Water-cooling heat dissipation device for electrical equipment

A technology for water-cooled heat dissipation and electrical equipment, which is used in cleaning heat transfer devices, lighting and heating equipment, cooling/ventilation/heating renovation, etc. Increase the contact area between the heat pipe and the dust in the air to achieve the effect of promoting the collection efficiency and reducing the reverse flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

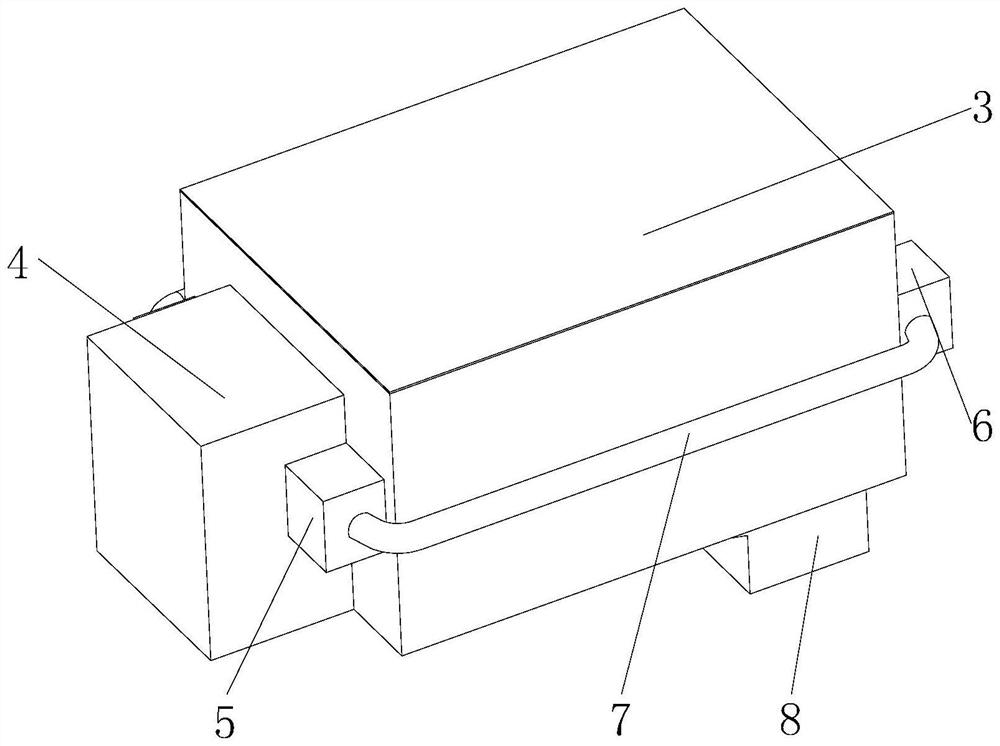

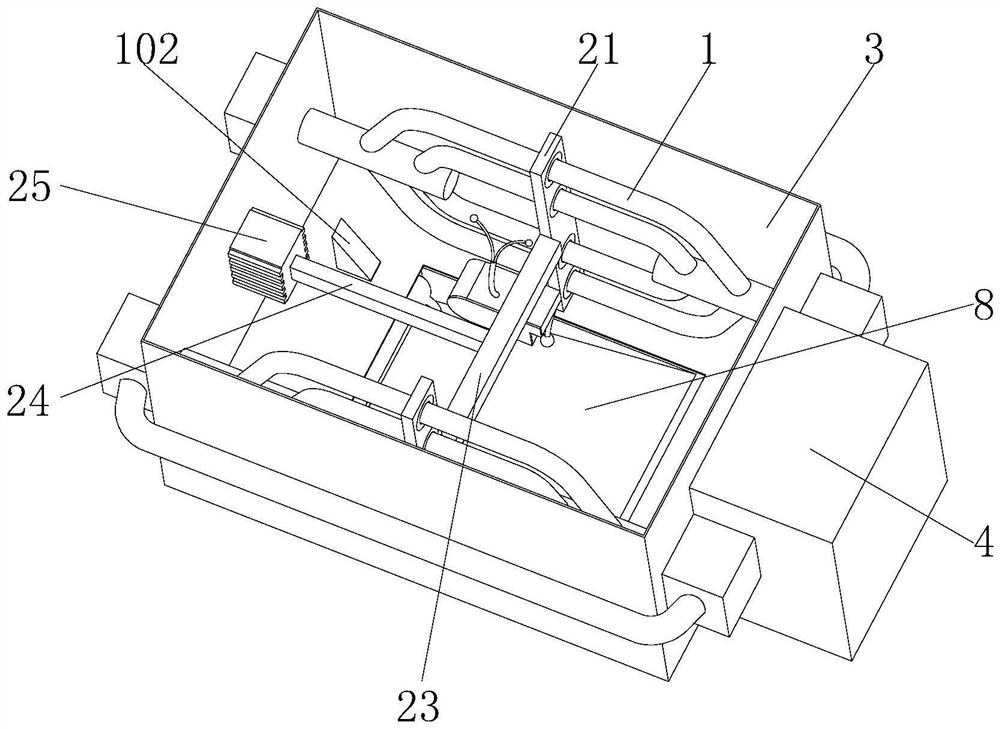

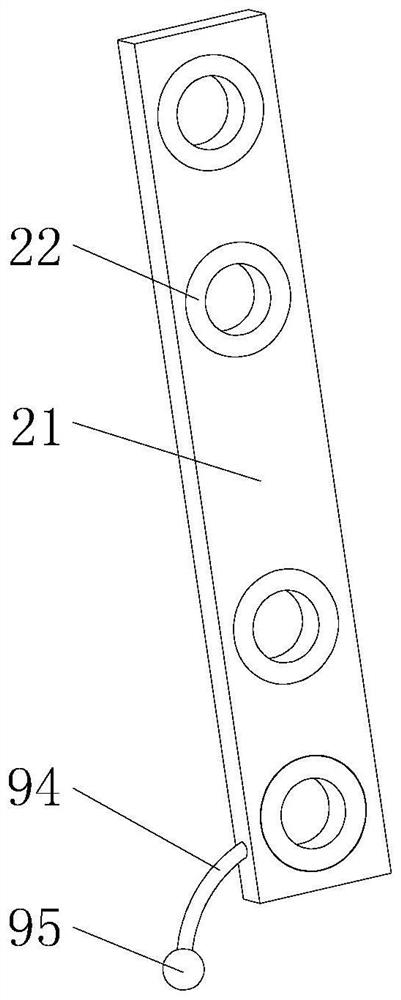

[0029] see Figure 1-6 , the present invention provides a technical solution: a water-cooled heat dissipation device for electrical equipment, including a heat dissipation pipe 1, a cleaning mechanism is provided outside the heat dissipation pipe 1, and the cleaning mechanism includes a socket plate 21, a cleaning soft brush 22, a connecting plate 23, and a telescopic rod 24 and the linear motor 25, the sleeve plate 21 is slidably sleeved on the outer wall of the heat pipe 1, the outer end of the cleaning soft brush 22 is fixedly installed on the sleeve plate 21, the inner end of the cleaning soft brush 22 is set close to the outer wall of the heat pipe 1, and the connecting plate 23 is embedded in the outer wall of the socket plate 21, one end of the telescopic rod 24 is embedded in the outer wall of the connecting plate 23, the other end of the telescopic rod 24 is embedded in the output end of the linear motor 25, and the linear motor 25 is fixedly installed on the inner wal...

Embodiment 2

