Substrate, light-emitting device, and illumination device

A technology for substrates and light-emitting elements, applied in the fields of light-emitting devices, lighting devices, and substrates, can solve the problems of increased wiring resistance, low resistance, difficult metal wiring thickness, etc., and achieve the effect of suppressing voltage rise and realizing insulation distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

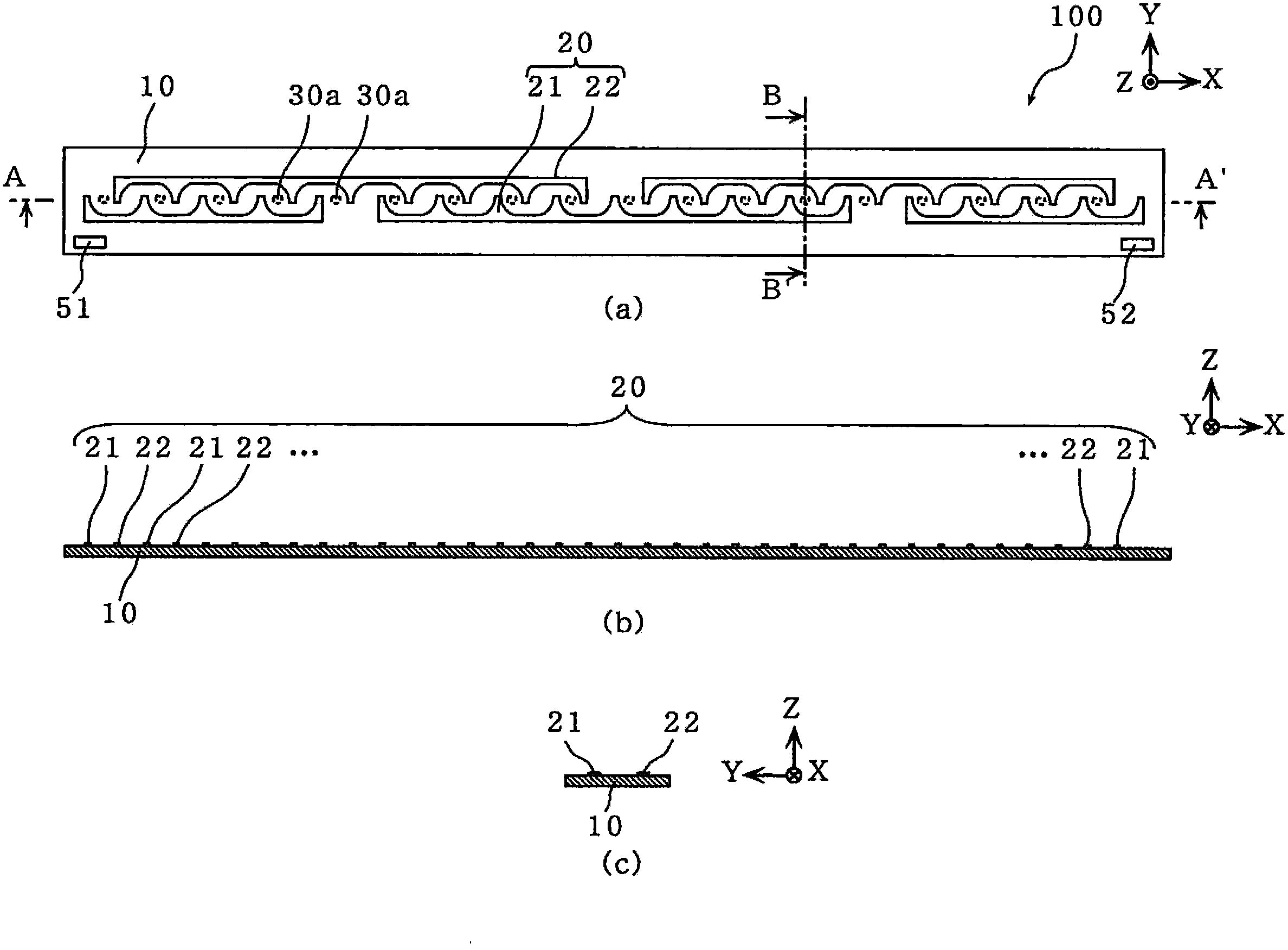

[0061] First, use figure 1 The configuration of the mounting substrate 100 according to the first embodiment of the present invention will be described. figure 1 (a) is a plan view of the mounting substrate according to Embodiment 1 of the present invention, figure 1 (b) is a cross-sectional view of the mounting substrate cut along the line AA' of (a) (substrate longitudinal cross-section), figure 1 (c) is a cross-sectional view (substrate short-direction cross-section) of the mounting substrate cut along line BB' of (a). Furthermore, the long direction of the substrate 10 is defined as the X-axis direction, the short direction of the substrate 10 as the direction perpendicular to the X-axis is defined as the Y-axis direction, and the direction perpendicular to the X-axis and the Y-axis is defined as a direction relative to The direction perpendicular to the principal surface of the substrate 10 is referred to as the Z-axis direction.

