Combined load shedding type sound barrier for high speed railway

A technology for high-speed railways and sound barriers, applied in construction, noise absorption devices, etc., can solve the problems of loose fixing bolts, poor overall noise reduction effect of railway noise, and reduce the noise reduction effect of sound barriers on medium and low frequency noise. The effect of reducing pulsating pressure, increasing service life, and improving noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

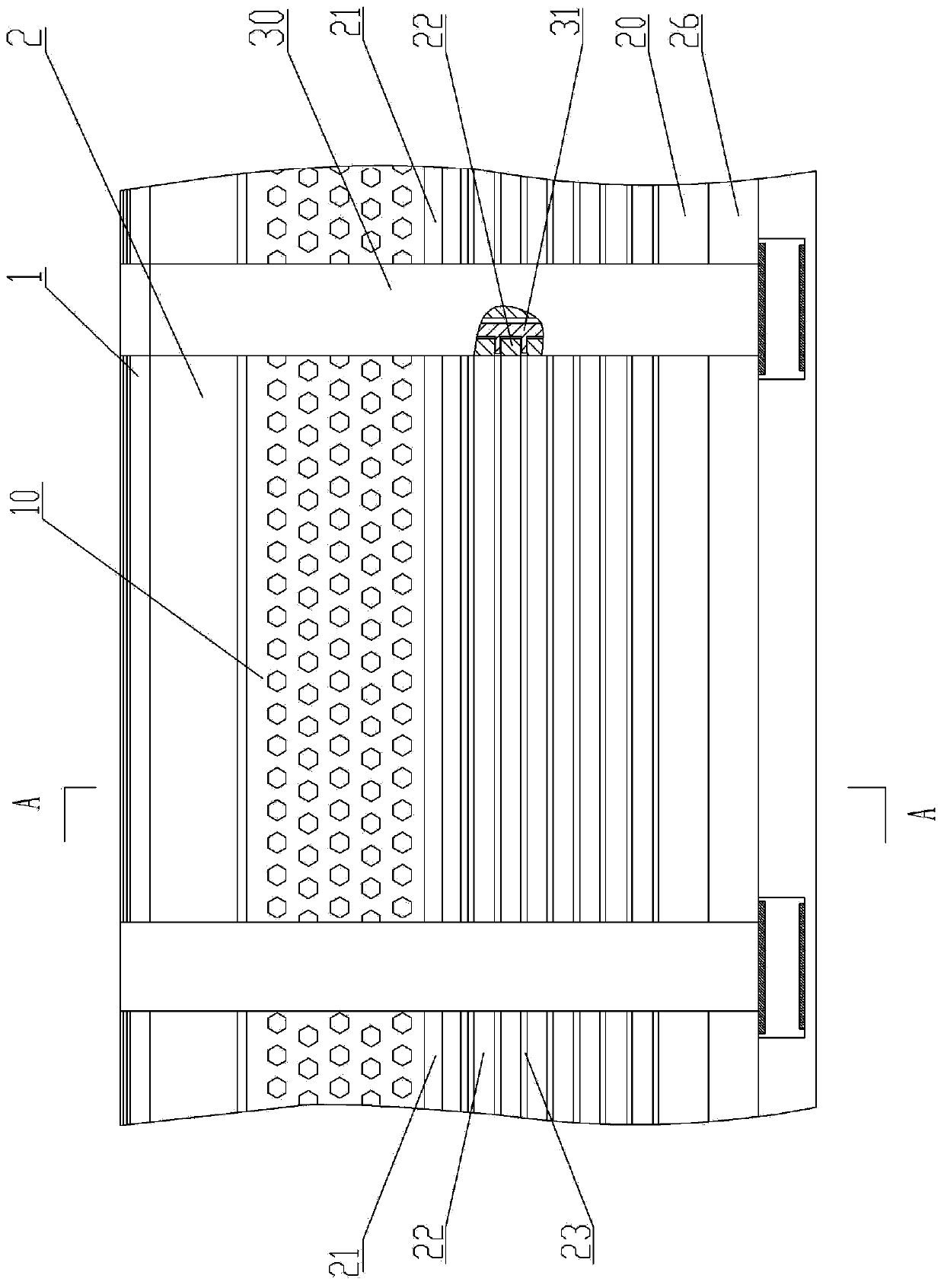

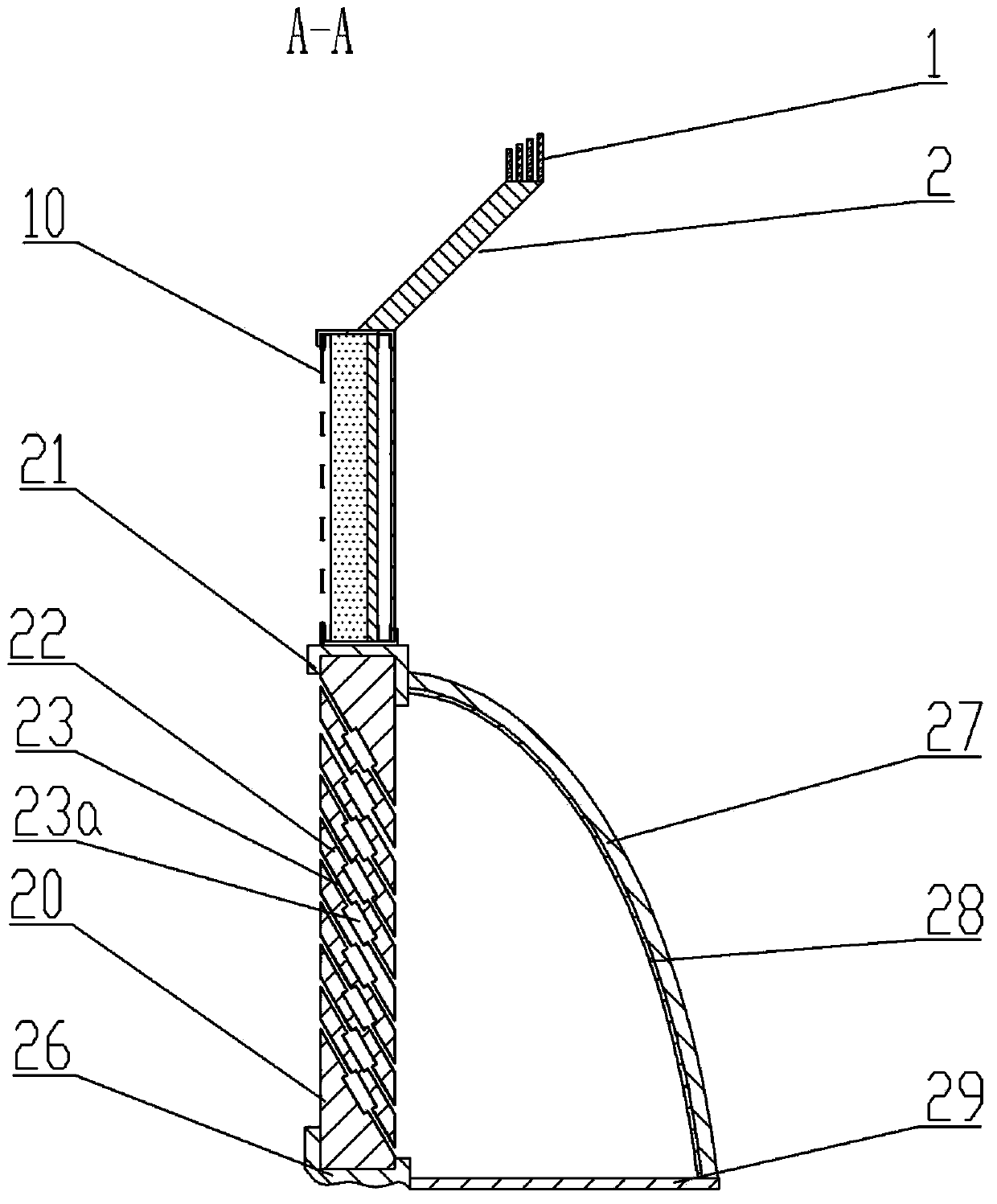

[0015] like figure 1 , 2 As shown, the specific embodiment of the present invention is a high-speed railway composite load-reducing sound barrier, including an H-shaped column 30, an upper unit plate 10 and a lower unit plate 20 inserted between the H-shaped columns 30, and is characterized in that: The composition of the lower unit plate 20 is: a plurality of inclined sloping plates 22 are fitted and fixed on the mullion 31 at equal intervals, and the middle of the cavity 23 on the opposite surface of any two slanting plates is slotted to form a larger space. Acoustic cavity 23a, the upper end and lower end of mullion 31 are respectively connected with upper frame 21 and lower frame 26 to form a fixed frame; the fixed frame is inserted into the lower part of H-shaped column 30; the outer side of upper frame 21 is connected with a parabolic skirt 27 opening downward The lower part of the skirt board 27 is connected with the lower frame 26 through a plurality of cross bars 29;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com