Two-way perforating machine

A punching machine and frame technology, applied in the field of punching machines, can solve the problems of poor quality and accuracy of punching, time-consuming and labor-intensive work, and low work efficiency, so as to increase versatility and improve work efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

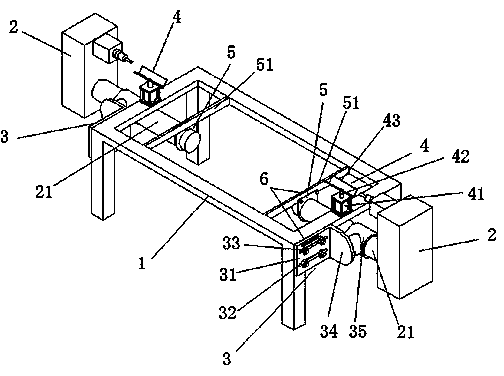

[0016] Example 1, such as figure 1 As shown, a two-way punching machine includes a frame 1, a punching machine 2 symmetrically arranged at both ends of the frame 1, an adjustment device 3 for adjusting the position of the punching machine 2, and a support mechanism 4 for supporting a workpiece; Described adjusting device 3 comprises fixed plate 31, offers two elongated holes 32 on the described fixed plate 31, fixed plate 31 passes bolt 33 in the elongated hole 32 and is fixed on the frame 1, each elongated hole Fix with two bolts 33 in 32. In this way, when adjusting the position of the fixing plate 31 on the frame 1, one can strengthen the connection strength, and the other is to ensure the parallelism of the fixing plate 31. The fixing plate 31 is vertically connected with the connecting plate 34 parallel to the punching direction of the puncher 2, and the connecting plate 34 is fixedly connected with a sleeve 35, and the sleeve 35 is sleeved on the central column 21 fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com