Double-layer corrugated steel plate and composite structure partition wall

A corrugated steel plate and composite structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of small distance between two steel plates, difficult positioning and fixing of two steel plates, and slurry leakage, and achieve the effect of preventing left and right translation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

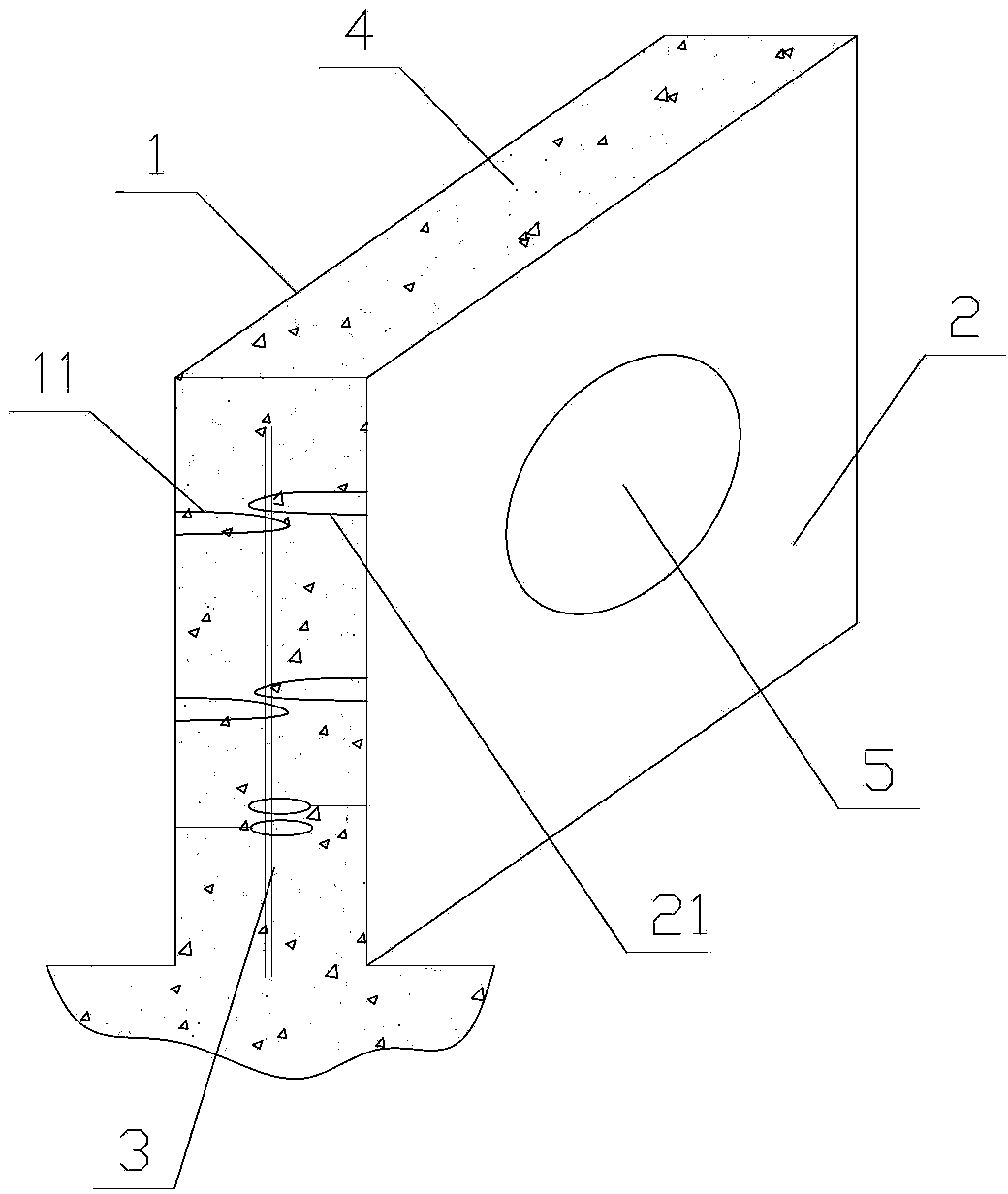

[0025] Double-layer corrugated steel plate composite structure partition wall, such as figure 1 , 2 As shown, it includes A corrugated steel plate 1 and B corrugated steel plate 2. A connector 11 is provided on the inner side of the A corrugated steel plate 1, and a B connector 21 is provided on the inner side of the B corrugated steel plate 2. The A connector 11 and the B connector 21 Connected by connecting device 3 , reinforced concrete 4 is set between A corrugated steel plate 1 and B corrugated steel plate 2 . When pouring concrete between double-layer steel plates, due to the small distance between the steel plates, the staff cannot perform welding operations between the two steel plates; Bolting is used to control the distance between the two steel plates and to support and fix the two steel plates. However, on the one hand, the opening connection method will destroy the continuity of the entire steel plate and affect the overall structural strength of the steel plate....

