Method for manufacturing temperature-resistance and wear-resisting three-layer insulated wire

A three-layer insulation and manufacturing method technology, applied in the direction of cable/conductor manufacturing, conductor/cable insulation, electrical components, etc., can solve the problem that the heat resistance temperature cannot meet the safety, reliability, and stability performance, and achieve safety performance and use Improved life and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

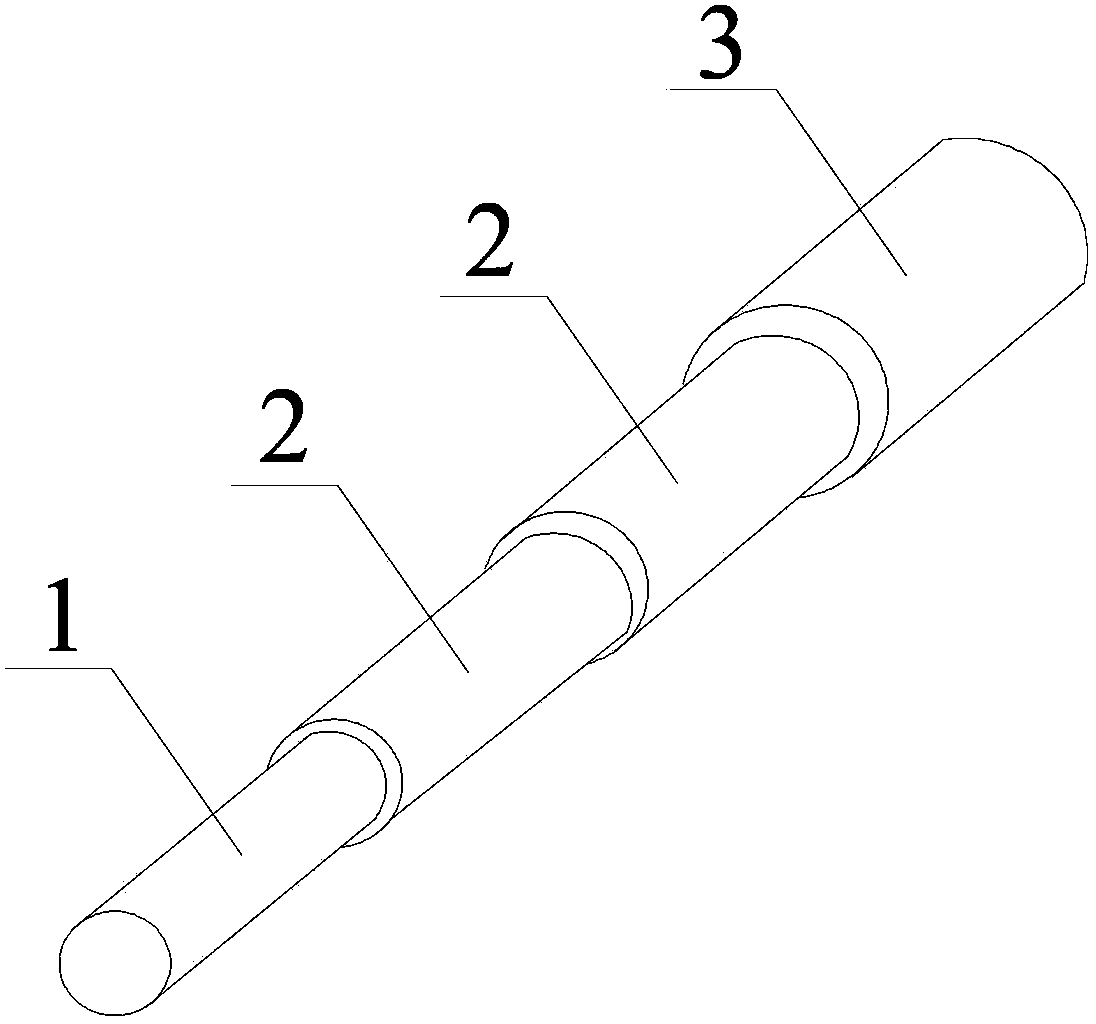

[0017] A temperature-resistant and wear-resistant three-layer insulated wire, its structure is as follows figure 1 As shown, it includes an inner core 1 composed of a copper conductor, two layers of modified polyester insulating layers 2, and one layer of polyamide resin layer 3.

[0018] The manufacturing method of the temperature-resistant and wear-resistant three-layer insulated wire includes the following steps: combining copper conductors into the inner core 1 of the insulated wire, and then using a single-screw extruder to sequentially extrude two layers of modified polyester insulating layers 2 onto the copper conductor Finally, the polyamide resin layer 3 is extruded on the outside of the two modified polyester insulating layers 2 using a single-screw extruder.

[0019] Wherein, the modified polyester insulating layer is composed of polyester resin added with superfine talcum powder and surface modifier, the addition amount of superfine talcum powder is 1wt% of the pol...

Embodiment 2

[0034] A method for manufacturing a temperature-resistant and wear-resistant three-layer insulated wire, comprising the following steps: combining copper conductors into the inner core of the insulated wire, and then using a single-screw extruder to sequentially extrude two layers of modified polyester insulating layers on the copper On the outside of the conductor, finally use a single-screw extruder to extrude the polyamide resin layer on the outside of the two modified polyester insulating layers of the bun.

[0035] Wherein, the modified polyester insulating layer is composed of polyester resin added with superfine talcum powder or nano-soil and surface modifier, and the addition amount of super-fine talcum powder or nano-soil is 1wt% of polyester resin, and the surface modification The addition amount of agent is 1wt% of polyester resin. The surface modifier used was glycidyl methacrylate and the polyester was polyethylene terephthalate.

Embodiment 3

[0037] A method for manufacturing a temperature-resistant and wear-resistant three-layer insulated wire, comprising the following steps: combining copper conductors into the inner core of the insulated wire, and then using a single-screw extruder to sequentially extrude two layers of modified polyester insulating layers on the copper On the outside of the conductor, finally use a single-screw extruder to extrude the polyamide resin layer on the outside of the two modified polyester insulating layers.

[0038] Wherein, the modified polyester insulating layer is composed of polyester resin added with superfine talcum powder or nano-soil and surface modifier. The addition of superfine talcum powder or nano soil is 5wt% of polyester resin, the addition of surface modifier is 2wt% of polyester resin, and the surface modifier used is glycidyl methacrylate and methacrylic acid Terpolymer of glycidyl ester and ethylene-acrylic acid ester, polyester package is a blend of polybutylene t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com