A segmented transmission mechanism for industrial heating furnace

A technology of transmission mechanism and heating furnace, which is applied in the direction of transmission belt, transmission device, lighting and heating equipment, etc., can solve the problems of increasing cooling area and increasing equipment cost, and achieve the effect of increasing cooling rate, saving cost and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

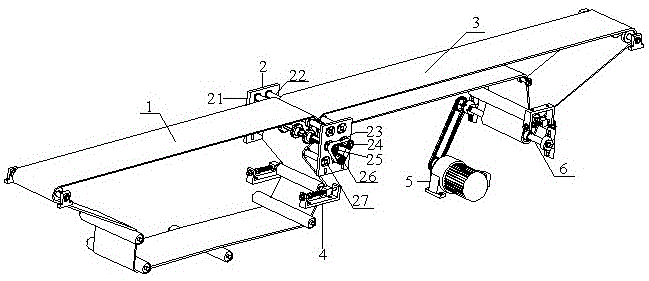

[0024] like figure 1 A segmented transmission mechanism for an industrial heating furnace shown includes a heating section transmission mechanism 1 and a cooling section transmission mechanism 3 , and the heating section transmission mechanism 1 and the cooling section transmission mechanism 3 are connected through a transition transmission mechanism 2 . Specifically, the transmission mechanism of the heating section and the transmission mechanism of the cooling section work independently of each other, and the mesh belts used by the two transmission mechanisms are not the same mesh belt. In this way, it is avoided that the mesh belt brings the heat absorbed by the heating section to the cooling section, which affects the cooling efficiency of the workpiece, and at the same time increases the length of the cooling section and increases the equipment cost.

[0025] Further,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com