[0032] like figure 2 , Figure 4 and Figure 5 As shown, on the basis of Embodiment 1, in this embodiment, a collection tank 8 is fixedly installed at the bottom of the electrical box 3, the entrance of the collection tank 8 is arranged in an inclined shape, and a restriction mechanism is provided on the collection tank 8, and the restriction mechanism includes The partition 91, the elastic air bag 92 and the blowing pipe 93, the partition 91 is fixedly installed on the inner wall of the collection tank 8, there is a certain gap between the bottom of the partition 91 and the collection tank 8, the elastic air bag 92 is fixedly installed on the partition 91, blowing The trachea 93 is fixedly installed on the elastic air bag 92, and the bottom of the socket plate 21 is provided with a pressing mechanism. The pressing mechanism includes an arc-shaped fixing rod 94 and a squeezing ball 95. The other end of the arc-shaped fixing rod 94 is fixedly installed with a squeeze ball 95...

Embodiment 3

[0035] like figure 2 and Figure 4 As shown, on the basis of Embodiment 1, in this embodiment, a compaction mechanism is provided on the collection tank 8, and the compaction mechanism includes a compaction plate 101, a sliding rod 102 and a push box 103, and the compaction plate 101 is slidably installed on the On the inner wall of the collection tank 8, the top of the compaction plate 101 and the inner wall of the collection tank 8 are elastically connected by elastic pieces, the bottom of the sliding rod 102 is embedded on the top of the compaction board 101, the sliding rod 102 penetrates and is slidably installed on the bottom of the electrical box 3, and the sliding The upper right end of the rod 102 is set as an inclined surface, the push box 103 is fixedly installed on the outer wall of the socket plate 21, and the sliding rod 102 has magnetism. The collected impurities and dust are compacted to increase the collection capacity.

[0036] When working, when the socke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com