Embodiment 2

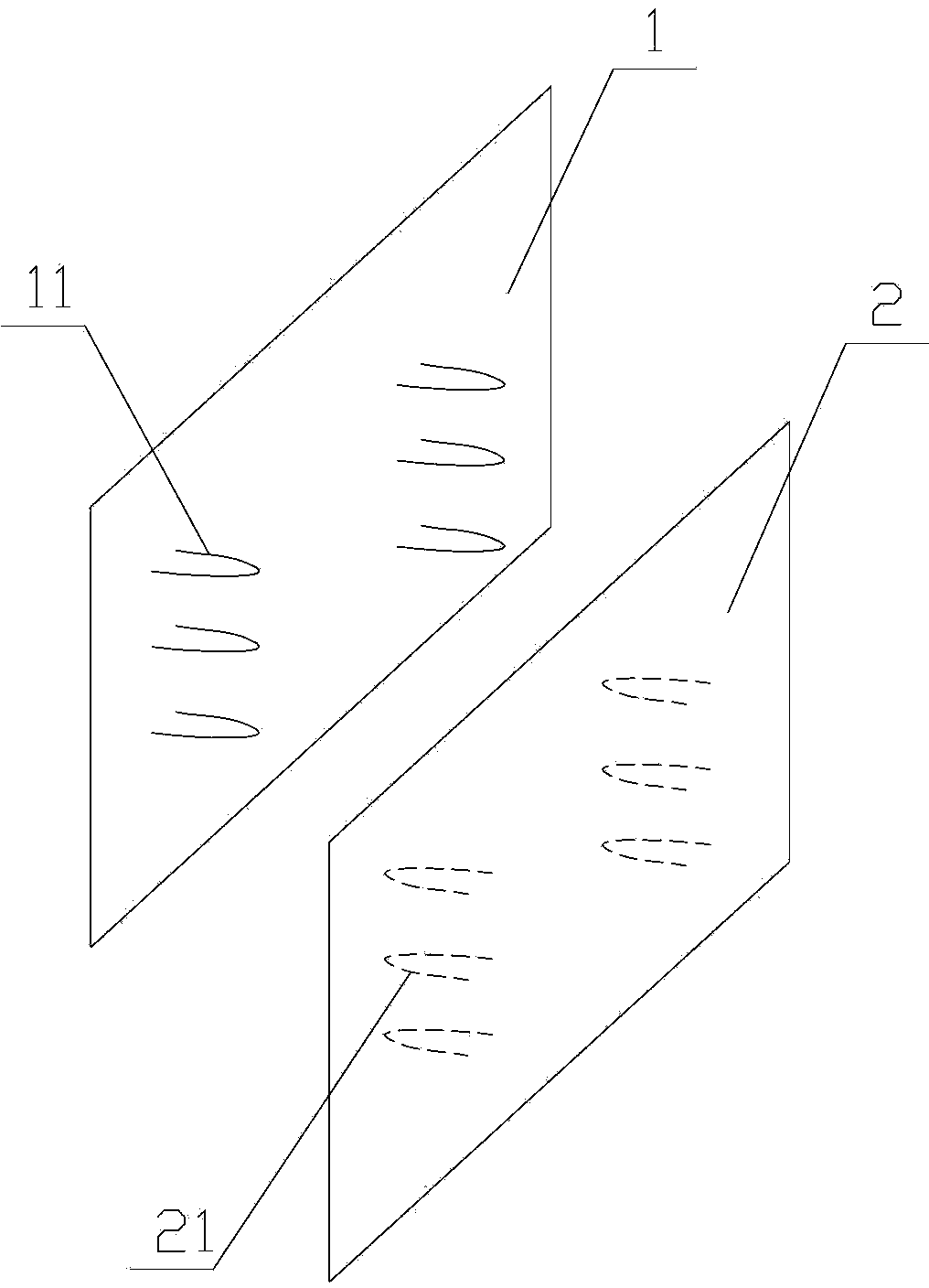

[0030] Double-layer corrugated steel plate composite structure partition wall, such as figure 1 , 2 As shown, the difference between this embodiment and Embodiment 1 is that the A connector 11 and the B connector 21 are U-shaped steel bars, and the U-shaped steel bars are misplaced. The rod is connected to pass through the intersecting hole where the U-shaped steel bars displace and intersect, and connect the A corrugated steel plate 1 and the B corrugated steel plate 2 together. The connecting rod can also be a steel bar, and the A connector 11 and the B connector 21 are connected through the connecting device 3 . The connection piercing rod is used to penetrate the U-shaped steel bars respectively provided on the A corrugated steel plate 1 and the B corrugated steel plate 2, so as to realize the purpose of connecting the A corrugated steel plate 1 and the B corrugated steel plate 2 together, and has the advantages of simple operation and high installation efficiency.

