Double-supporting-arm coil collection device

A technology of supporting arms and collecting coils, which is used in bending workpieces, metal processing equipment, metal rolling, etc., can solve the problems of long coil falling distance, affecting transportation and bundling, and damaging the surface of wire rods, so as to facilitate maintenance and avoid The effect of loose roll and random roll, and the effect of reducing surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

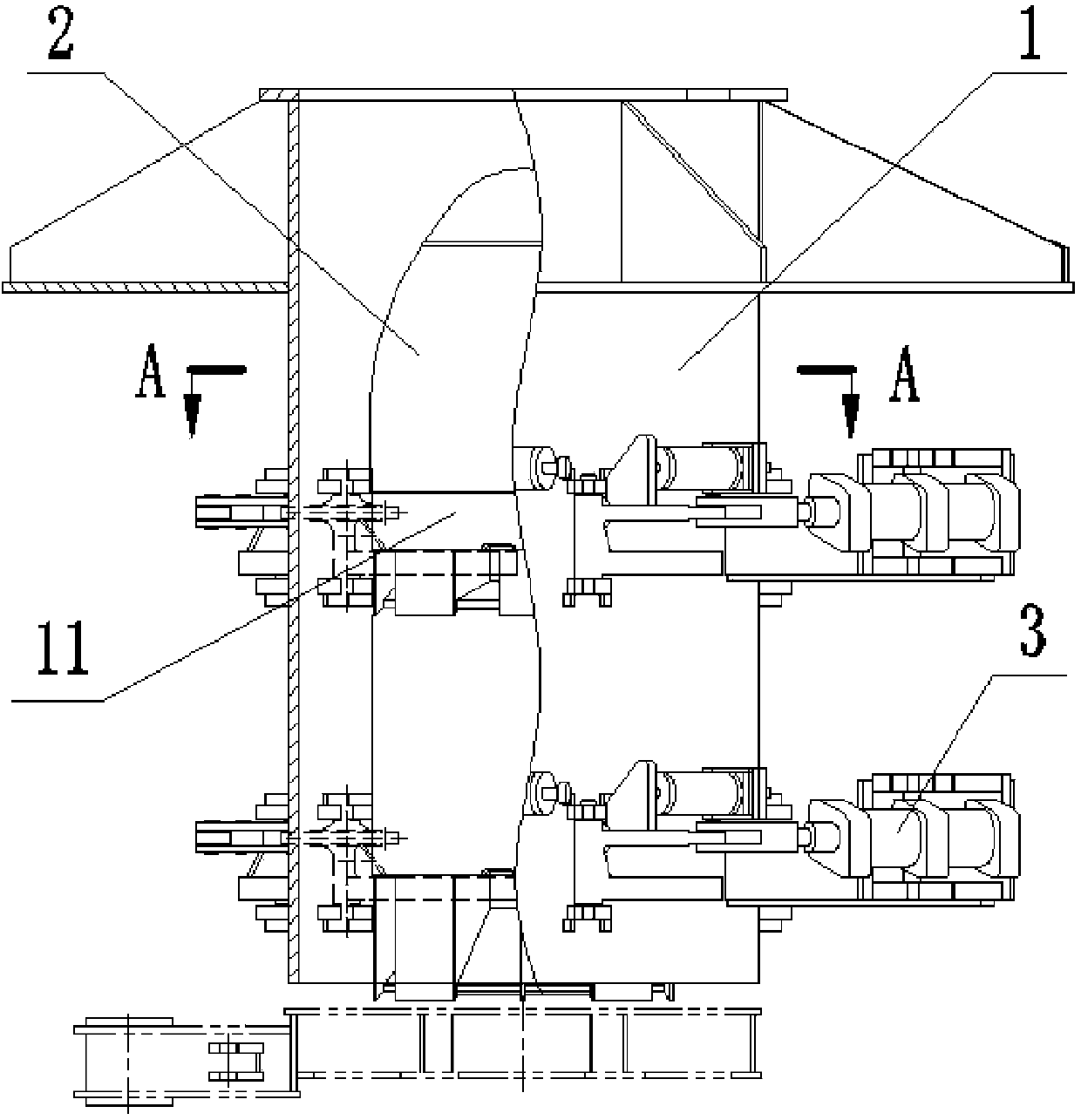

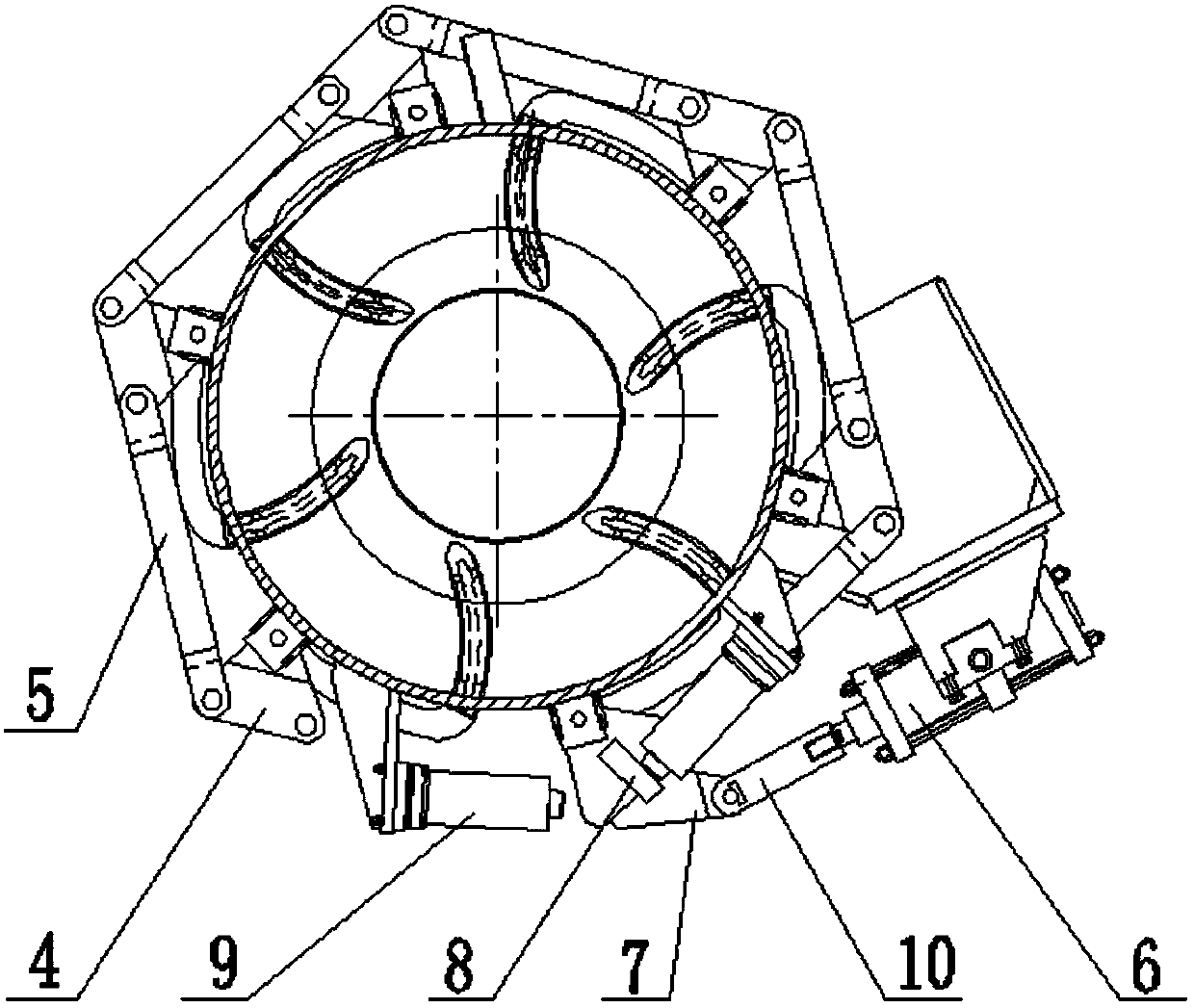

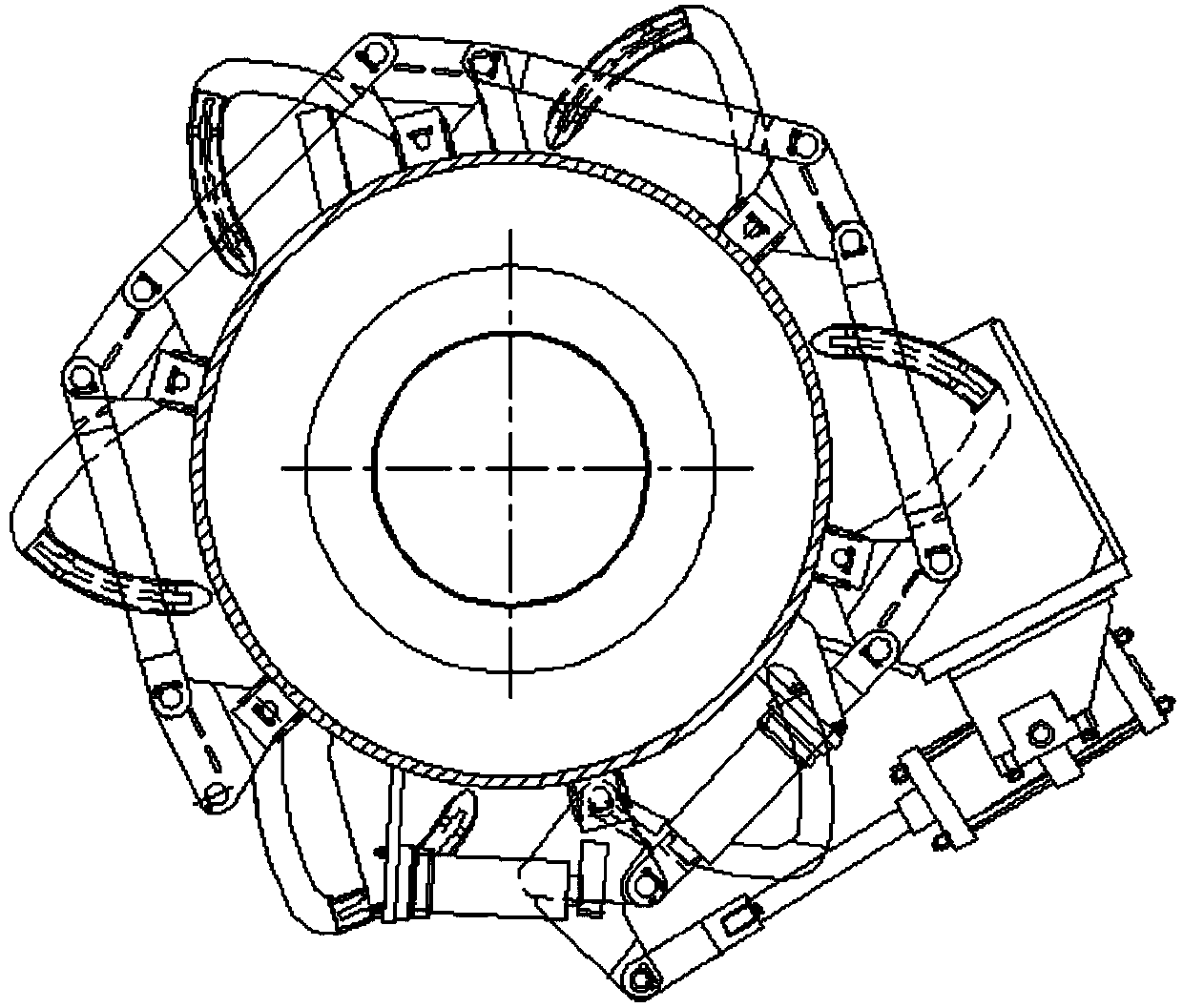

[0022] As shown in the figure, the double-support arm roll collection device in this embodiment includes a roll collection drum 1 and a nose cone 2 arranged at the center of the roll collection drum 1. The temporary support arm 3 for lifting the coil, one group is located at half the height of the collection reel 1, and the other group is located near the bottom of the collection reel 1 slightly higher than the double mandrel position, the temporary support arm 3 is set On the outer wall of the collection reel 1 and circle around the circumferential direction; this embodiment uses two sets of temporary support roll arms 3, when the coil is collected, the upper and lower two sets of temporary support roll arms 3 are closed, and then fall into the set The coil of reel 1 falls on the upper temporary support arm 3. After the coil on the upper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com