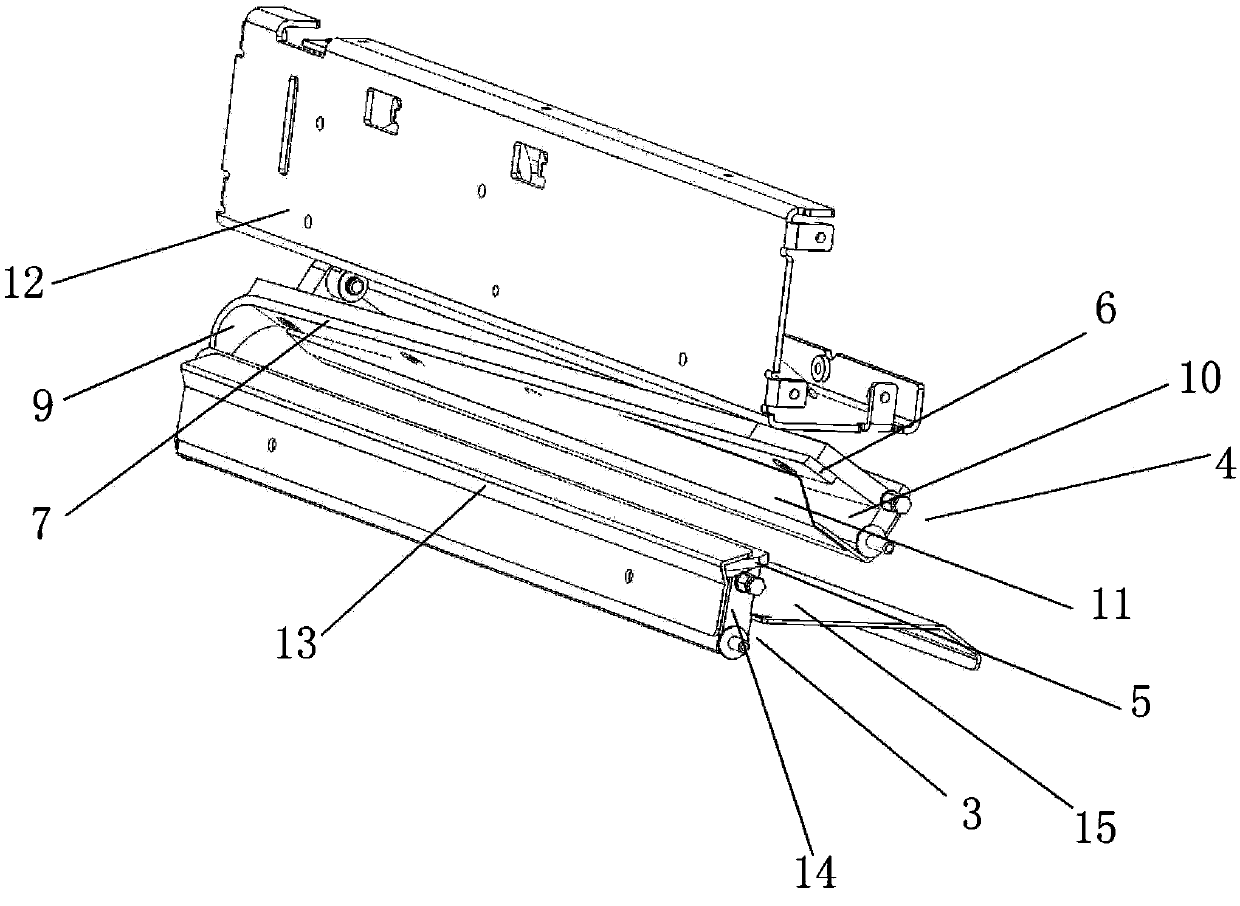

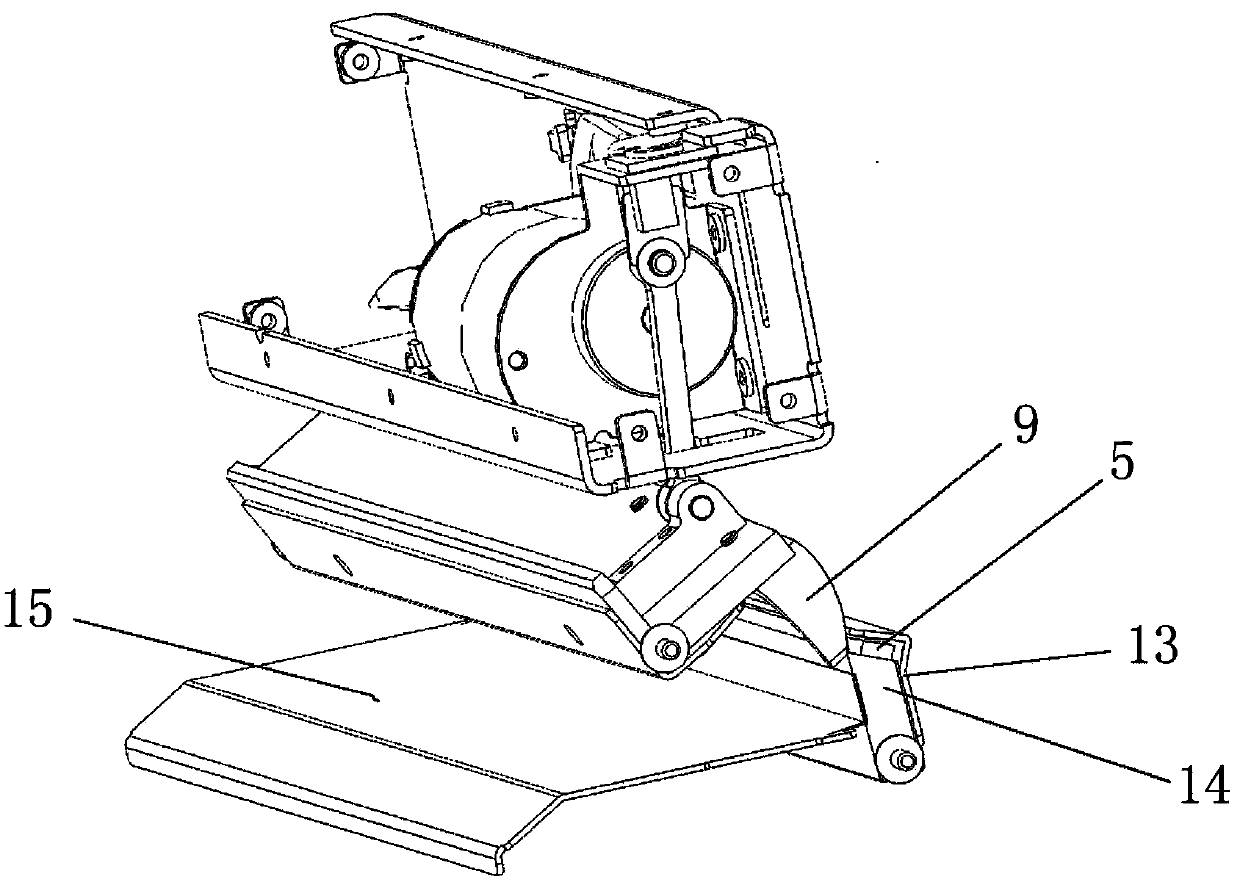

[0019] refer to figure 1 , figure 2 and image 3 , a paper cutting device for a printer of the present invention comprises left and right cutter brackets 1 and 2, and a fixed knife group 3 and a moving knife group 4 that cooperate with each other are respectively installed on the left and right cutter brackets 1 and 2, said A fixed blade 5 is installed on the fixed knife group 3, and the two ends of the movable knife group 4 are pivotally connected with the left and right cutter brackets 1 and 2 respectively, and the swing end of the movable knife group 4 is equipped with a corresponding matching blade 5. The movable blade 6, the movable blade 7 of the movable blade is laterally inclined, the fixed blade 5 has a fixed blade 8, the lateral projection of the movable blade coincides with the lateral projection of the fixed blade, wherein the lateral projection of the movable blade is arc-shaped, Its center of circle coincides with the center of the pivot joint at the two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com