Guide structure for control over inversion of tank body

A guiding structure and tank body technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as difficulty in ensuring the actual weight of canned solids, difficult control of sugar content, and slow production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

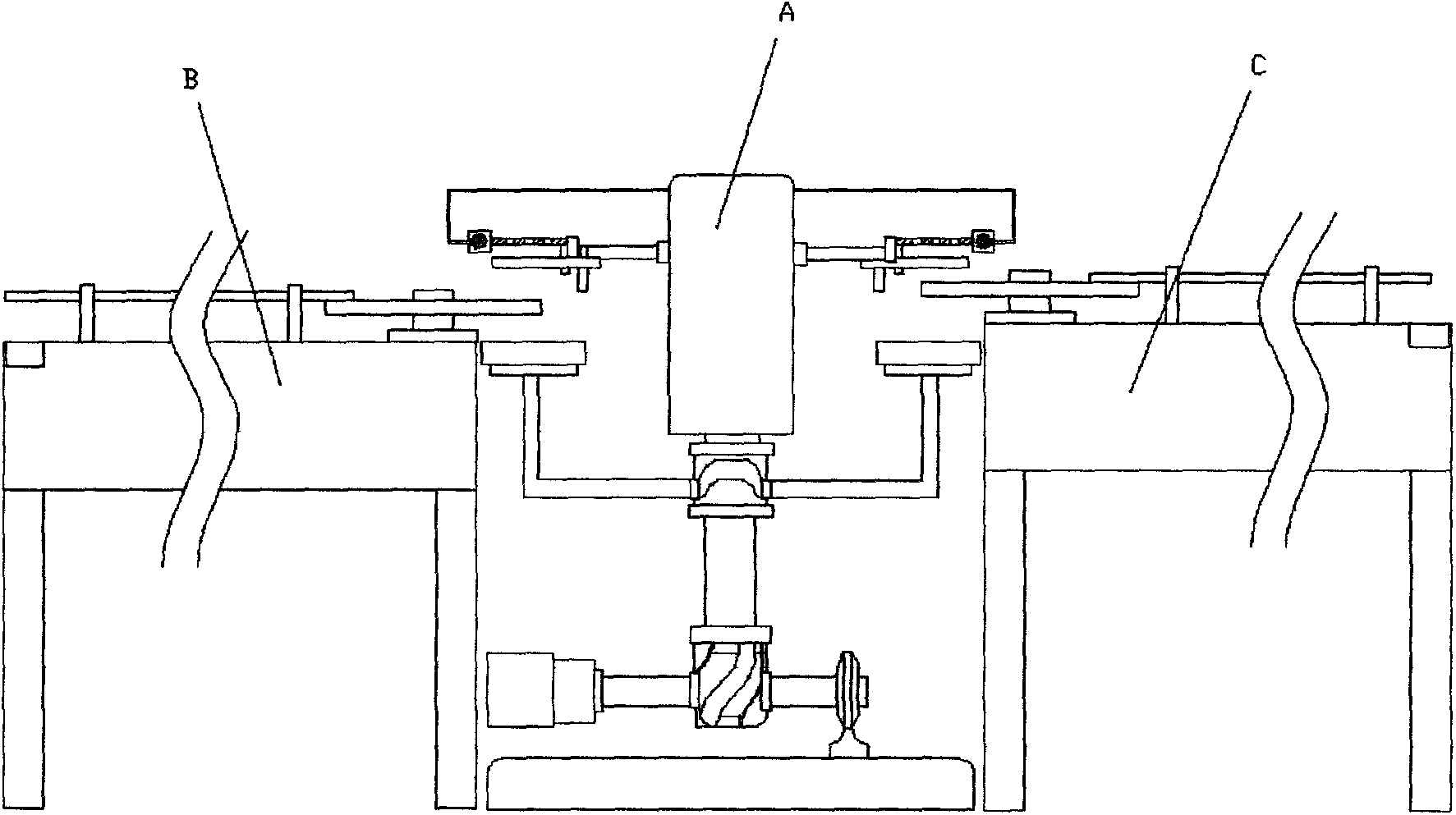

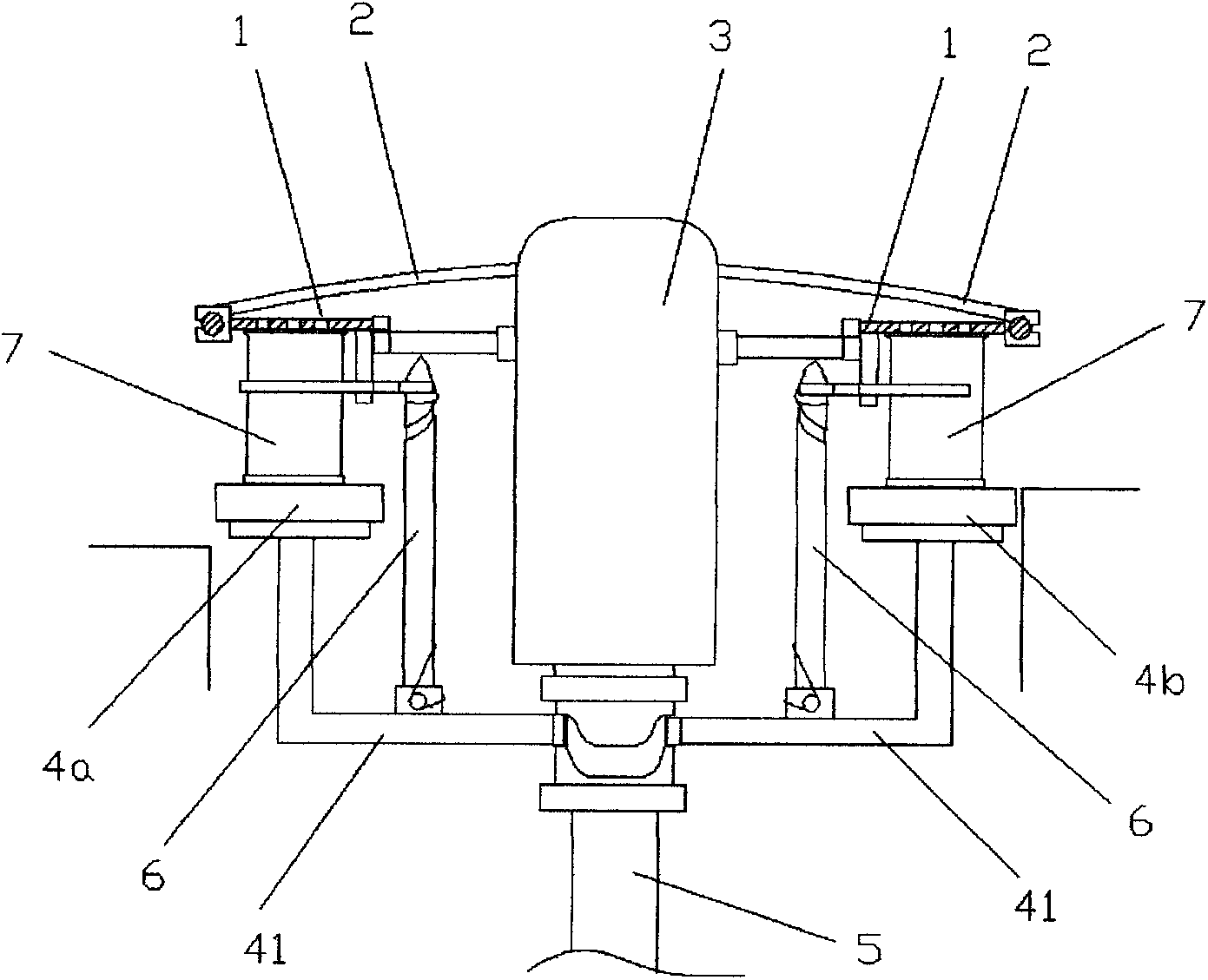

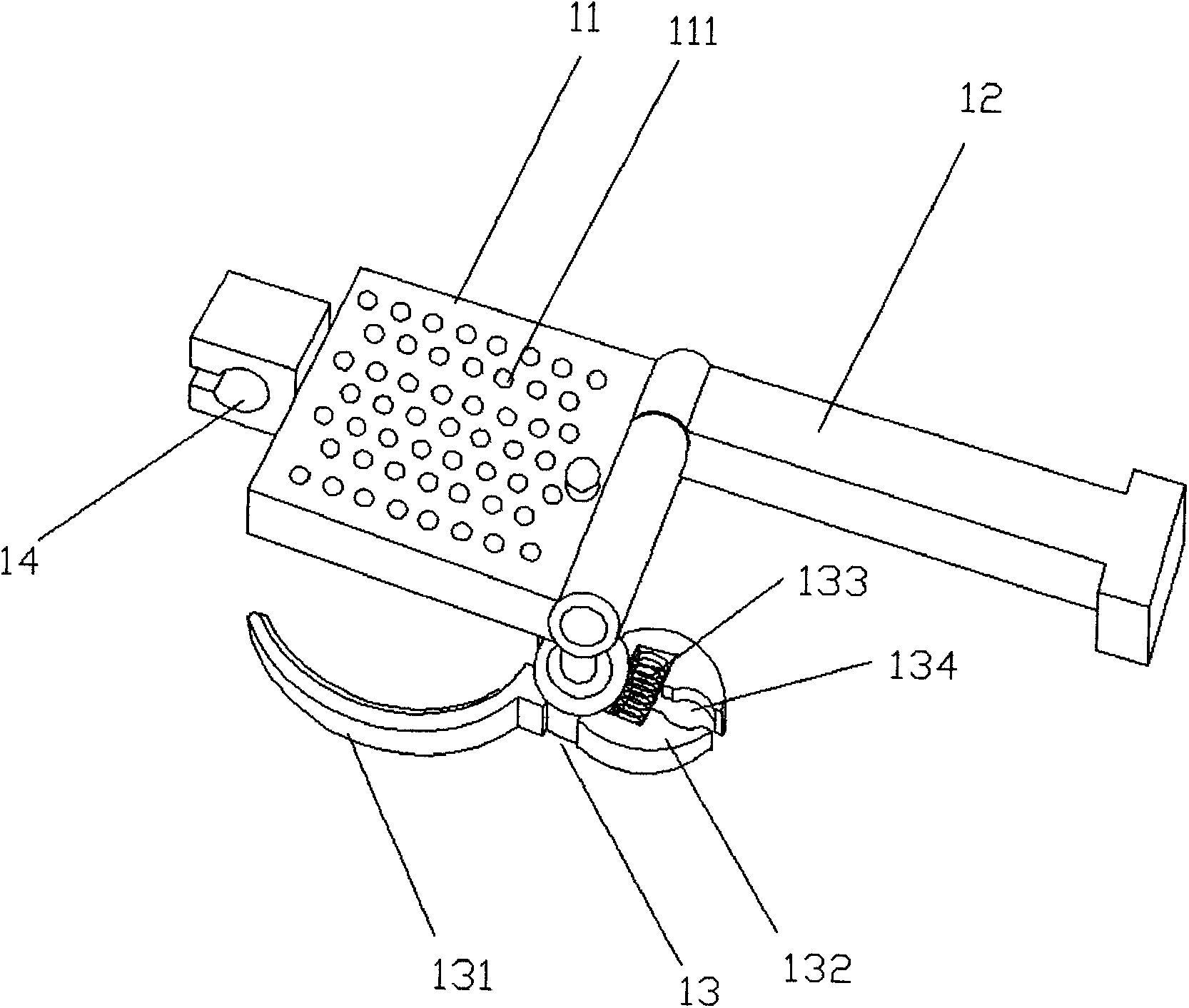

[0027] Embodiment one: if Figure 2-11 As shown, a guiding structure for controlling the inversion of the tank body includes a tank rotating member 1, a track 2, a machine head 3, and a tray. The pallets are the tank-in pallet 4a and the tank-out pallet 4b. The tray and the machine head cooperate with the connected can conveying mechanism to operate. The machine head 3 is connected