Full-glass vacuum heat collection element changing vacuum degree for stagnation protection

A technology of vacuum heat collection and vacuum degree, which is applied to solar collectors, solar collectors using working fluids, heating devices, etc. It can solve the problems of high vapor pressure of the working fluid in the heat pipe and achieve a large anti-air exposure margin. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

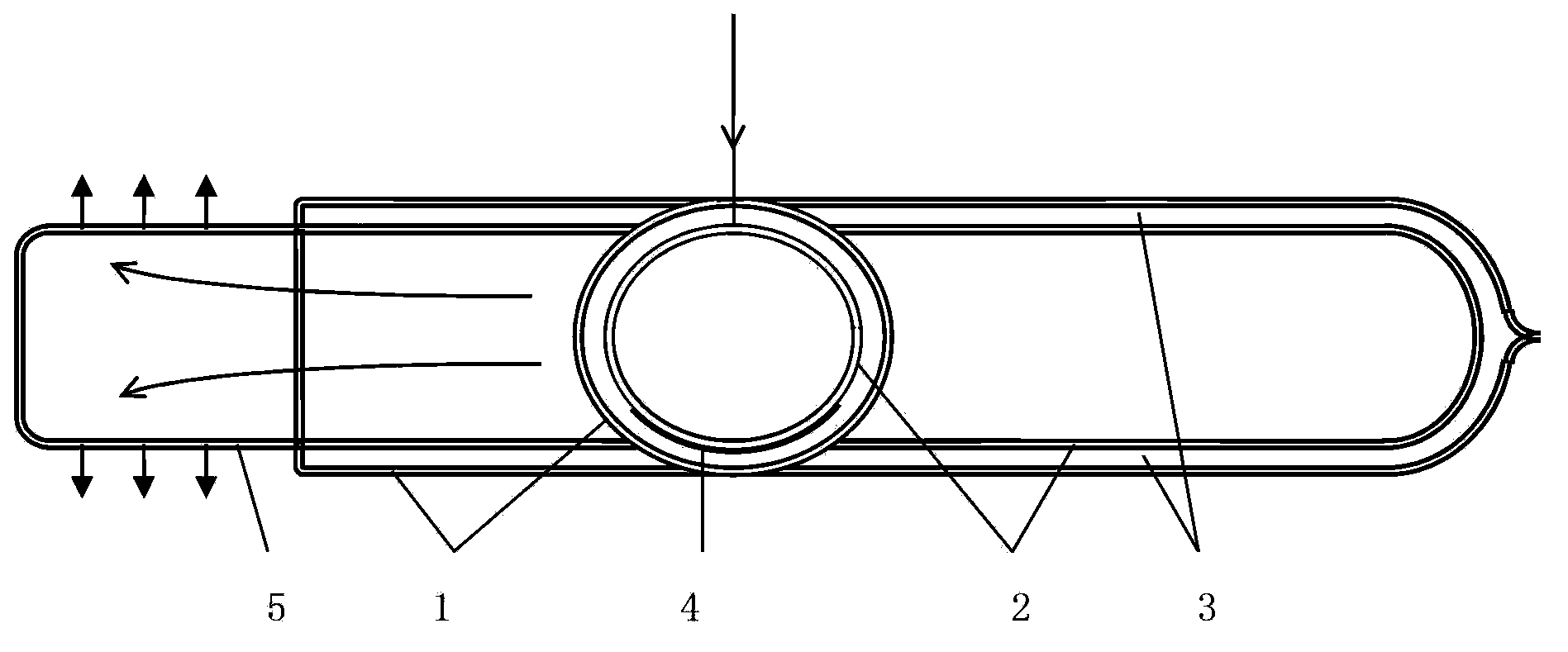

[0013] figure 1 An example of the present invention is given.

[0014] figure 1 In the process, the cover glass tube 1 and the inner glass tube 2 are concentrically sealed to form a jacket, and the interlayer of the jacket is evacuated to form a vacuum heat insulation layer 3, and a variable vacuum degree air protection device is made. Glass vacuum collector element. A selective absorption film is deposited on the inner glass tube 2 . A piece of activated carbon fiber adsorption material 4 with a length of about 200 mm is connected to the non-light-facing surface of the inner glass tube 2 at an approximately 140-degree circumferential angle region with a low thermal resistance of a steel wire circlip. The inner glass tube 2 extends outward for a section at the melting sealing place and is sealed, and the inside of the inner glass tube 2 is evacuated and filled with working fluid and sealed to form a heat pipe.

[0015] figure 1 The working principle of the embodiment: sun...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap