Crane lifting mechanism and centralizing guide device

A technology of guiding device and hoist, applied in the direction of lifting device, etc., can solve problems such as shaking and inaccurate positioning, and achieve the effect of high rigidity, overcoming shaking and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

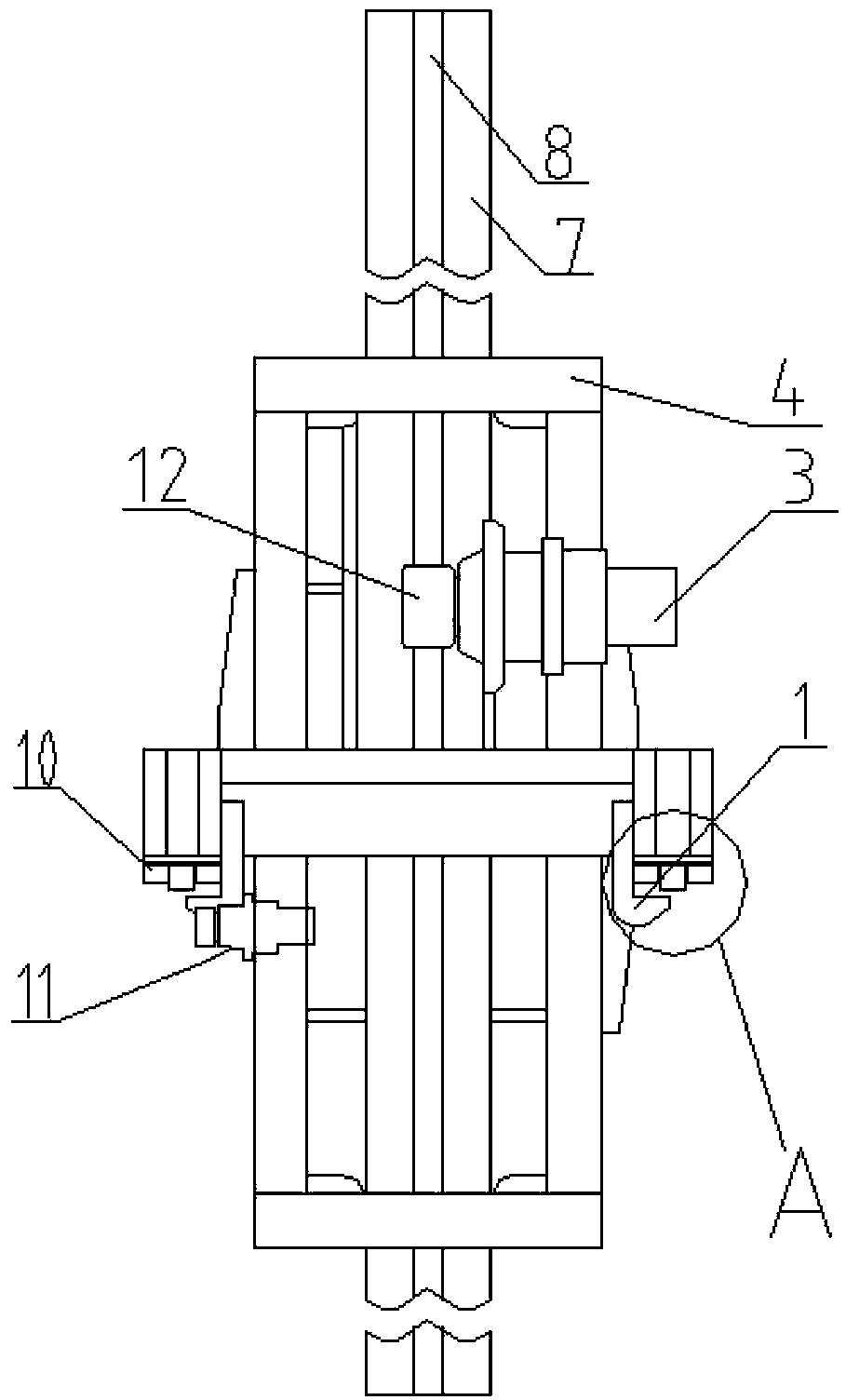

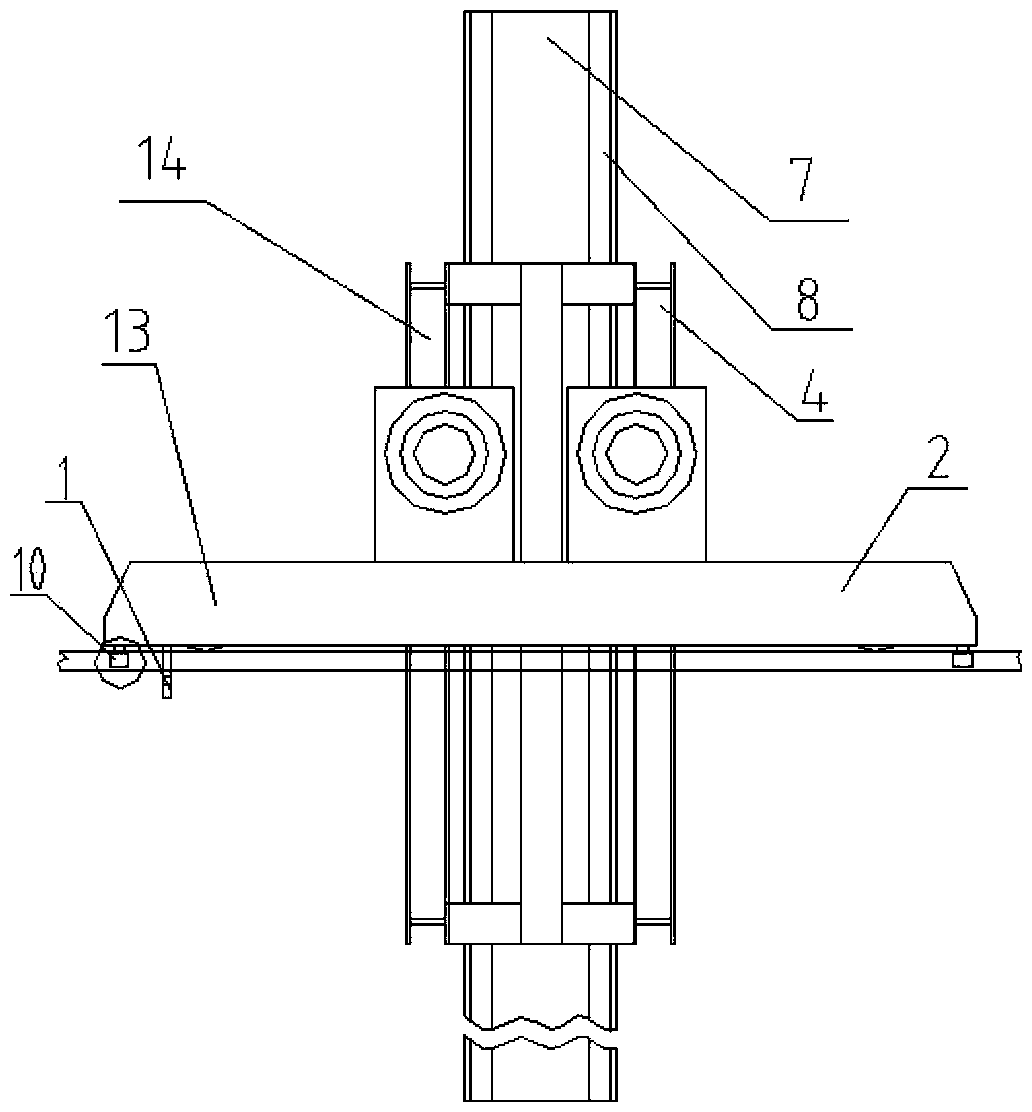

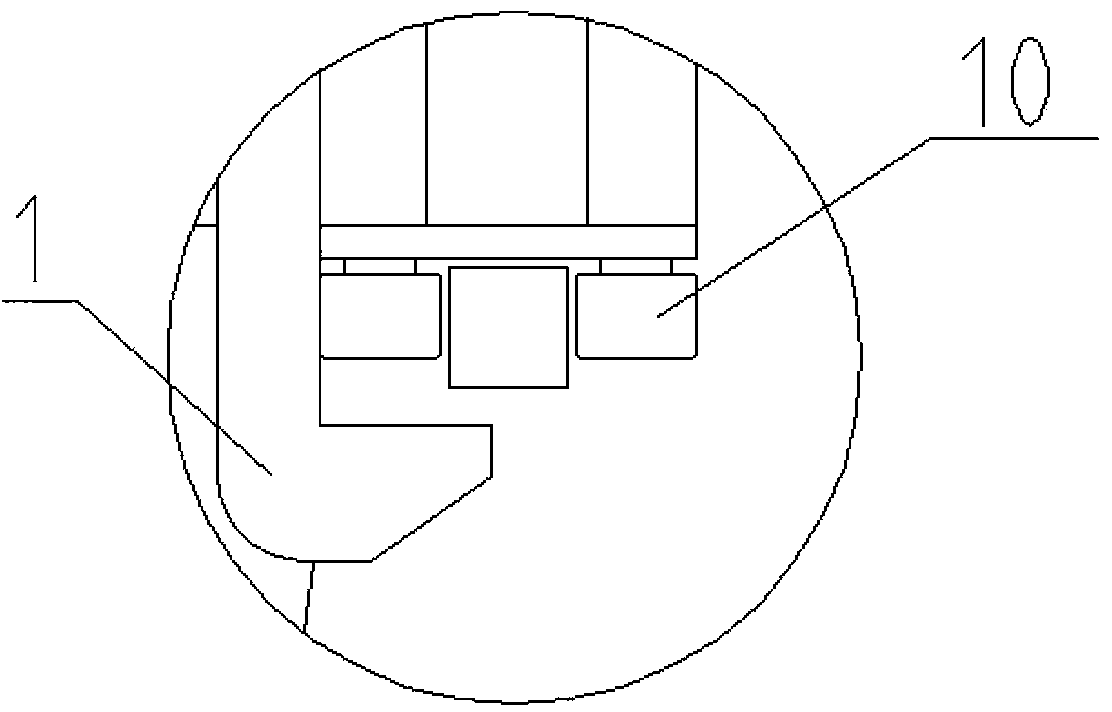

[0024] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0025] An embodiment of the present invention is a crane lifting mechanism and a righting guide device, which includes a traveling mechanism 13 and a lifting guide mechanism 14;

[0026] The lifting guide mechanism 14 includes: a lifting hydraulic motor 3, a righting guiding device frame 4, an adjusting gasket 5, a guide wheel 6, a lifting rod 7, and a rack 8, and the lifting hydraulic motor 3 and the righting guiding device frame 4 are installed on On the mobile trolley 2 of the walking mechanism 13, the rack 8 is fixed vertically and symmetrically on both sides of the lifting rod 7, and the lifting rod 7 vertically passes through the frame 4 of the righting guide device, and on the The upper and lower ends of the righting guide device frame 4 are provided with the guide wheels 6, the guide wheels 6 support the lifting rod 7 and limit the movement of the lifting rod 7 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com