Rapid cooling device for intelligent temperature detection for injection molding

An injection molding and rapid cooling technology, applied in the field of injection molds, can solve the problems of lack of temperature adjustment equipment, affecting the quality of material molding, affecting the production cost of workpieces, etc., to avoid cooling efficiency, avoid non-standard molding, and improve molding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

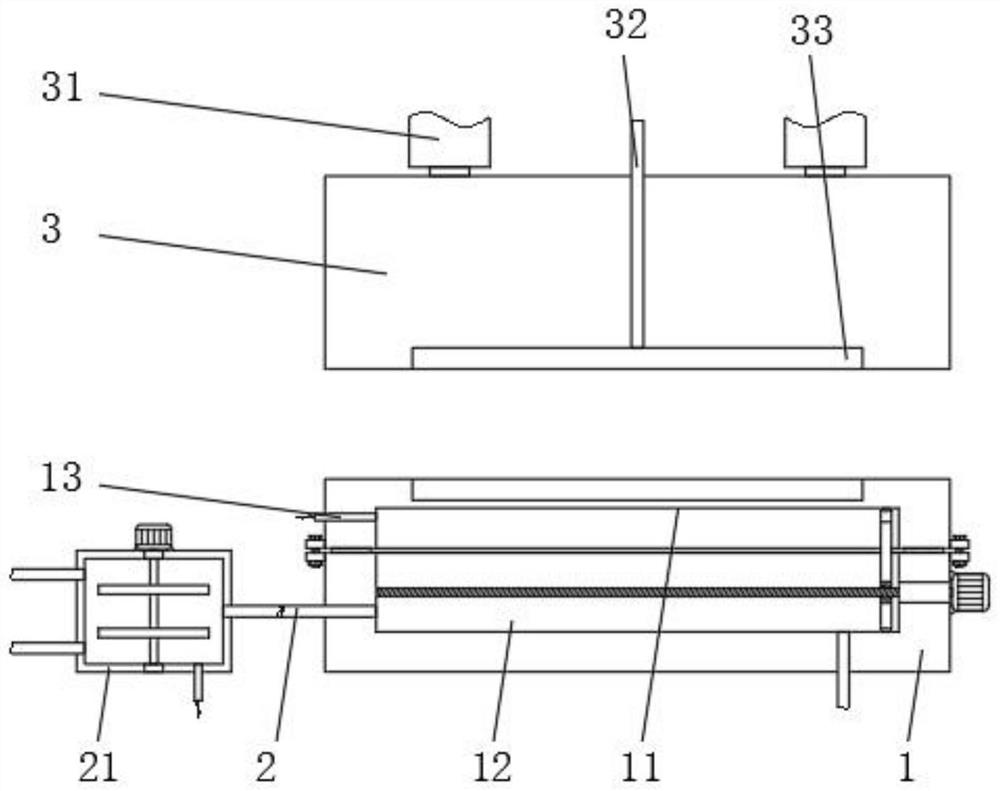

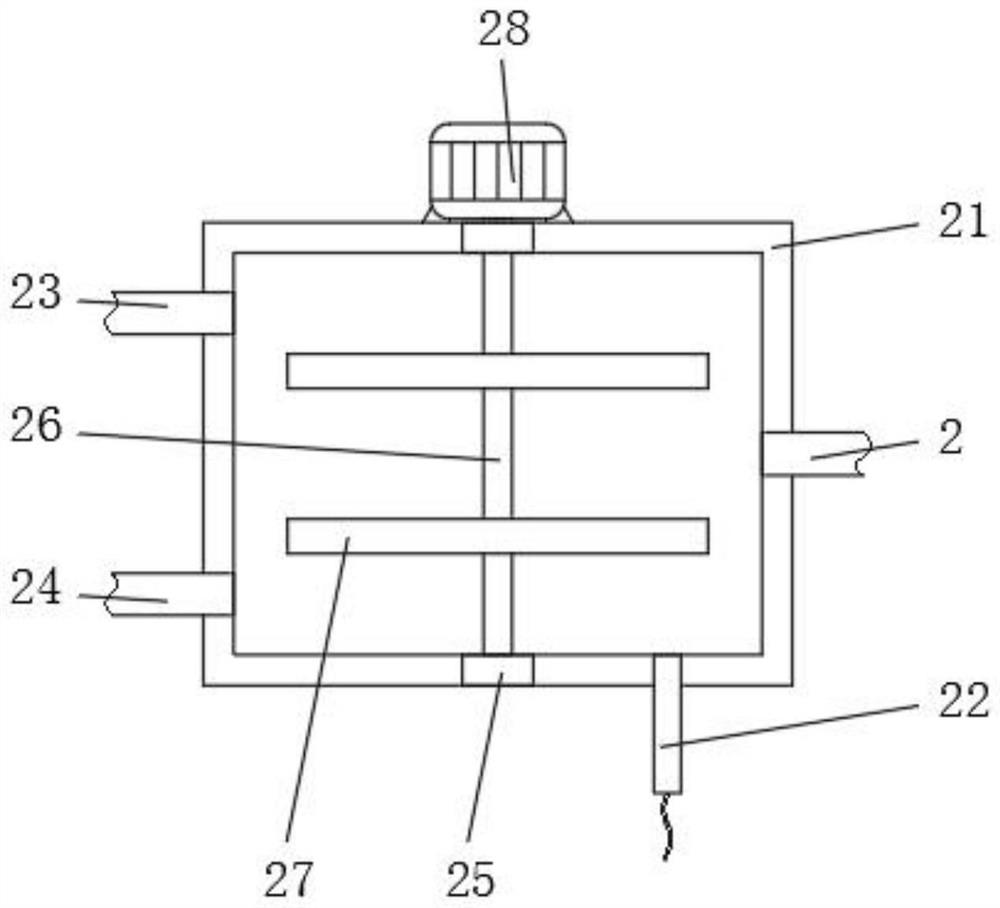

[0028] Embodiment 1: A rapid cooling device for intelligent temperature detection for injection molding, including a base 1, a water inlet pipe 2, an upper mold body 3, a second bearing 4, and a water tank body 21, and the outer wall of the upper end of the base 1 is provided with a lower The mold body 11, the upper outer wall side of the lower mold body 11 is provided with an upper mold body 3, the lower mold body 11 and the outer wall on the opposite side of the base 1 are provided with a cooling groove 12, and the lower end of the inner wall of the cooling groove 12 is plugged with a water inlet pipe 2. The upper mold body 3 and the outer wall of the lower mold body 11 on the opposite side are provided with mold grooves 33, and the mold grooves 33 achieve the purpose of injection molding workpieces;

