Special-type metal thermal transfer production technology

A production process and technology of special-shaped metal, applied in printing, printing device, copying/marking method, etc., can solve the problems of unclear special-shaped metal pattern, unable to meet the requirements of use, and the wood grain and stone grain pattern are not realistic enough for environmental protection. Rich layering, vivid patterns and clear patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

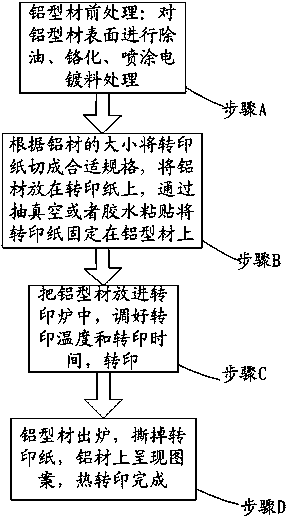

Embodiment 1

[0053] Step A: Aluminum profile pretreatment: degreasing, chromizing, and spraying electroplating treatment on the surface of the aluminum profile. After the surface coating of the aluminum profile is cured, the coating thickness is 50-80 μm, and the coating thickness of the electroplating material is 30-50 μm; step B11: Cut the transfer paper into appropriate specifications according to the size of the aluminum profile, put the aluminum profile on the transfer paper (the printing side faces the sprayed aluminum profile), wrap the aluminum profile with the transfer paper, and do not dry the edge Fix it with glue or tail paper, about every 50CM; Step B12: Cut the PET high-temperature film bag into appropriate specifications according to the size of the aluminum profile, and seal the high-temperature film bag with an edge banding machine to ensure that the edge is firmly sealed and does not leak air (the aluminum profile encapsulated by high-temperature film is cylindrical); Step...

Embodiment 2

[0055]Step A: Aluminum profile pretreatment: degreasing, chromizing, and spraying electroplating treatment on the surface of the aluminum profile. After the surface coating of the aluminum profile is cured, the coating thickness is 50-80 μm, and the coating thickness of the electroplating material is 30-50 μm; step B21: Cut the transfer paper into appropriate specifications according to the size of the aluminum profile, coat the surface of the aluminum profile with glue, then stick the transfer paper on the aluminum profile, and smooth the creases with a cloth; step B22: separate the glued aluminum profiles Put the layer in place, and then use a blade to gently cut off the transfer paper at the groove of the aluminum profile after it is air-dried (the industry calls it "scratch knife", the purpose is to make the transfer paper and the aluminum fully bonded firmly); Step B23: Cut the aluminum profile Put the profile into the transfer furnace at 150°C-220°C, and take it out after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com