A kind of production method of hot-dip galvanized magnesium alloy steel plate

A production method and alloy steel plate technology, applied in the field of steel plate processing, can solve the problems of high production cost and poor corrosion resistance, and achieve the effects of low cost, low surface friction coefficient and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

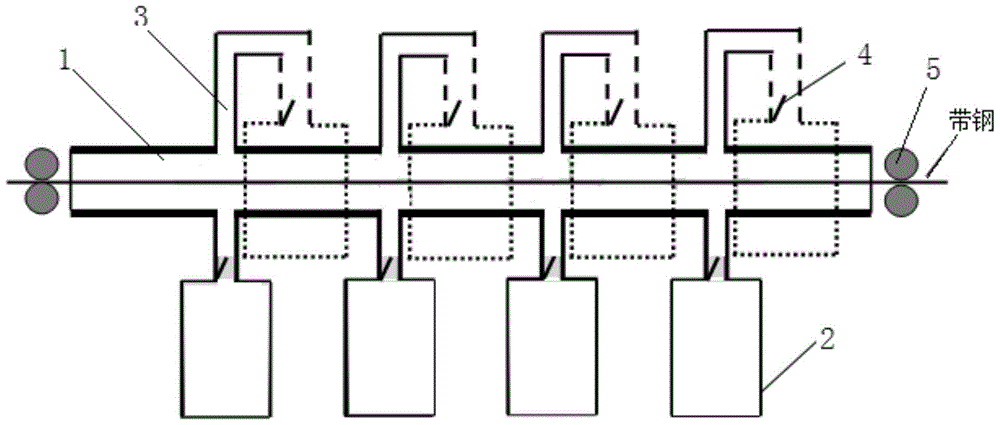

[0027] A production method of a hot-dip galvanized magnesium alloy steel plate, the steps of which are as follows:

[0028] 1) IF steel is used as the substrate, and the specification is 0.8×1700m.

[0029] 2) The substrate first undergoes surface cleaning (hot water rinsing, electrolytic cleaning, and alkali cleaning in sequence), and after the surface residue is completely removed, it enters the annealing furnace for recrystallization annealing treatment, and the annealing temperature is 820°C.