[0062] like figure 1 (a) to (c) show...

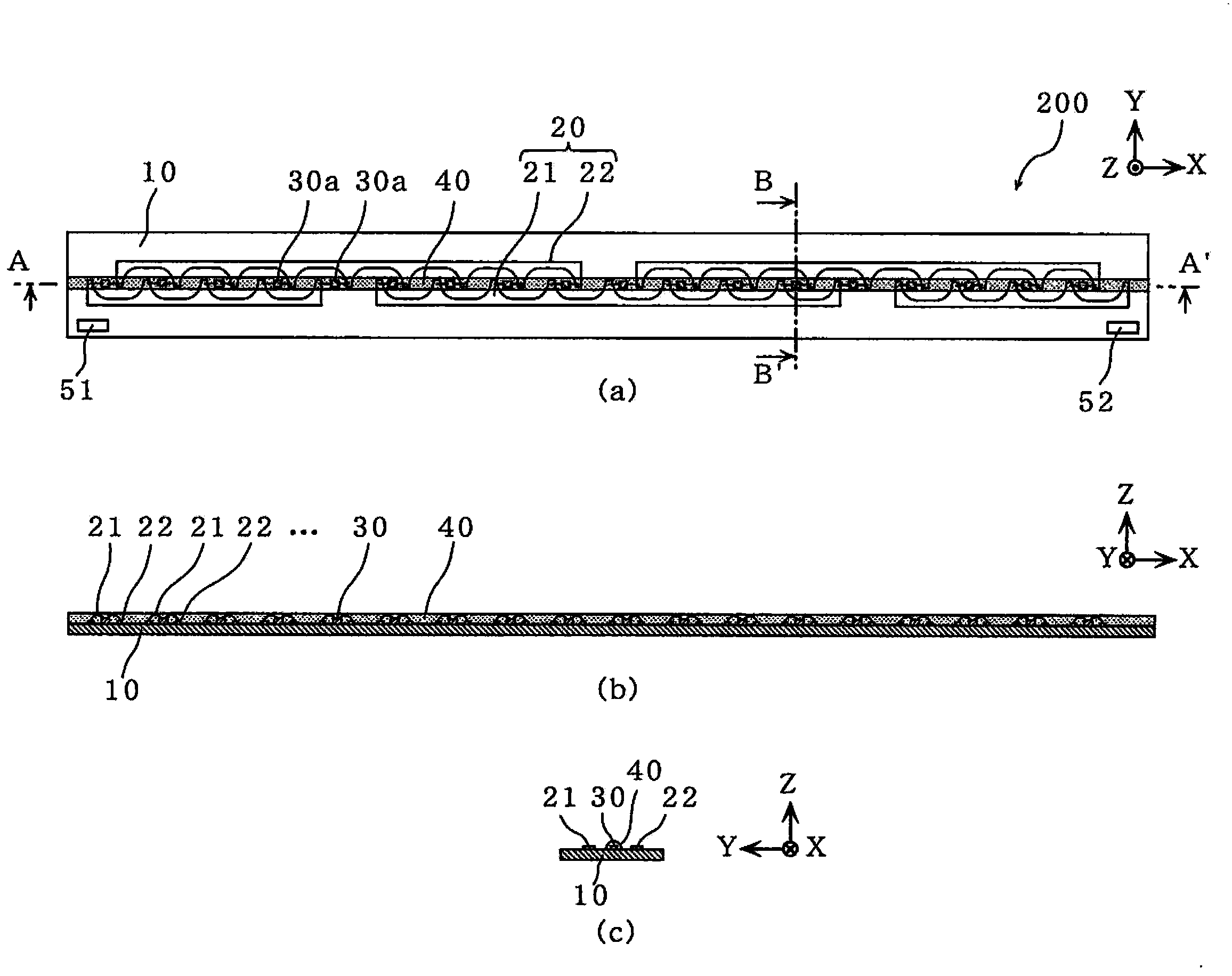

Embodiment 2

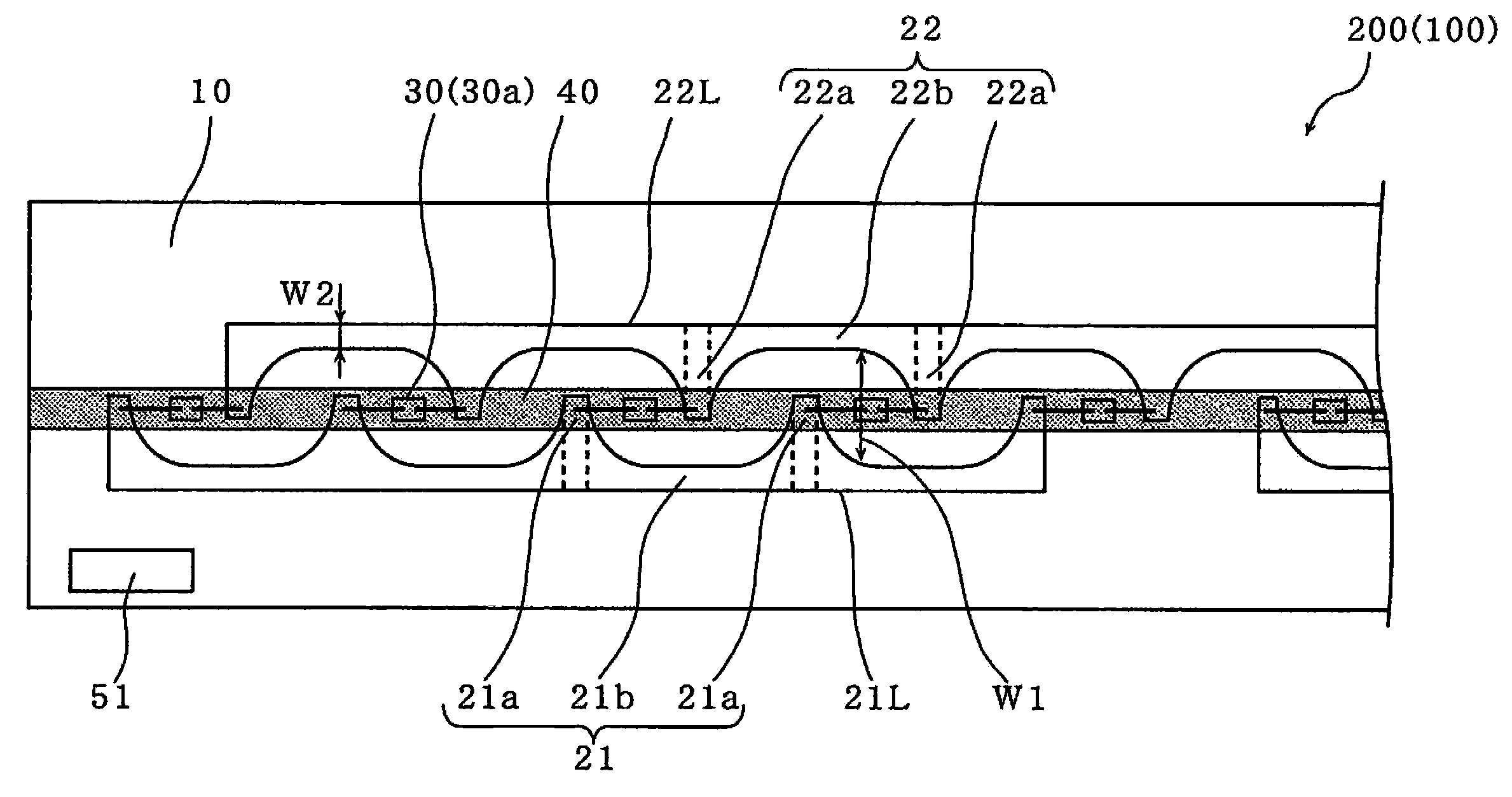

[0120] Next, use Figure 5 A mounting substrate 100X and a light emitting device according to Embodiment 2 of the present invention will be described. Figure 5 It is a partially enlarged view of a mounting substrate according to Embodiment 2 of the present invention.

[0121] Since the mounting substrate 100X and the light emitting device according to this embodiment have the same basic structure as the mounting substrate 100 and the light emitting device 200 according to the first embodiment, the following description will focus on the differences between the two. In addition, the same reference numerals are assigned to the same components of the present embodiment as in the first embodiment, and detailed descriptions are omitted or simplified. Furthermore, in the light-emitting device of this embodiment, using Figure 5 The mounting substrate 100X is shown.

[0122] In the mounting substrate 100X and the light-emitting device according to this embodiment, as in the first...

Embodiment 3

[0136] Next, use Image 6 A mounting substrate 100Y and a light emitting device 200Y according to Embodiment 3 of the present invention will be described. Image 6 (a) is a partially enlarged view of a mounting substrate according to Embodiment 3 of the present invention, Image 6 (b) is a partially enlarged view of a light emitting device according to Example 3 of the present invention.

[0137] Since the mounting substrate 100Y and the light emitting device 200Y according to the present embodiment have the same basic structure as the mounting substrate 100 and the light emitting device 200 according to the first embodiment, the following description will focus on their differences. In addition, the same reference numerals are assigned to the same components of the present embodiment as in the first embodiment, and detailed descriptions are omitted or simplified.

[0138] exist figure 1 In the mounting substrate 100 of the shown embodiment 1, the LED mounting positions 30a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com