Connecting structure of nested-type composite sectional material

A composite profile and connection structure technology, applied in the direction of building structures, slender elements, building elements, etc., can solve the problems of many components of the connection structure, unfavorable connection structure positioning, inconvenient assembly and disassembly, etc., to improve the connection accuracy and connection strength, prevent deformation and misalignment, and reduce deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

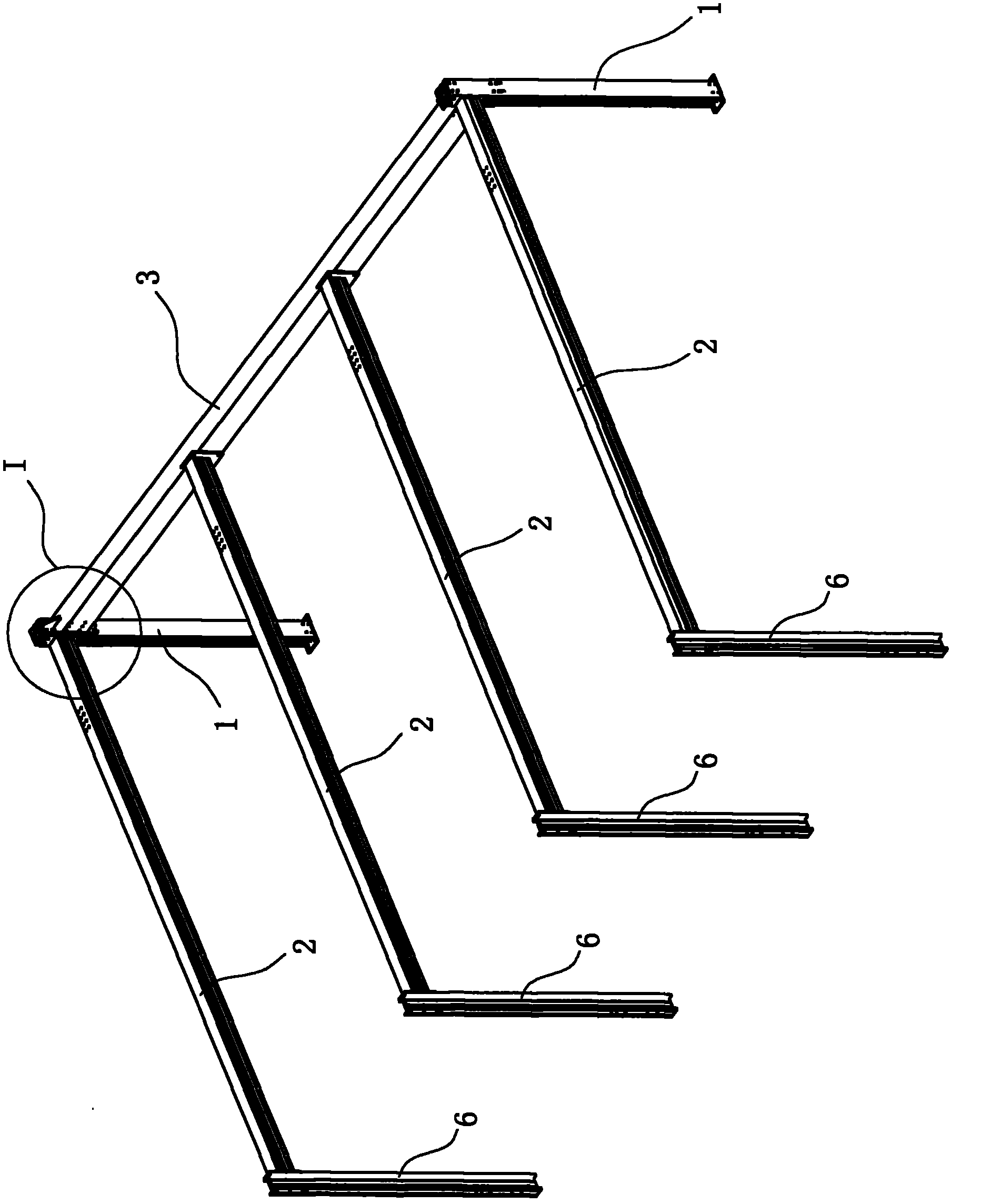

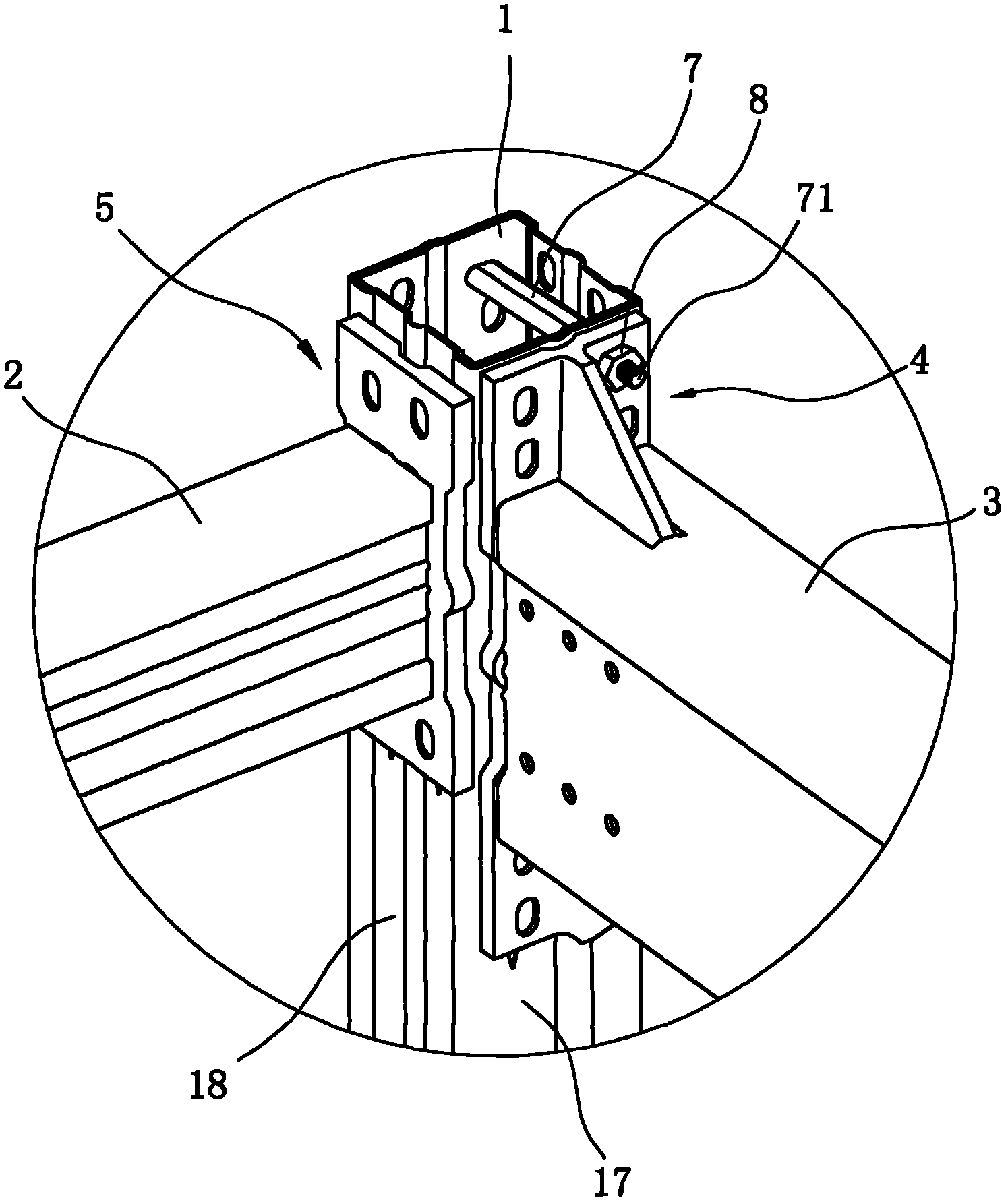

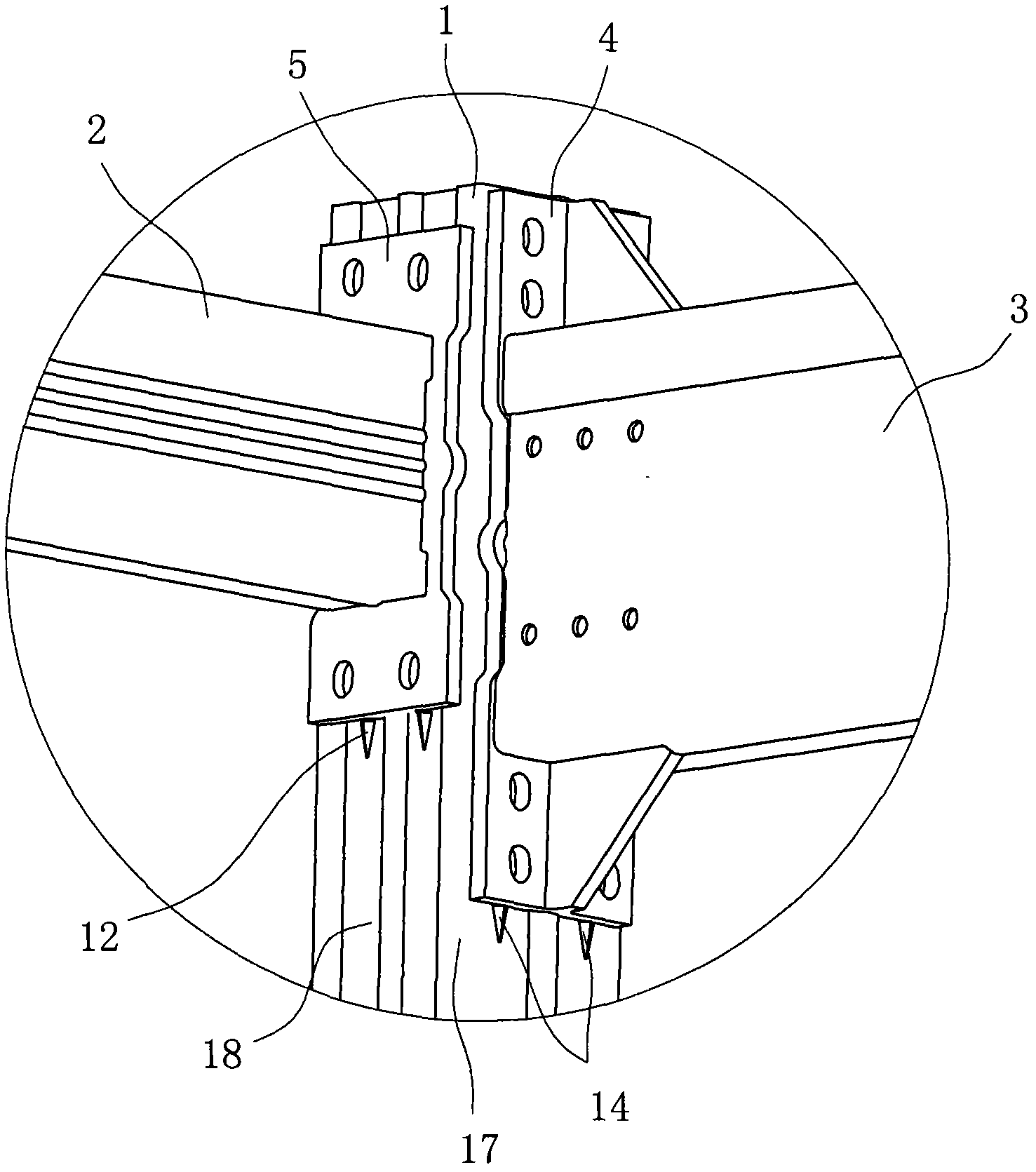

[0024] like Figure 1 to Figure 11 Shown is the beam-column connection structure diagram shown in the three-dimensional garage underframe of this embodiment. The three-dimensional garage underframe includes a column 1, a vertical beam 3, a front beam 2 and a rear column 6, wherein the column 1 and the vertical beam 3 and the vertical connection between the column 1 and the front beam 2 are the invention points of this embodiment. The molding of the column 1, the front beam 2 and the longitudinal beam 3 of this embodiment is different from the traditional casting process. In this embodiment, Column 1, front beam 2 and longitudinal beam 3 respectively adopt nested composite profile structure, and each beam column is cold-rolled respectively, and two first members and second members of the same shape and size are staggered and embraced to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com