Parallel sludge low-temperature drying system utilizing waste heat of flue gas

A flue gas waste heat, parallel technology, used in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve problems such as energy consumption bottlenecks, and ensure discharge and efficiency The effect of improving and improving the efficiency of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

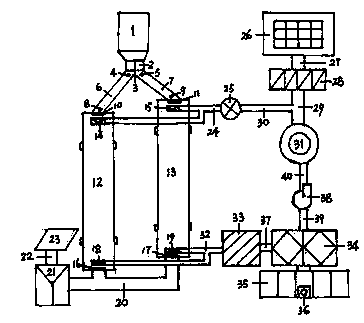

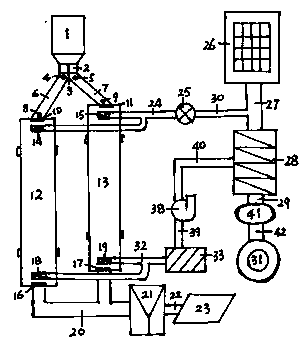

[0019] Such as figure 1 As shown, a parallel sludge low-temperature drying system utilizing flue gas waste heat includes a sludge hopper 1 of a double-screw quantitative sludge feeding device, a sludge outlet 2, a separation plate 3, the first screw conveyor inlet 4, and the second screw conveyor. Screw conveyor inlet 5, the first screw conveyor 6, the second screw conveyor 7, the first screw conveyor outlet 8, the second screw conveyor outlet 9, the first sludge drying and granulating device inlet 10, the second screw conveyor Second sludge drying and granulating device feed port 11, first sludge drying and granulating device 12, second sludge drying and granulating device 13, first sludge drying and granulating device inlet 14, second sludge drying and granulating device The air inlet 15 of the granulation device, the discharge port 16 of the first sludge drying granulation device, the discharge port 17 of the second sludge drying granulation device, the air inlet 18 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com