Crane and slewing bearing structure thereof

A technology of slewing support and crane, which is applied to cranes and other directions, can solve the problems of difficult guarantee of welding quality, deformation of the bottom plate 14 under pressure, and reduced reliability of cranes, and achieves reasonable stress, long service life, and reduced welding deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

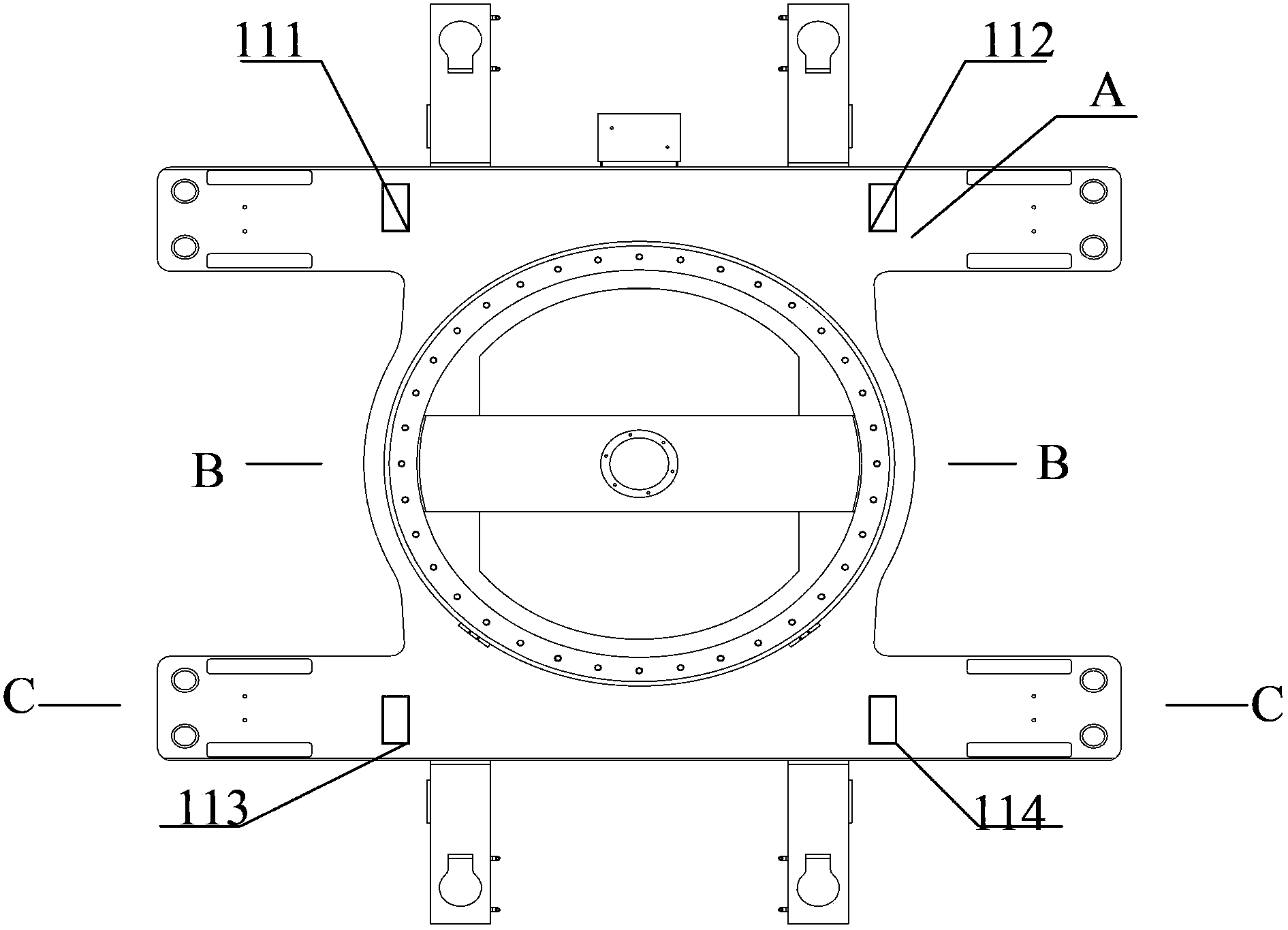

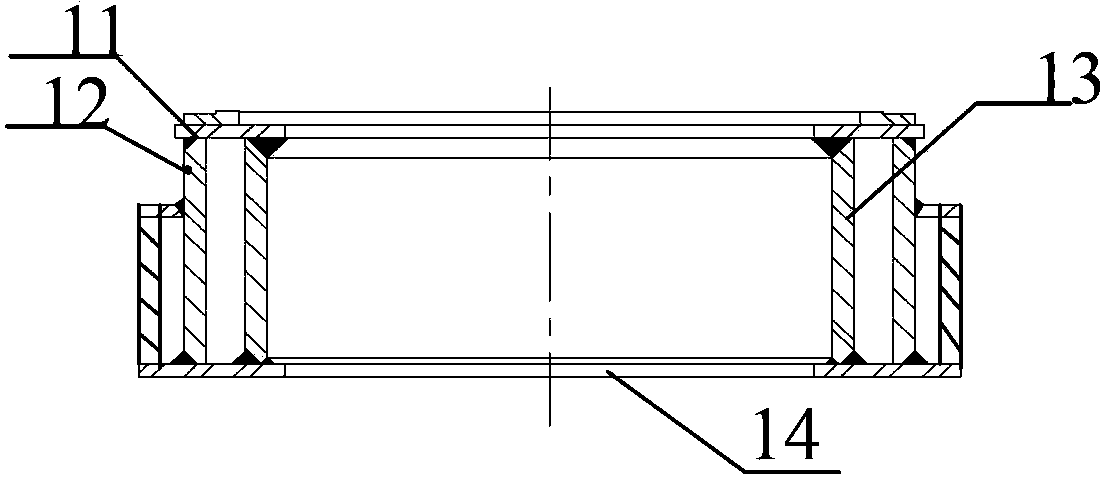

[0021] One of the core purposes of the present invention is to provide a slewing support structure for a crane. In the slewing support structure, the inner cylinder and the outer cylinder are welded separately, the inner cylinder is welded to the bottom plate, the outer cylinder is welded to the connecting plate, and the connecting plate The support plate is welded with the bottom plate, and the distance between the support plate and the inner cylinder is greater than the distance between the outer cylinder and the inner cylinder, so that the force structure of the bottom plate of the slewing support structure is more reasonable, and the slewing support structure is reduced. When the welding deformation of the bottom plate. Another object of the present invention is to provide a crane equipped with the above-mentioned slewing support structure.

[0022] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com