Parallel sludge low-temperature drying method utilizing waste heat of flue gas

A flue gas waste heat, parallel technology, used in dehydration/drying/concentrated sludge treatment, waste heat treatment, lighting and heating equipment, etc., can solve problems such as energy consumption bottlenecks, improve efficiency, overcome energy bottlenecks, and increase energy The effect of utilization efficiency

Active Publication Date: 2013-12-11

ZHEJIANG UNIV

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, thermal drying of sludge is a process of net energy consumption, and energy consumption usually acco

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

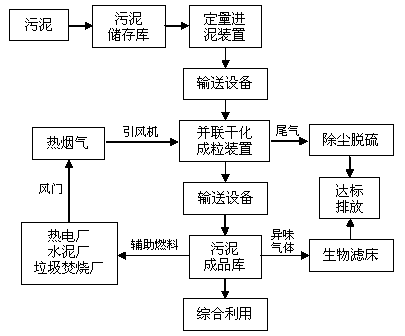

The invention discloses a parallel sludge low-temperature drying method utilizing waste heat of flue gas. The parallel sludge low-temperature drying method comprises the following steps; 1, sending the flue gas discharged by a thermal power plant, a cement plant and a waste incineration plant into two parallel sludge drying granulating apparatus by induced draft fans to carry out sludge low-temperature drying and granulating process; 2, pouring sludge from a sewage treatment plant or dredging of rivers and lakes into a sludge hopper by a sludge conveying vehicle; 3, uniformly dividing and sending the sludge into two pieces of conveying equipment by a double-screw thruster at the bottom of the sludge hopper through separators arranged at sludge outlets; 4, respectively, continuously and quantitatively sending the sludge into the two parallel sludge drying granulating apparatus by the conveying equipment, enabling the sludge to be in direct contact with the heat flue gas, performing the heat exchange reaction, evaporating water in the sludge and naturally granulating; 5, sending the dried sludge particles into a finished product warehouse by the conveying equipment; 6, carrying out dry-wet multi-stage dust removal and desulfuration on tail gas discharged after the sludge is dried, so that the tail gas reaches the standard to be discharged.

Description

technical field [0001] The invention relates to a parallel sludge low-temperature drying method utilizing waste heat of flue gas. Background technique [0002] Urban domestic sewage and industrial wastewater are treated and discharged up to standard, which is an indispensable environmental engineering measure for the protection of the ecological environment. By 2010, my country's urban sewage treatment rate will not be lower than 70%. By the end of June 2012, the national urban sewage treatment volume has reached 139 million cubic meters per day. During the purification process of urban domestic sewage and industrial wastewater, a large amount of sludge will be produced. The amount of sludge produced in my country has reached 34.8 million tons per year, and it is increasing at a growth rate of 10-15% every year. The sludge produced by urban sewage treatment plants is composed of complex heterogeneous bodies such as organic debris, bacterial cells, inorganic particles, and c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F11/12F27D17/00

CPCY02P10/25

Inventor 翁焕新苏闽华陈海燕

Owner ZHEJIANG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com