Chinese wolfberry picking machine

A picking machine and wolfberry technology, applied to picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of easily damaged fruits, limited efficiency, and difficult fruit picking, so as to improve picking efficiency and high picking rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

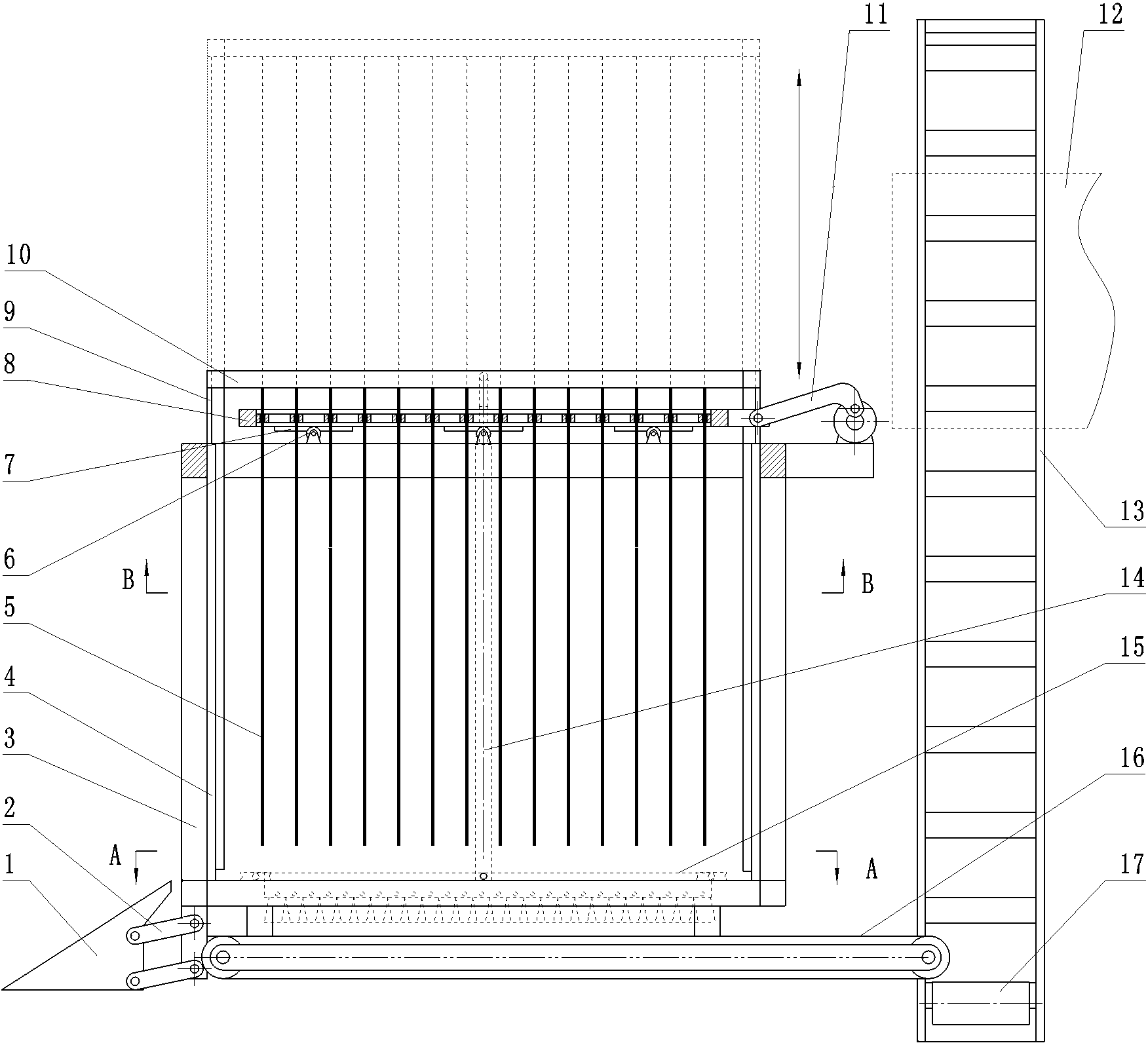

[0037] Example 1: refer to Figure 1 to Figure 5 , is a structural schematic diagram of Embodiment 1 of the present invention. This embodiment is self-propelled, including a power locomotive 18, a transmission mechanism and a main frame body 3. A group of main frame bodies 3 are respectively provided on both sides of the power locomotive 18, which can simultaneously Two trees for picking operations.

