Muffler unit for saddle-ride type vehicle

A riding-type vehicle and muffler technology, which is applied in the direction of mufflers, exhaust devices, bicycle accessories, etc., can solve the problems of low operating efficiency and difficult installation operations, and achieve easy installation operations, reduce the number of parts, and improve workability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

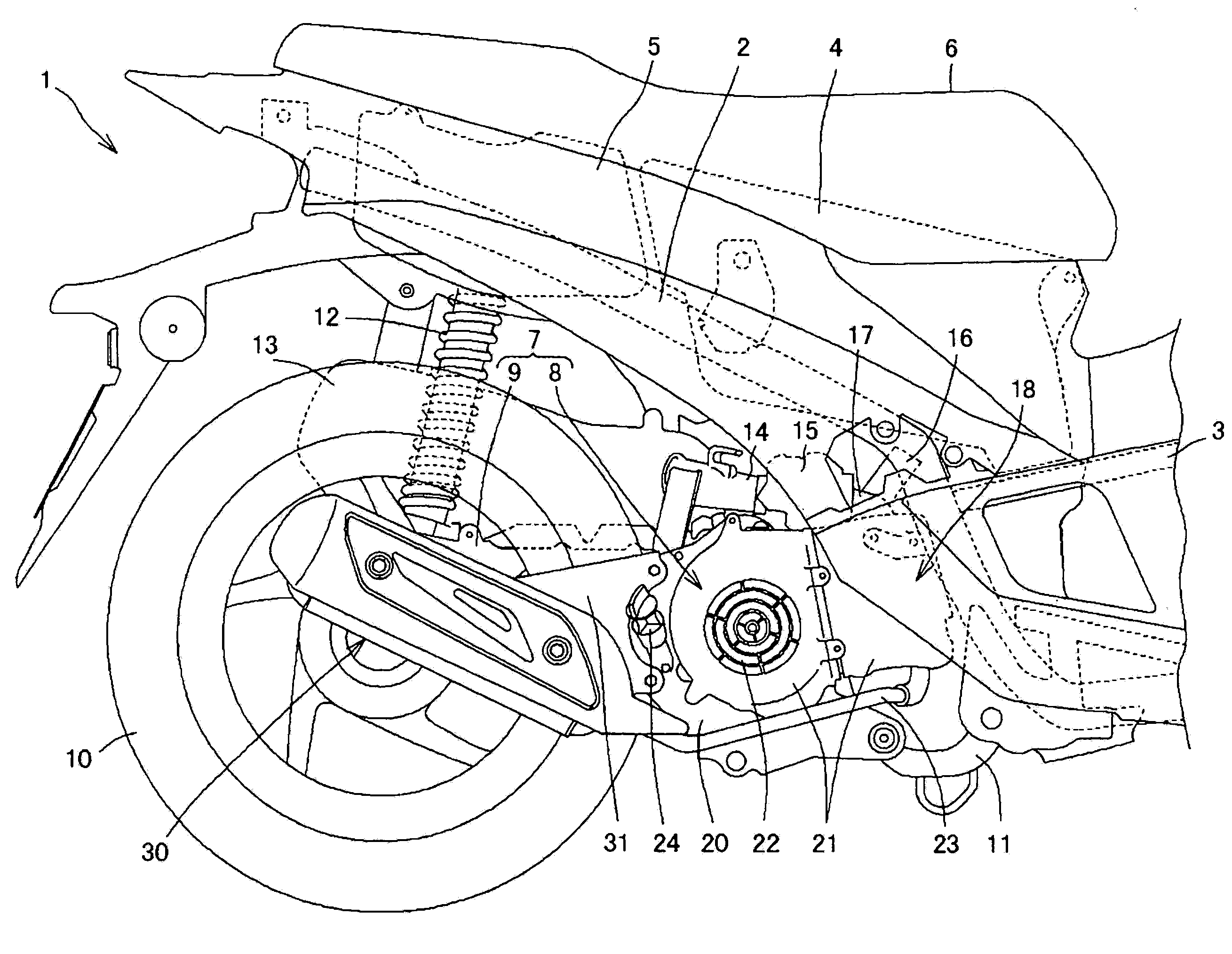

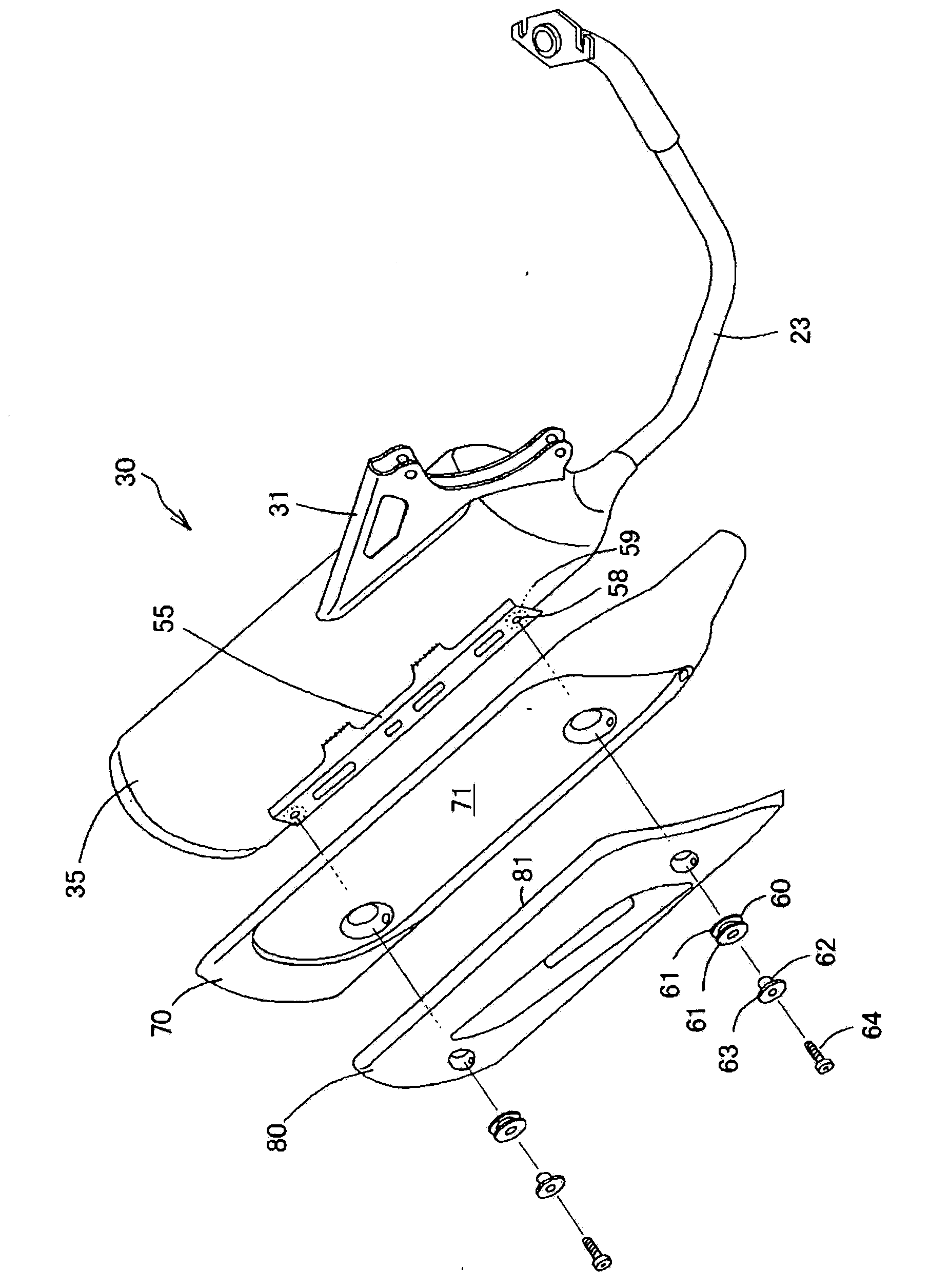

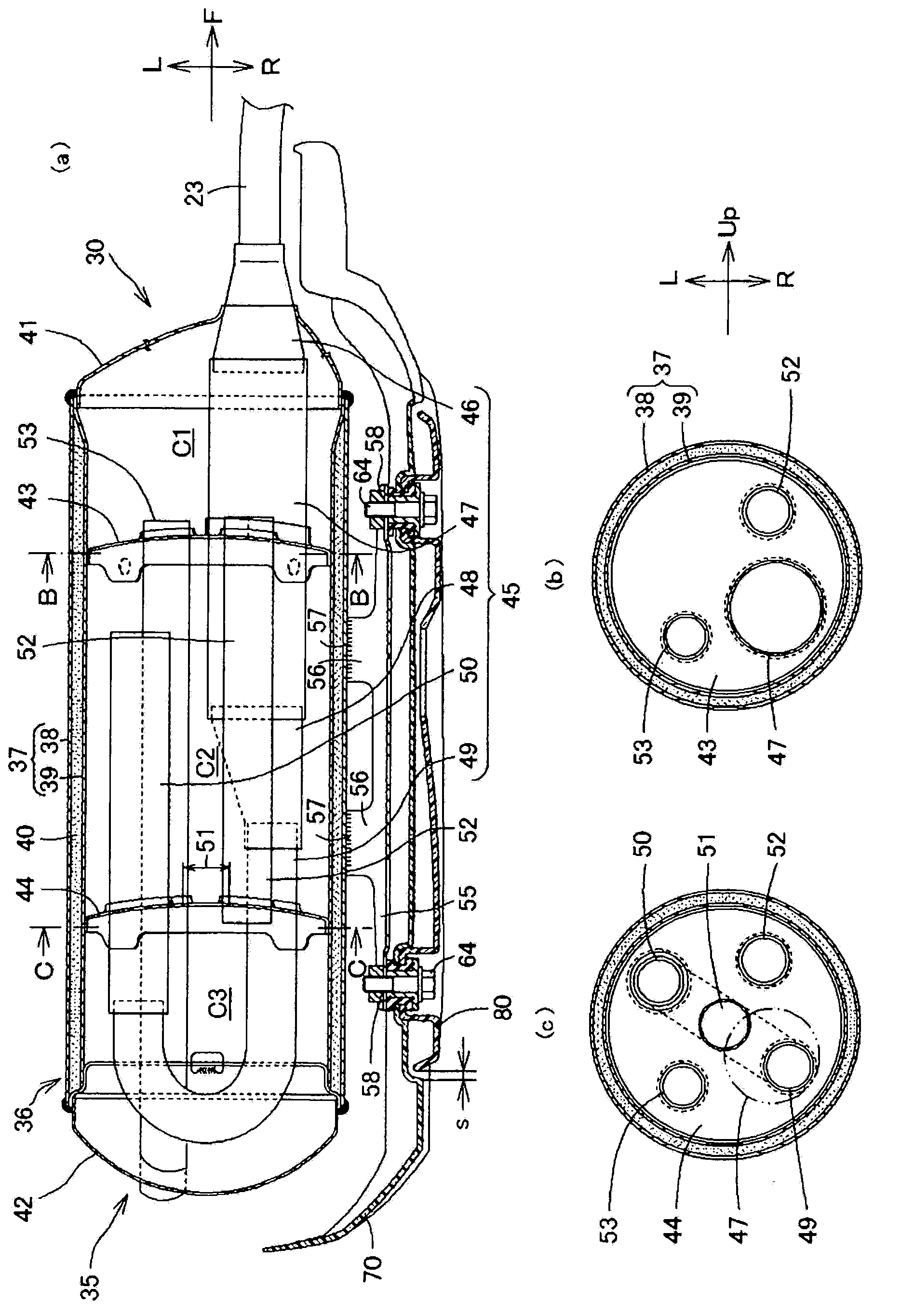

[0056] figure 1 It is a right side view of the rear part of the motorcycle 1 which concerns on one Embodiment of this invention. The frame of this vehicle is composed of a main frame 2 and a sub-frame 3. The main frame 2 hangs down from the head pipe that can steerably support the front fork and extends rearward. The front fork is used to pivotally support the front wheel, and the sub-frame 3 is mounted on the rear upper part of the above-mentioned head pipe and the above-mentioned main frame 2 . The said main frame 2 supports the helmet storage part 4, the fuel tank 5, and the seat cushion 6 for a vehicle by the upper part.

[0057] The power unit 7 of the motorcycle 1 is an integrated power unit of an internal combustion engine 8 and a power transmission device 9 . The internal combustion engine 8 is a forced air-cooled one-cylinder internal combustion engine, and is located at the center in the left-right direction of the vehicle. The power transmission device 9 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com