Buffer

A buffer and impact force technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of unstable buffering process of heavy equipment, large axial installation volume, buffer rebound bumps, etc. To achieve the effect of highlighting the substantive features, solving the large axial volume and increasing the buffer force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

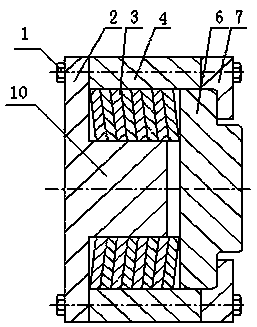

[0027] Depend on figure 1 As shown, a buffer of the present invention includes a base 2 for fixing the buffer and a block 6 for bearing impact force; the middle part of the base 2 has a mandrel 10, and the base 2 has a mandrel An elastic element is provided between one side of 10 and the stopper 6, and an elastic element support sleeve 4 is arranged on the periphery of the elastic element, and an elastic element support sleeve 4 is provided at the connection between the elastic element support sleeve 4 and the stop block 6 for limiting the stopper. The end cover 7 of the block 6, the end cover 7 and the elastic element support sleeve 4 are fixed on the base 2 by bolts 1 .

[0028] Wherein, in the above embodiments, the elastic element is fixedly connected with the stopper 6 .

[0029] Wherein, in the above-mentioned embodiment, the elastic element is a Belleville spring set 3, the free height of the Belleville spring set 3 is greater than the height of the mandrel 10, and one...

Embodiment approach 2

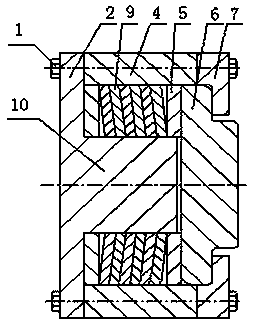

[0034] Depend on figure 2 and image 3 As shown, the difference from Embodiment 1 is that the elastic element in this embodiment includes a Belleville spring set 9 and backing plates 5 fixed at both ends of the Belleville spring set 9, the Belleville spring set 9 and two backing plates The sum of the free heights of 5 is greater than the height of the mandrel 10 , and the backing plate 5 at one end of the Belleville spring group 9 adjacent to the stop 6 is fixed on the stop 6 . The butterfly spring group 9 is fixed on the stopper 6 through the backing plate 5, and forms a stressed living body with the stopper 6, which improves the stability of the buffering process of the buffer, thereby increasing the service life of the buffer.

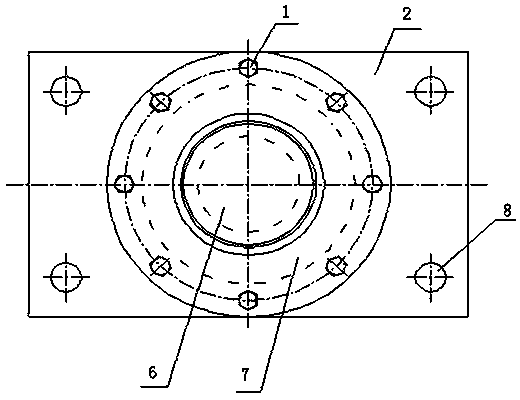

[0035] In summary, when the present invention is used, the buffer is fixed to the corresponding position of the equipment body through the four bolt holes 8 on the base 2. When the equipment body is impacted, the stopper 6 directly bears all the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com