Plastic-coated hose easy to pull and resistant to abrasion

A technology for plastic-coated hoses and hoses, which is applied in the direction of hoses, pipes, and pipeline protection. No problems such as high, to achieve the effect of increased anti-wear allowance, long service life and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

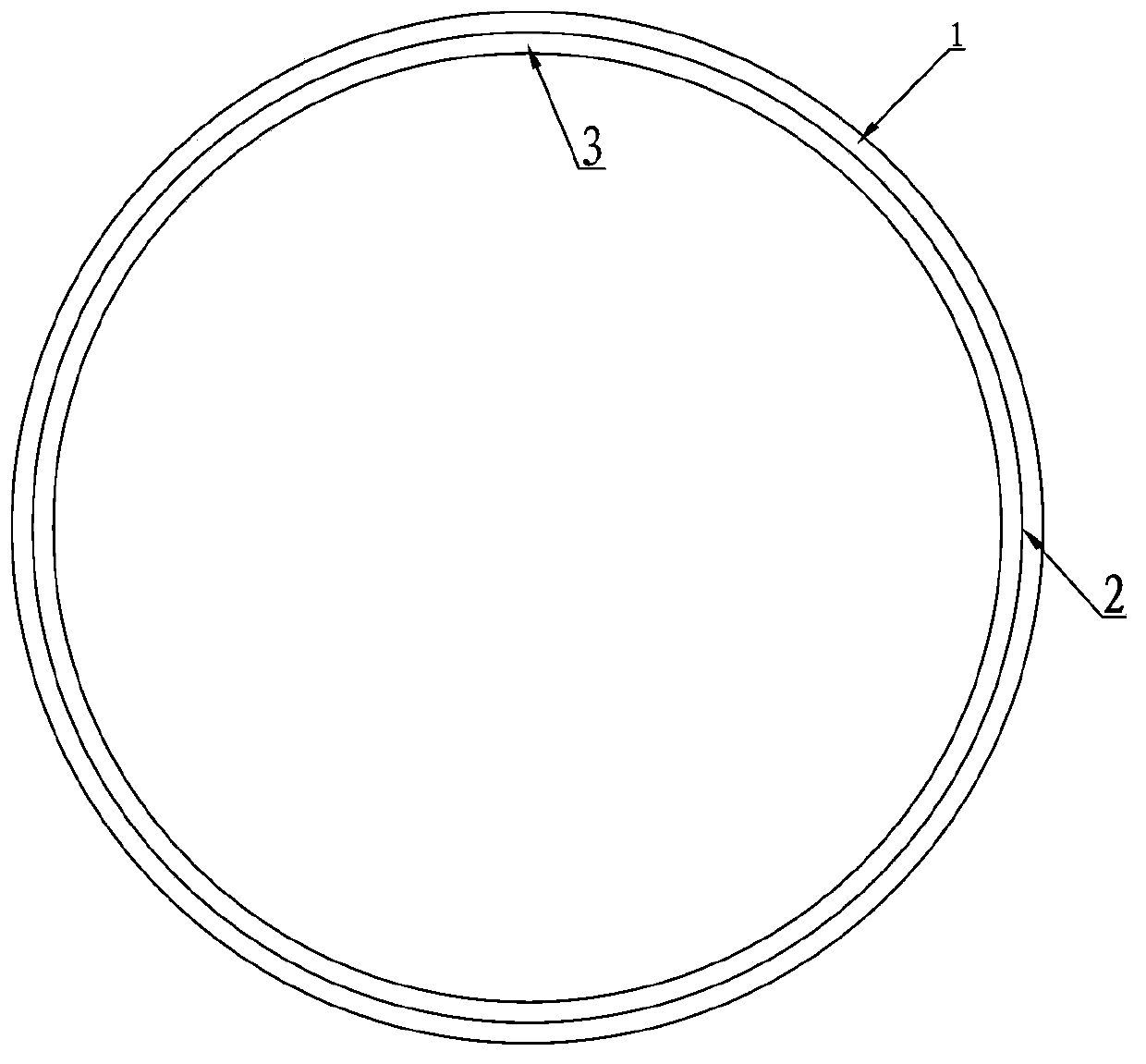

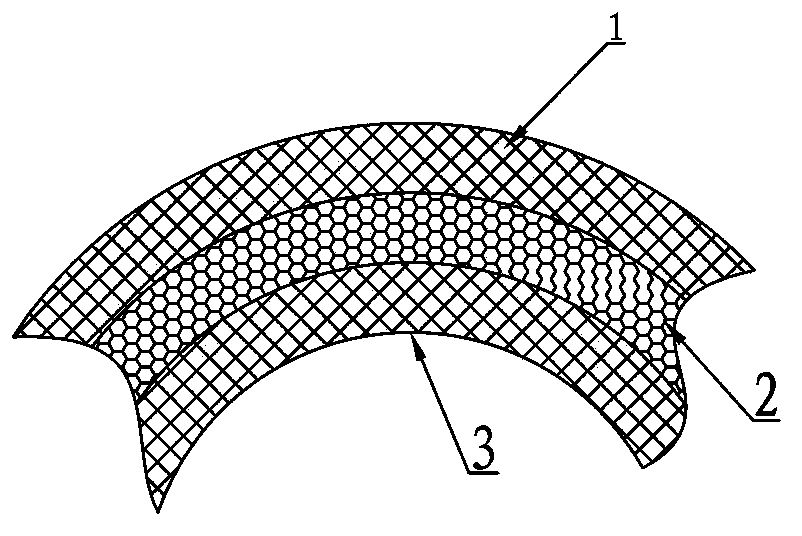

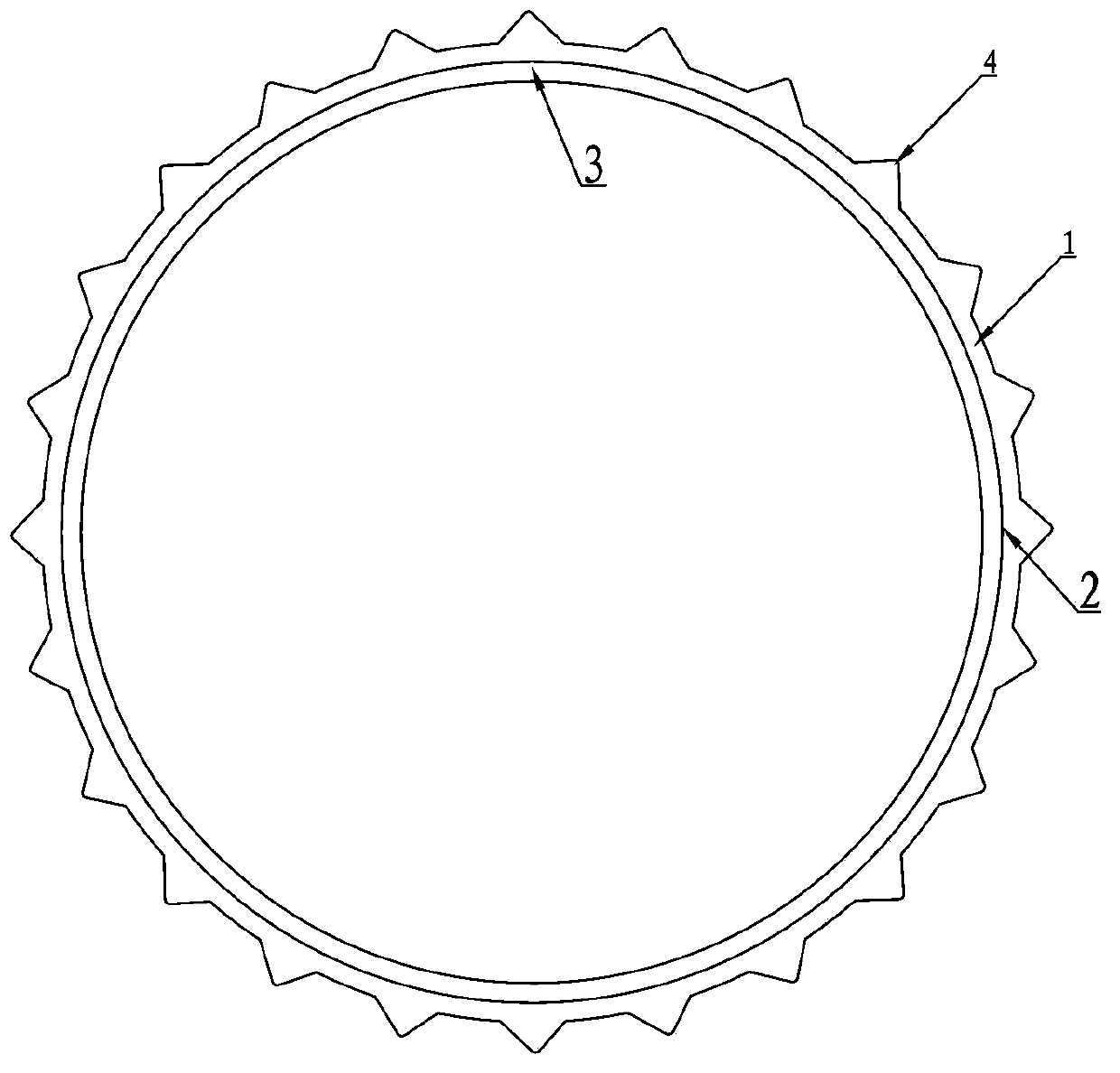

[0027] An easy-to-pull wear-resistant plastic-coated hose, comprising an outer plastic layer 1, a woven bag 2, an inner plastic layer 3 and a wear-resistant convex body 4, the woven bag 2 is arranged in the middle of the outer plastic layer 1 and the inner plastic layer 2, The outer surface of the outer plastic layer 1 is provided with wear-resistant protrusions 4, the wear-resistant protrusions 4 are strip-shaped protrusions, the strip-shaped protrusions are parallel to the axis of the plastic-coated hose, and are evenly distributed along the circumference of the pipe body , the protruding height of the wear-resistant convex body 4 is 0.5-3 mm, the angle between two adjacent strip-shaped convex bodies is 1°-15°, and the cross-sectional shape of the wear-resistant convex body 4 is triangular.

[0028] Embodiments of the present invention are many, and the surface body is in the cross-sectional shape of the wear-resistant convex body 4, and the cross-sectional shape of the wear-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com