Wire drawing device for metal wire

A wire-pulling device and metal wire technology, applied in the field of metal material processing, can solve problems such as time-consuming, labor-intensive, and inability to guarantee quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

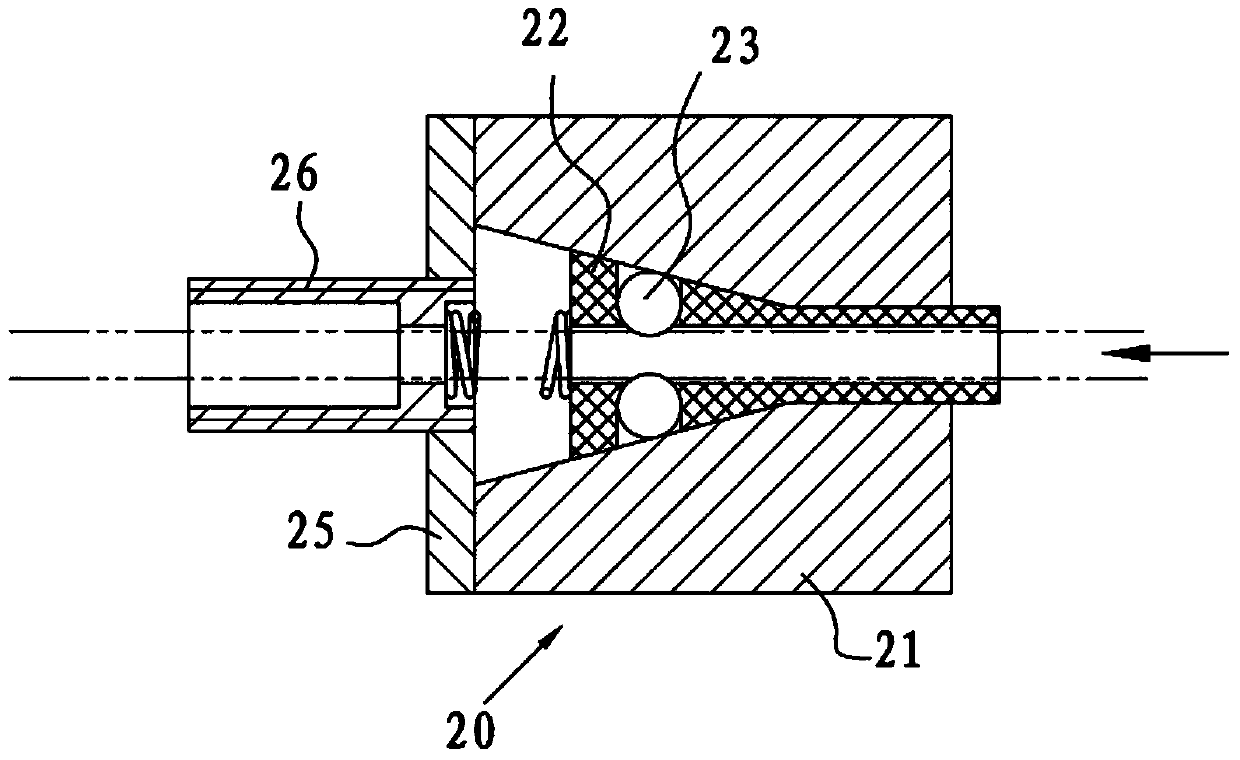

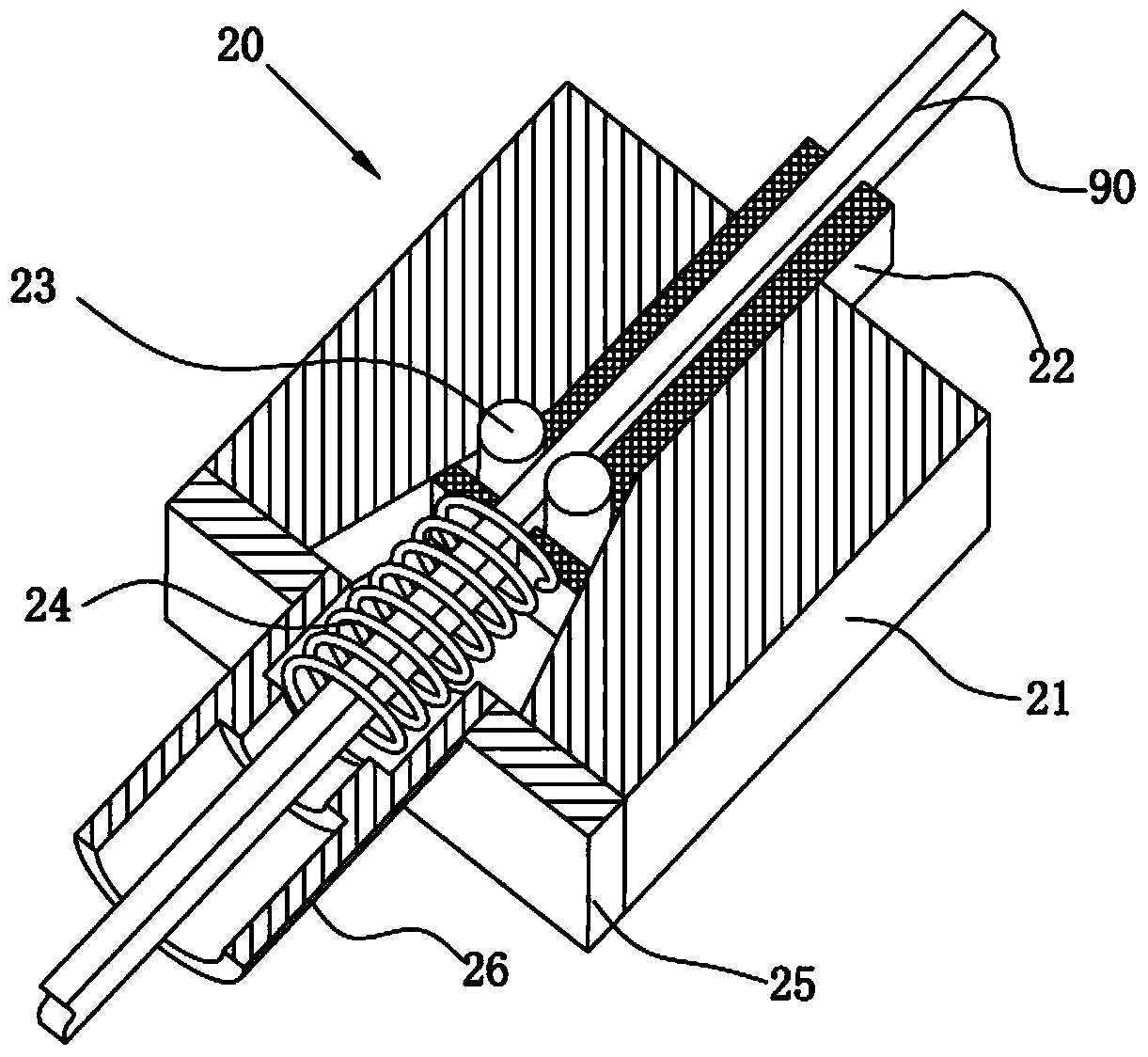

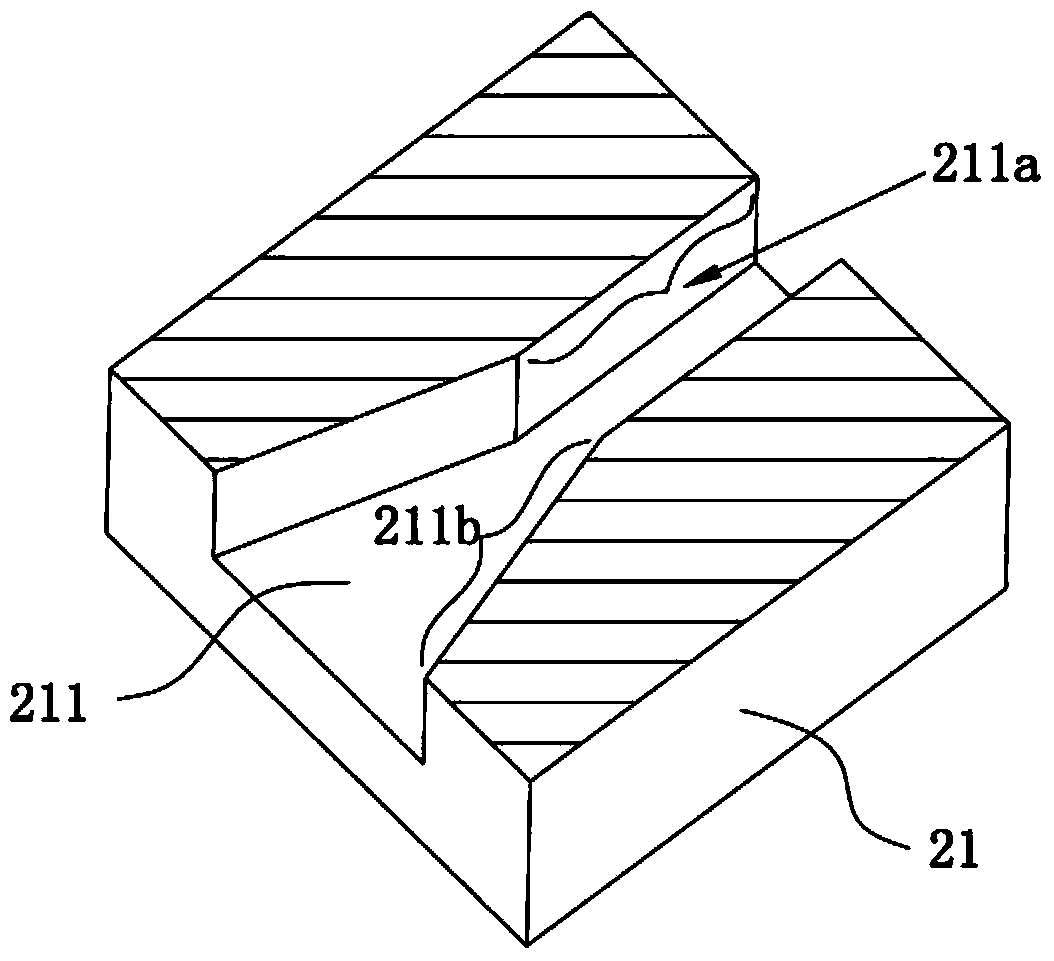

[0012] figure 1 , 5 , The direction indicated by the arrow in 6 is the feeding direction of the metal wire.

[0013] Such as figure 1 , 5 As shown, a metal wire pulling device includes two clamping units 20 arranged on the frame 10, and the two clamping units 20 are arranged in sequence, wherein at least one clamping unit is mobile and the moving direction is the same as the metal to be conveyed The running direction of the thread is the same, and the thread clamping unit 20 is provided with a one-way thread-feeding reverse non-return mechanism. The wire harness 90 can only be fed in one direction in the clamping unit 20, and self-locking will occur when it moves in the opposite direction, so the relative movement between two clamping units 20 arranged in the same direction can make the wire harness 90 move in one direction For this reason, the outlet direction of the clamping unit 20 is defined as the front of the clamping unit 20. One clamping unit 20 is fixed, and when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com