Arc-shaped top pressure drive device

A driving device and arc-shaped technology, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., to ease the impact, ensure the quality of mold release, and prevent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

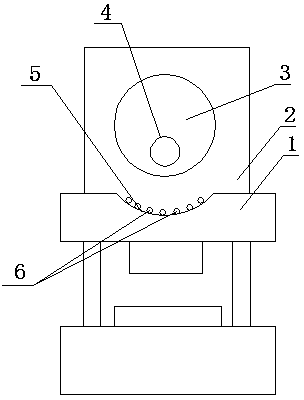

[0011] As shown in the figure: the arc-shaped top pressure driving device includes a compression molding machine 1, and the compression molding machine 1 performs compression molding from top to bottom, and also includes a press support 2, a pressing wheel 3, and a rotating shaft 4 The press bracket 2 is arranged above the press molding machine 1, the press bracket 2 is provided with a drive motor, the drive motor drives the press wheel 3 to rotate through the shaft 4, the press wheel 3 is an eccentric wheel, and the press wheel 3 pushes the press mold Machine 1 is pressed down. A downwardly concave arc-shaped groove 5 is provided at the contact part between the top of the molding machine 1 and the pressing wheel 3.

[0012] There is no ball 6 in the arc groove 5.

[0013] Through the rapid rotation of the eccentric wheel, the pressing mold and the continuous downward movement can be realized to realize the pressing mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com