[0038] The main frame body 3 is a door-like frame with a longitudinal channel at the bottom, and the front part of the longitudinal channel of the main frame body 3 is provided with a grain raising device 1, and a four The linkage mechanism 2 is connected.

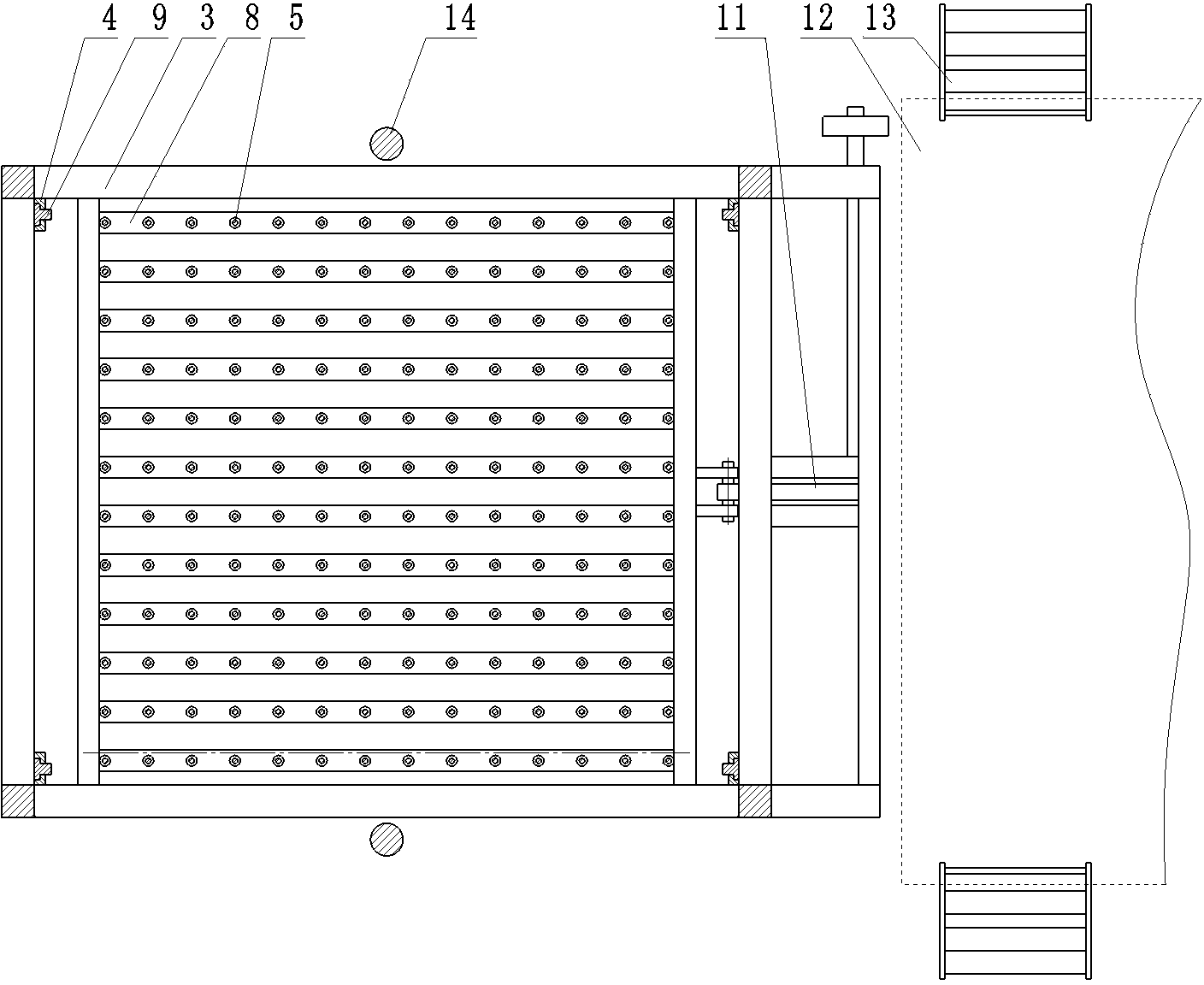

[0039] The main frame body 3 is provided with a picking frame, which includes a lifting frame 10 that can be lifted up and down. A lifting mechanism 14 is arranged between the main frame bodies 3. The lifting mechanism 14 of the present embodiment is a hydraulic lifting mechanism, and the lifting frame 10 is provided with...

