Underwater floating body and installing method thereof

An installation method and floating body technology, which are applied in the directions of underwater ships, underwater operation equipment, floating buildings, etc., can solve problems such as difficulty in implementation, and achieve the effects of strong installation controllability, prolonged service life, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

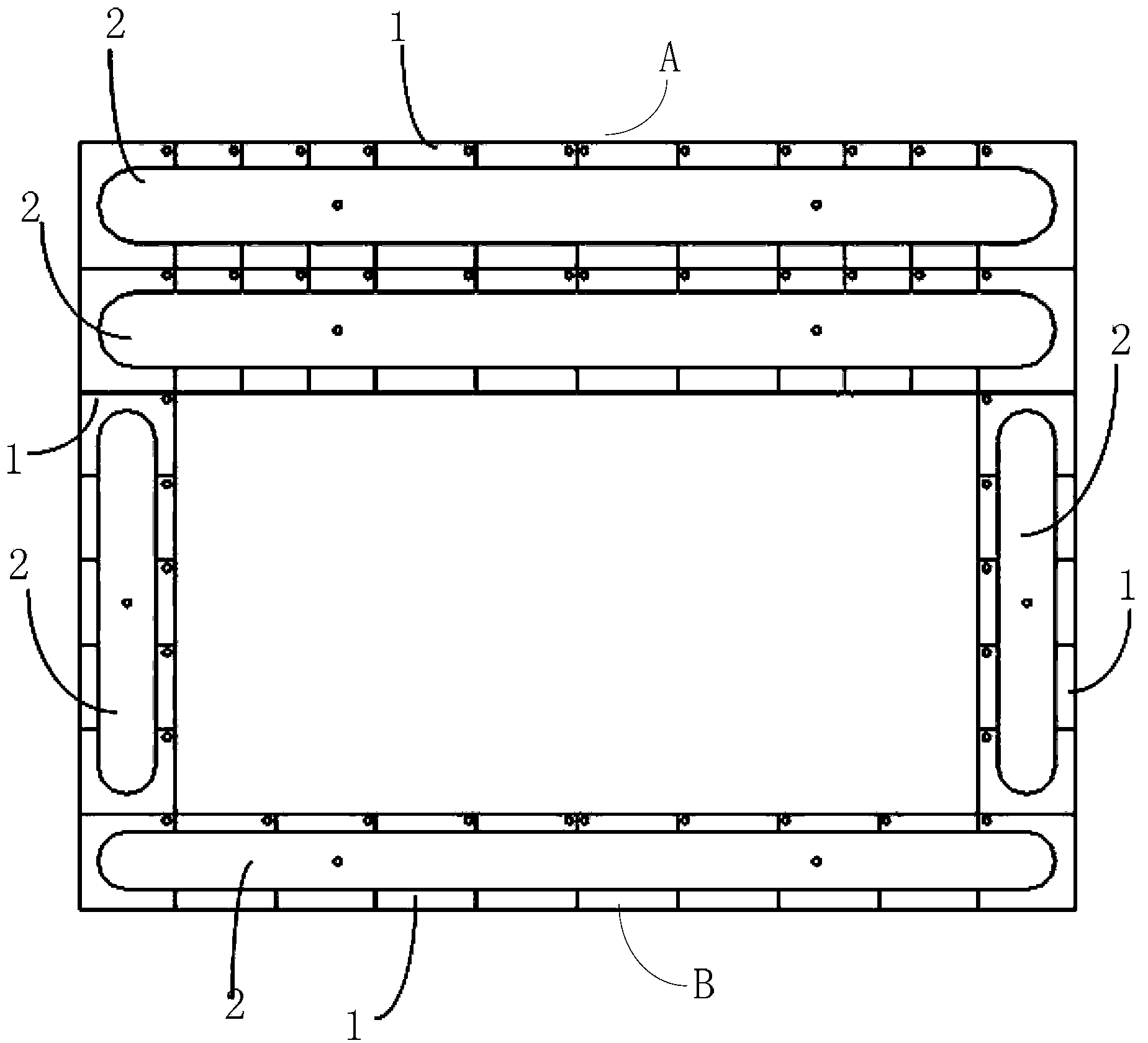

[0019] see figure 1 , The embodiment of the present invention provides an underwater floating body. The underwater floating body is mainly composed of a sub-chamber 1, a pressure-resistant cabin 2, an attitude monitoring system and control equipment. Firstly, the structure of subdivision 1 is introduced. Subdivision 1 is welded by plates of different specifications, specifically: take plates of the same material and thickness, and weld different plates together to form multiple cabins. The plates are selected to be high Strong, corrosion-resistant steel plate. All cabins can be in the shape of a cuboid or a cube, as long as the shape conforms to the design concept of the present invention, it is included in the protection scope of the present invention. Each cabin is a relatively independent closed space. In the actual manufacturing process, a plate with a large area is used as the bottom plate of all cabins. A cabin is called a subdivision1. In this embodiment, all subdivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com