Stirring machine

A mixer and mixing barrel technology, which is applied to mixer accessories, mixers, mixers with rotating containers, etc., can solve the problems that mixing cannot meet its requirements, and achieve precise temperature control, quality and efficiency improvement, and production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

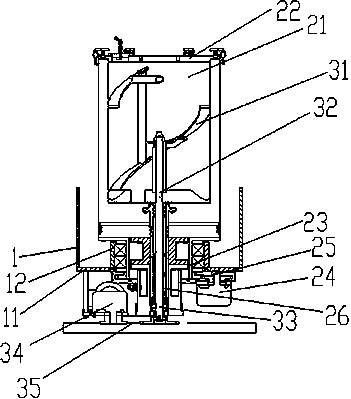

Embodiment 1

[0030] see figure 1 , as shown in the legend therein, a mixer includes a support 1, a mixing bucket mechanism and a mixing blade mechanism, the above mixing bucket mechanism includes a barrel body 21 for holding materials, a sealing barrel body 21 A barrel cover 22, a first rotating shaft 23 fixedly connected to the lower side of the barrel body 21, a first motor 24 for providing the first power, and a first gear for transmitting the first power to the first rotating shaft 23 Transmission system 25; above-mentioned stirring fan mechanism comprises a fan blade 31 for stirring above-mentioned material, the stirring shaft 32 of support fan blade 31, the second rotating shaft 33 that is fixedly connected to the lower end of stirring shaft 32, for providing A second motor 34 for the second power and a second gear transmission system 35 for transmitting the second power to the second rotating shaft 33; the support plate 11 is fixedly installed on the support plate 1; the collar 12 i...

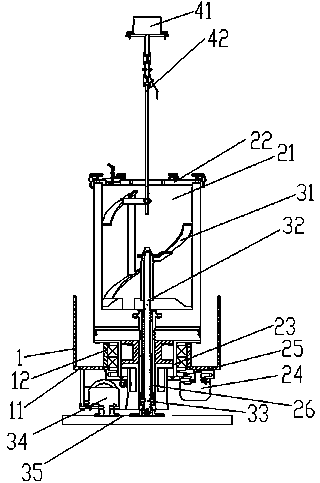

Embodiment 2

[0034] see figure 2 , as shown in the legend therein, the rest are the same as in the embodiment 1, the difference is that the above-mentioned mixing tank is also provided with an additive adding device, and the above-mentioned additive adding device includes an additive storage area 41 for storing additives and for adding to The additive feeding pipe 42 for feeding additives into the barrel body 21 ; the additive storage area 41 is arranged above the barrel body 21 ; the additive feeding pipe 42 connects the additive storage area 41 and the barrel body 21 .

[0035] During the stirring process, additives can be added to the barrel body 21 at any time, and the additives to be added are placed in the additive storage area 41, and the additives are passed into the material of the barrel body 21 through the additive feeding pipe 42, and fully mixed and stirred with the material , the amount and speed of addition of additives can be adjusted during this process.

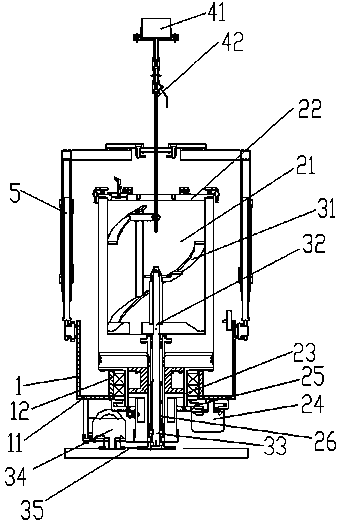

Embodiment 3

[0037] see image 3 , as shown in the legend therein, the rest are the same as the embodiment 2, the difference is that the above-mentioned mixing bucket is also provided with an oil cylinder 5 for opening or closing the bung 22, and one end of the oil cylinder 5 is arranged on the support 1; The other end of the oil cylinder 5 is connected to the bung 22 and lifts or presses the bung 22 on the bucket body 21 .

[0038] The oil cylinder 5 can press the bung 22 to seal the bucket body 21, and can automatically open the bung 22, which reduces the waste of manpower and improves the production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com