[0029] A feed pipe 32 is inserted on one side of the outer wall of the upper end of the upper mold body 3, and the feed pipe 32 communicates with the inside of the mold cavity ...

Embodiment 2

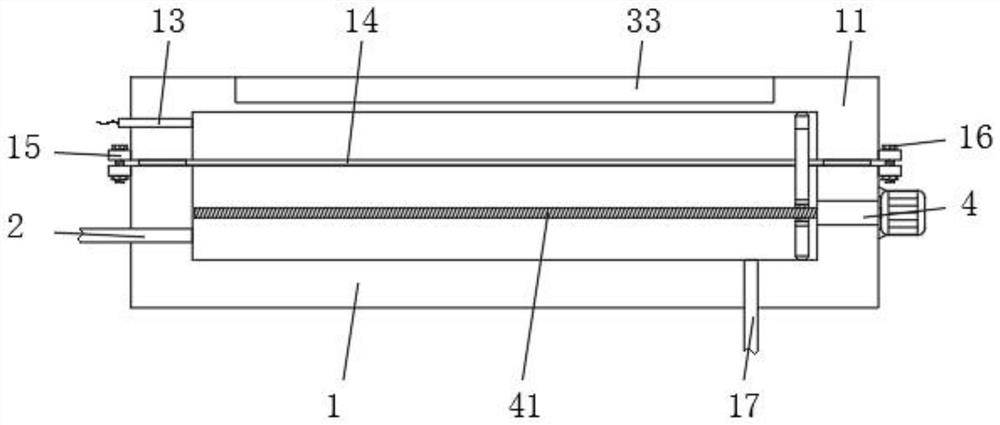

[0036] Embodiment 2: A rapid cooling device for intelligent temperature detection for injection molding, including a base 1, a water inlet pipe 2, an upper mold body 3, a second bearing 4, and a water tank body 21, and a bottom wall is provided on one side of the upper end of the base 1. The mold body 11, the upper outer wall side of the lower mold body 11 is provided with an upper mold body 3, the lower mold body 11 and the outer wall on the opposite side of the base 1 are provided with a cooling groove 12, and the lower end of the inner wall of the cooling groove 12 is plugged with a water inlet pipe 2. The outer wall of the lower end of the lower mold body 11 is attached and fixed with a gasket 14. The gasket 14 is located outside the cooling tank 12, and the gasket 14 is in contact with the outer wall of the upper end of the base 1. The gasket 14 is used to ensure that the base 1 and the lower mold The tightness between the main bodies 11 prevents the cooling liquid inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com