to the swing rod 12 of the rotating tank member 1, the other end of the swing rod 12 is hinged to the water filtering baffle 11 of the rotating tank member, and the control part 13 for fixing the tank body is connected in parallel to the bottom of the water filtering baffle 11. And corresponding to the tank-in tray 4a and the tank-out tray 4b, a vertical push rod 6 is provided on the horizontal axis 41 of the tank-in tray 4a and the tank-out pallet 4b, and the push rod 6 cooperates with the control member 13, and the water filter baffle plate The opening hole 14 at one end of 11 is sleeved on the ...

Embodiment 2

[0031] Embodiment two: if Figure 7 , 8 , 9, on the straight line from the tank-in pallet 4a to the tank-out pallet 4b, the radian of the track 2 is left-right symmetrical, and the distance H1 between the track 2 above the two pallets and the machine head 3 is a two-phase hinged swing bar 12 and The linear length after the water filter baffle 11 stretches in parallel. The rail 2 is located at the shortest distance H3 from the nose 3, so that the rail 2 leans against the side wall of the nose 3. When the tumbler component 1 slides along the track 2 with the rotation of the machine head 3 until the track 2 is at the closest distance H3 from the machine head 3, that is, when the track is against the side wall of the machine head, the tumbler component 1 is positioned on the track 2, the water filter baffle 11 of the rotary tank member 1 has been rotated at an angle of 180°, the water filter baffle 11 is superimposed on the top of the swing rod 12, and the tank body 7 also stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com