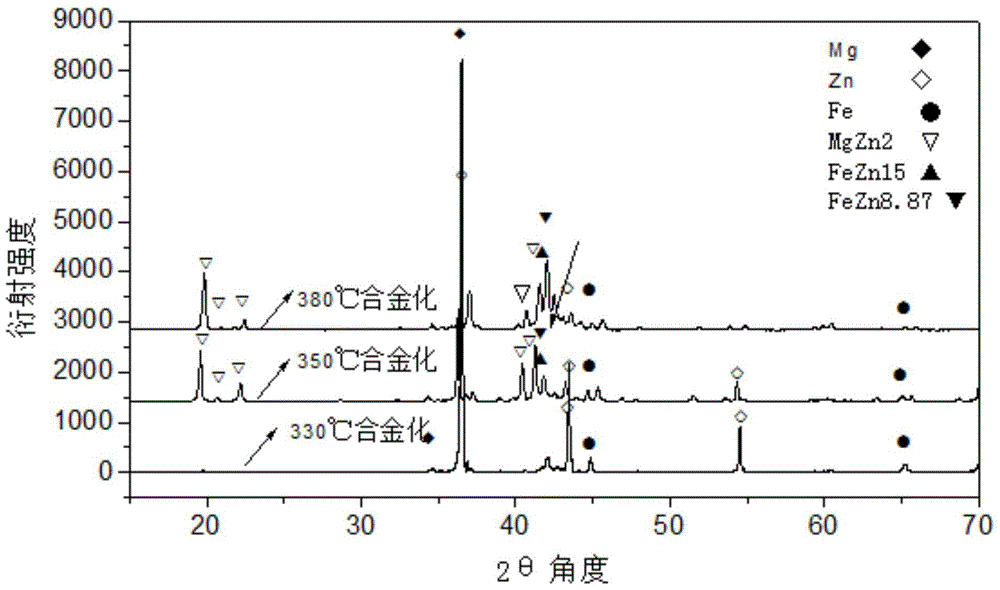

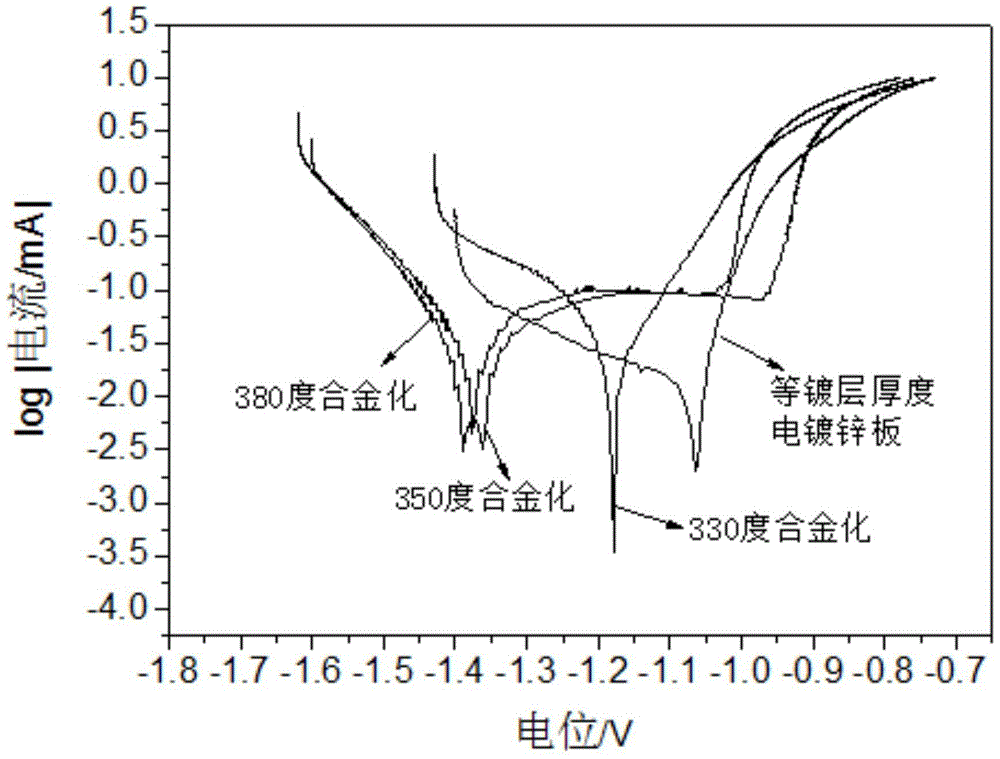

[0030] 3) Control the temperature of the strip steel after annealing at 470°C, enter the zinc pot for hot-dip galvanizing treatment, control the running speed of the strip steel at 150m / min during galvanizing, control the temperature of the zinc pot at 460°C, and the aluminum in the zinc liquid The weight content is controlled at 0.21%, the weight content of magnesium is controlled at 1%, and the rest is zinc and unavoidable impurities. Among them, the impurity Fe must be controlled...

Embodiment 2

[0038] 1. a production method of hot-dip galvanized magnesium alloy steel plate, its steps are as follows:

[0039] 1) Choose cold-rolled DP strip steel as the substrate;

[0040] 2) The substrate first undergoes surface cleaning to remove surface residues and then enters an annealing furnace for recrystallization annealing at 840°C to obtain the required mechanical properties;

[0041] 3) Control the temperature of the strip steel after annealing at 530°C, enter the zinc pot for hot-dip galvanizing treatment, control the running speed of the strip steel at 95m / min during galvanizing, control the temperature of the zinc pot at 458°C, and the aluminum in the zinc liquid The weight content is controlled at 0.19%, the weight content of magnesium is controlled at 3%, and the rest is zinc and unavoidable impurities. Among them, the impurity Fe must be controlled below 0.01%, and the thickness of the surface zinc layer is controlled by adjusting the pressure of the nitrogen gas knif...

Embodiment 3

[0047] A production method of a hot-dip galvanized magnesium alloy steel plate, the steps of which are as follows:

[0048] 1) Select cold-rolled TRIP strip steel as the substrate;

[0049] 2) The substrate first undergoes surface cleaning to remove surface residues and then enters an annealing furnace for recrystallization annealing at 780°C;

[0050] 3) Control the temperature of the strip steel after annealing at 485°C, enter the zinc pot for hot-dip galvanizing treatment, control the running speed of the strip steel at 60m / min during galvanizing, control the temperature of the zinc pot at 462°C, and the aluminum in the zinc liquid The weight content is controlled at 0.25%, the weight content of magnesium is controlled at 6%, and the rest is zinc and unavoidable impurities. Among them, the impurity Fe must be controlled below 0.01%, and the thickness of the surface zinc layer is controlled by adjusting the pressure of the nitrogen gas knife. The thickness of the zinc layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com