Soybean cutting sheller

A dehulling machine and soybean technology, applied in the fields of application, food processing, food science, etc., can solve the problems of high flour content in soybean meal, high skin content in soybean meal, poor peeling effect, etc., and reduce the content of flour and soybean skin in the skin Low, bean-intact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

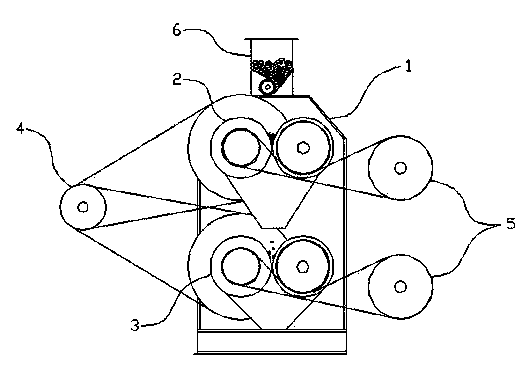

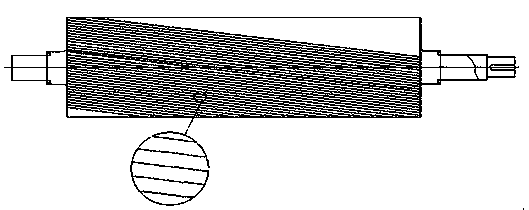

[0023] In order to obtain an ideal peeling effect, the distance between the two rollers of the cutting roller 2 can be properly adjusted according to the particle size of the raw material, so as to cut the whole grain of the raw material as the criterion. At the same time, most of the bean skins are also separated.

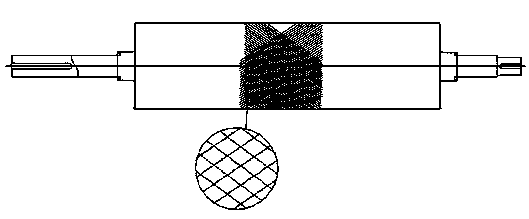

[0024] The distance between the peeling rollers 3 can be properly adjusted and adjusted according to the size of the watercress. The peaks of the two rollers are used to tie the watercress and the skin of the beans respectively, and the skin is pulled off the watercress with the speed difference of the two sticks.

[0025] The speed difference between each pair of rollers is 1:1.2 to 1:3, and the ideal speed difference is 1:1.4 to 1:2, which is the best.

[0026] The surface of the peeling roller 3 is provided with several tines formed by two intersecting helical grooves, and the tine gap is 5 mm. The angle between the two intersecting helical grooves is 30 degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com