Production method of integrated multilayer lighting set

A technology for a lighting device and a manufacturing method, which is applied to the parts of the lighting device, the lighting device, and the cooling/heating device of the lighting device, etc., can solve the problem of complicated manufacturing steps, less heat dissipation than metal materials, and heat dissipation that affects the service life of light-emitting diodes Luminous efficacy and other issues to achieve the effect of protection from deterioration and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following describes the embodiments of the present invention in more detail in conjunction with the drawings and component symbols, so that those skilled in the art can implement them after studying this specification.

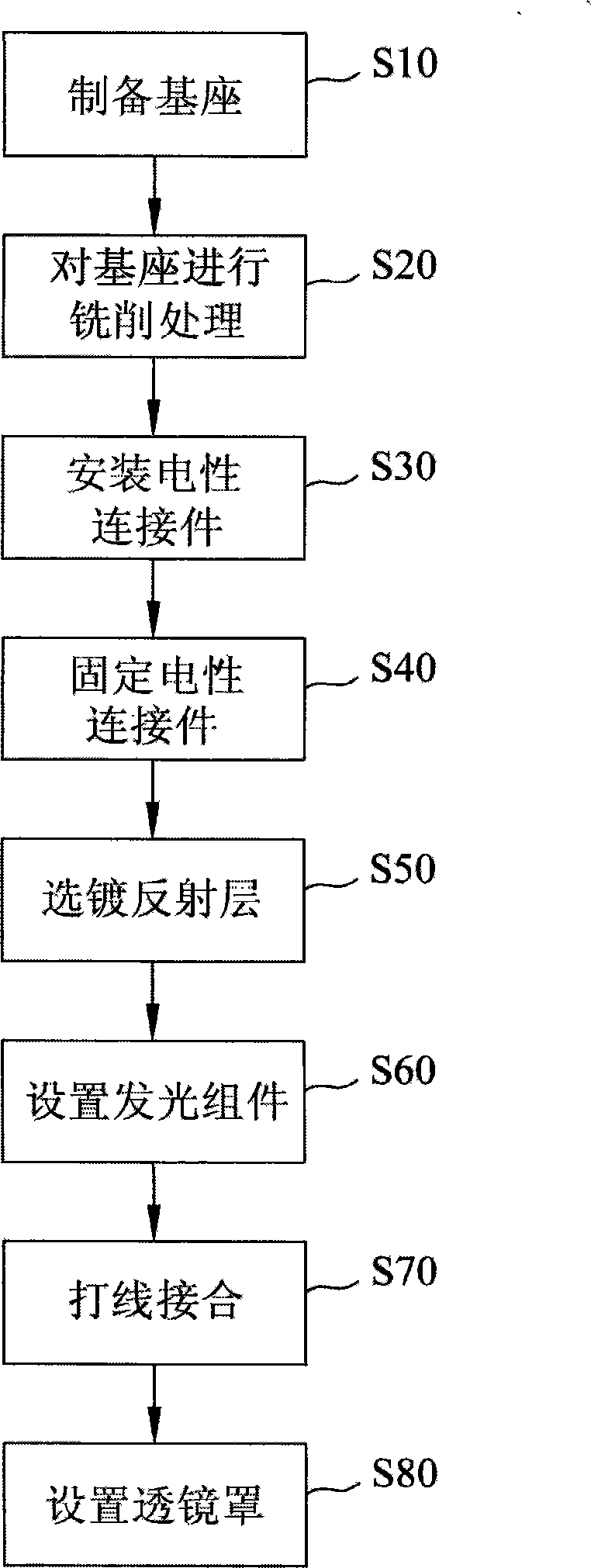

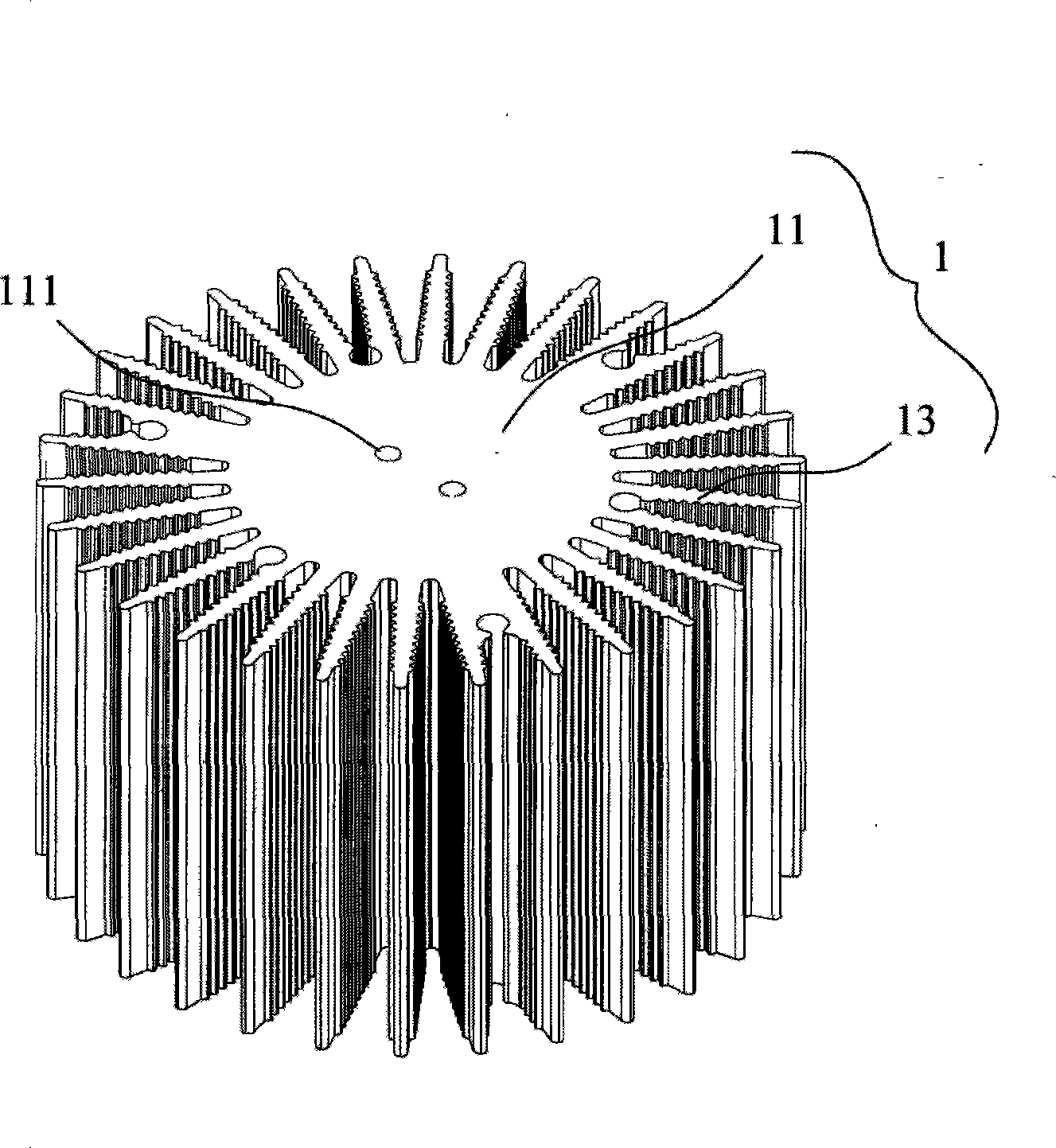

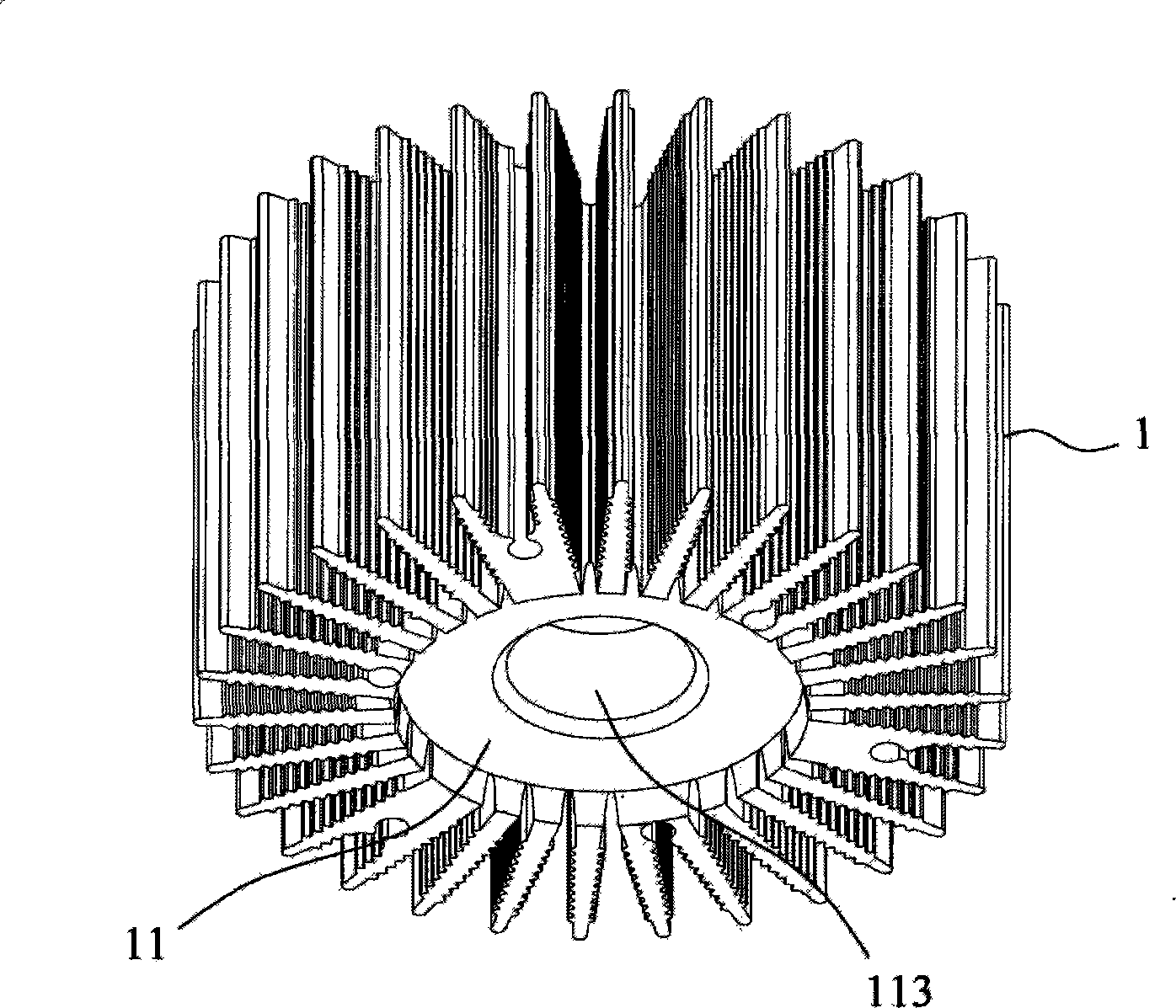

[0045] reference figure 1 , figure 1 It is a flow chart of the manufacturing method of the integrated multi-layer lighting device of the present invention, and cooperates with figure 2 , figure 2 It is a schematic view of the base of the manufacturing method of the integrated multi-layer lighting device of the present invention. Such as figure 1 As shown in step S10, the base 1 is first prepared, and the prepared base 1 includes a central body 11 and heat dissipation fins 13. The heat dissipation fins 13 are formed by extending outward in a radial arrangement, and the heat dissipation fins 13 There is a gap between them, and the surfaces of the two sides of the radiating fin 13 are undulating, such as figure 2 Shown. Among them, the center of the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com