Embodiment 3

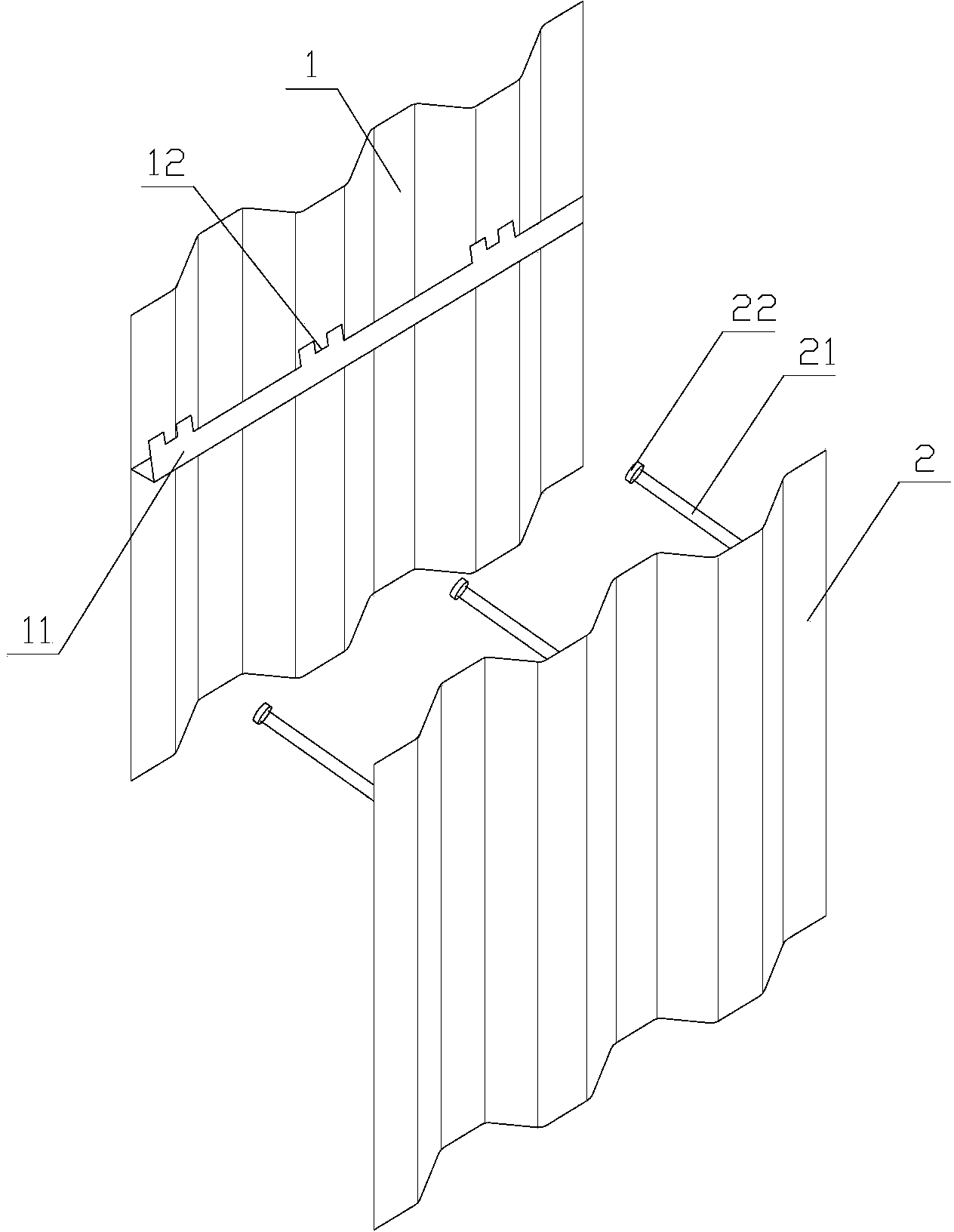

[0032] Double-layer corrugated steel plate composite structure partition wall, such as figure 1 , 3 , 5, including A corrugated steel plate 1 and B corrugated steel plate 2, the inner side of the A corrugated steel plate 1 is provided with an A connector 11, and the inner side of the B corrugated steel plate 2 is provided with a B connector 21, and the A connector 11 is connected to B The head 21 is directly connected, and reinforced concrete 4 is arranged between the A corrugated steel plate 1 and the B corrugated steel plate 2 . When pouring concrete between double-layer steel plates, due to the small distance between the steel plates, the staff cannot perform welding operations between the two steel plates; Bolting is used to control the distance between the two steel plates and to support and fix the two steel plates. However, on the one hand, the opening connection method will destroy the continuity of the entire steel plate and affect the overall structural strength of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com