Embodiment 2

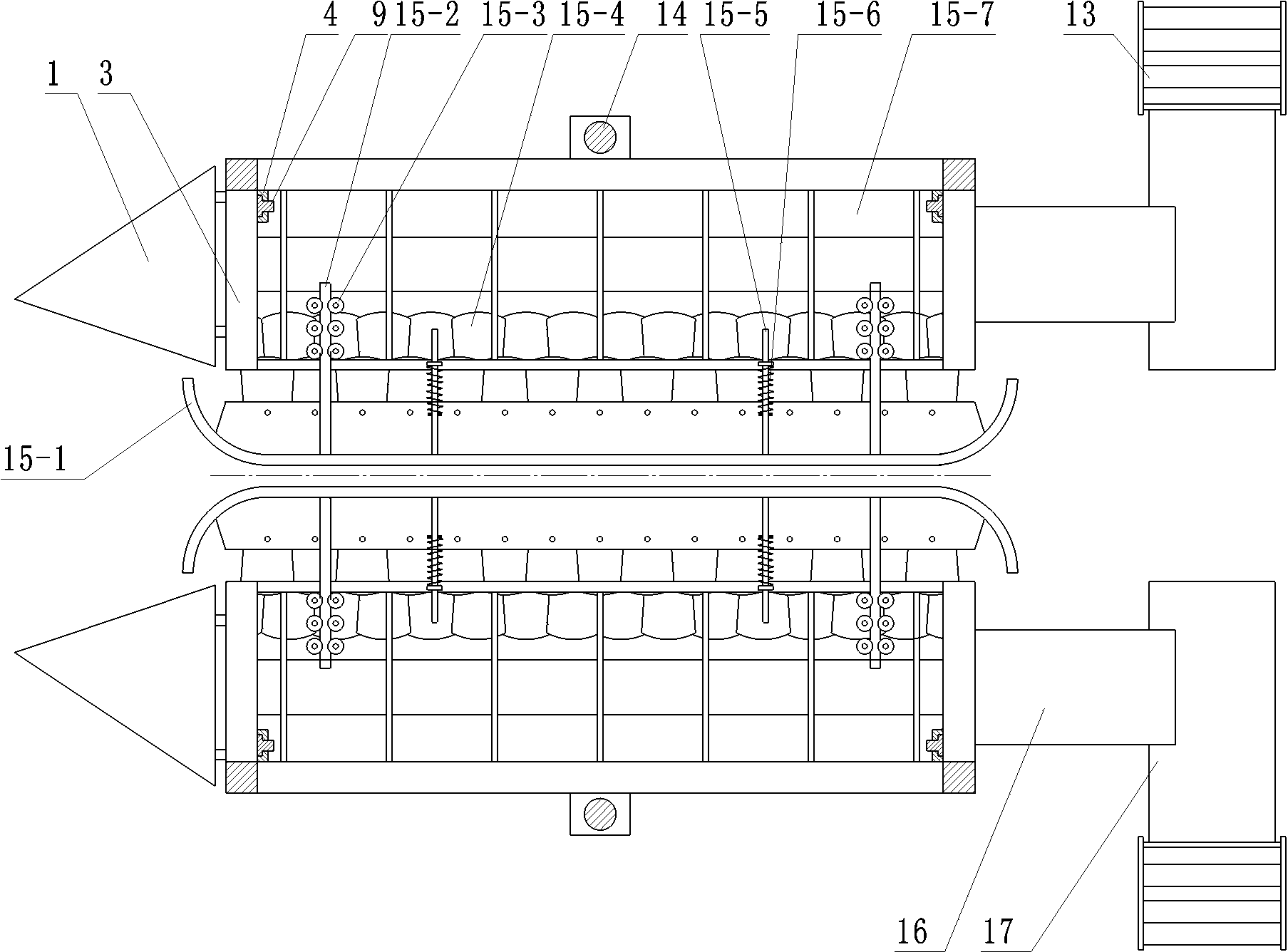

[0045] Example 2: refer to Figure 6 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the main difference of this embodiment is that: the guide mechanism 15-3 of the passage closer of the wolfberry collection mechanism is a guide groove, and the transverse guide rod 15-2 is A cylindrical open rod, the guide groove is a circular tube, and the transverse guide rod 15-2 is arranged in the guide groove.

[0046] Of course, the guide groove can also be in other forms, such as a rectangular cross-section, a dovetail shape, etc., which will not be repeated here.

Embodiment 3

[0047] Example 3: refer to Figure 6 , is a schematic structural diagram of Embodiment 3 of the present invention. Compared with Embodiment 2, the main difference of this embodiment is that the rollers 6 are arranged on the cradle 8, and the limit blocks 7 are arranged on the main frame 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com