High pressure water gun cutting shower nozzle with infrared ray sighting device

A technology of infrared sight and high-pressure water gun, which is applied in metal processing and other directions, can solve the problems of large cutting error and low cutting precision, and achieve the effect of reducing cutting error, simple structure and broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings.

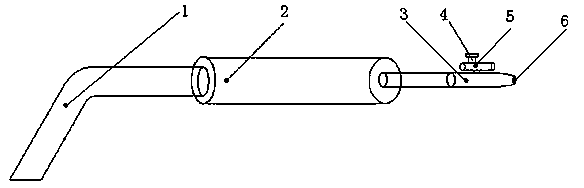

[0014] Such as figure 1 As shown, a high-pressure water gun cutting nozzle with an infrared sight includes: a high-pressure water gun handle 1, a high-pressure water gun tube 2, a high-pressure water gun nozzle 3, an infrared sight 5, and a nozzle 6.

[0015] Such as figure 1 As shown, the high-pressure water gun handle 1 is connected to the high-pressure water gun tube 2, and the high-pressure water gun tube 2 is connected to the high-pressure water gun nozzle 3. The high-pressure water gun tube 2 can store a certain amount of high-pressure water.

[0016] Such as figure 1 As shown, the end of the high-pressure water gun nozzle 3 is equipped with a nozzle 6 and the upper end of the high-pressure water gun nozzle 3 is equipped with an infrared sight 5, which can be used to improve the cutting accuracy of the high-pressure water gun nozzle 3.

[0017] Such as figure 1 As shown, an adjust...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap