A construction method for overlaying concrete prefabricated slabs on airport pavement

A construction method and technology of prefabricated panels, applied in the directions of roads, roads, pavement details, etc., can solve problems such as suspension of navigation, and achieve the effect of ensuring construction quality, smooth pavement, and normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

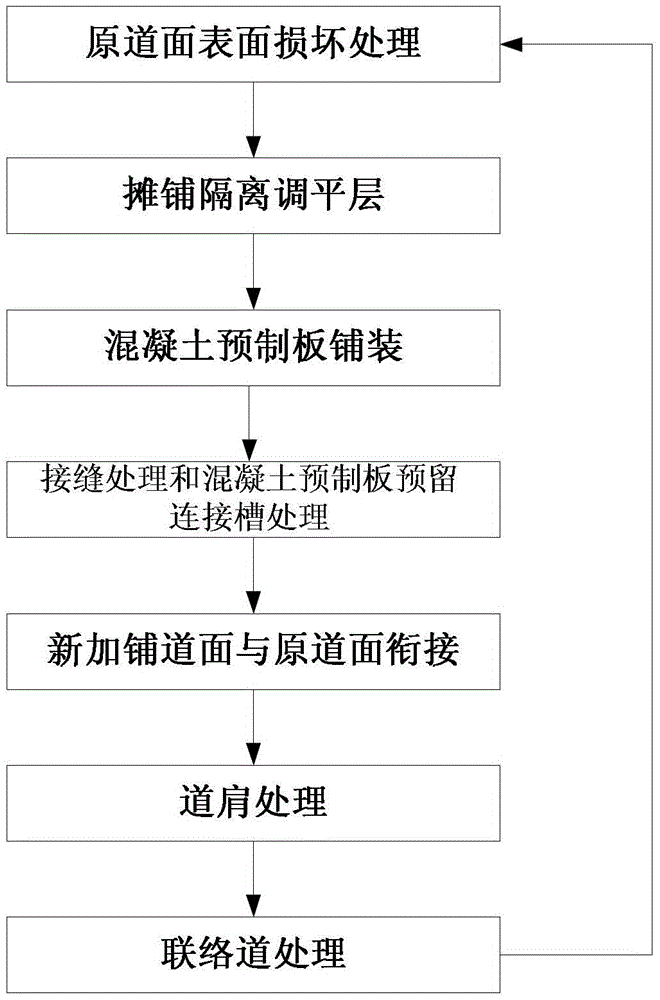

[0035] A construction method for overlaying concrete prefabricated slabs on airport pavement, such as figure 1 As shown, its construction method includes the following steps:

[0036] Step 1 Damage treatment of the original pavement surface: the original pavement is cement concrete pavement,

[0037] A) Use a cutting machine to cut the damaged area of the original road surface into a regular pentagon,

[0038] B) Use a breaker to break the original road surface in the rectangular area, remove the damaged part to the hard layer, and form a repair pit

[0039] C) Remove the original road surface materials and floating dust in the repair pit, and leave no loose gravel, floating ash, oil, sewage and other sundries on the base,

[0040] D) Use quick-setting quick-hardening mortar to fill and repair pits, vibrate and compact with a flat plate, and smooth the surface;

[0041] Step 2 Pave the isolation leveling layer:

[0042] A) Pave an isolated leveling layer on the surface o...

Embodiment 2

[0053] A construction method for non-stop laying of prefabricated concrete slabs on airport pavements, such as figure 1 As shown, its construction method includes the following steps:

[0054] Step 1 Damage treatment of the original pavement surface: the original pavement is an asphalt concrete pavement,

[0055] A) Use a cutting machine to cut the damaged area of the original pavement into a regular rectangle with an extension of 30cm,

[0056] B) Use a small milling machine to break the original pavement in the rectangular area, remove the damaged part to a hard layer, and form repair pits,

[0057] C) Remove the original pavement materials and floating dust in the repaired pit and groove, and leave no loose gravel, floating ash, oil, sewage and other debris on the base.

[0058] D) The bottom and four walls of the repair pit are evenly coated with sticky oil, and the asphalt mixture is used for layered paving and compaction. The thickness of a single compaction is not m...

Embodiment 3

[0071] A construction method for non-stop laying of prefabricated concrete slabs on airport pavements, such as figure 1 As shown, its construction method includes the following steps:

[0072] Step 1 Damage treatment of the original pavement surface: the original pavement surface is cement concrete pavement,

[0073] A) Use a cutting machine to cut the damaged area of the original pavement into regular hexagons

[0074] B) Use a breaking pick to break the original road surface in the rectangular area, and remove the damaged part to a hard layer to form a repair pit

[0075] C) Remove the original pavement material and floating dust in the repair pit, and the base does not leave loose gravel, floating ash, oil, sewage and other debris

[0076] D) Use fast-setting and fast-hardening mortar to fill the repair pits, vibrate and compact with a flat plate, and smooth the surface

[0077] Step 2 Paving the isolation leveling layer:

[0078] A) Pave the isolation leveling layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com