Rotary electromagnetic heat pump system

A heat pump system, electromagnetic technology, applied in the field of electromechanical, can solve the problem of low heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

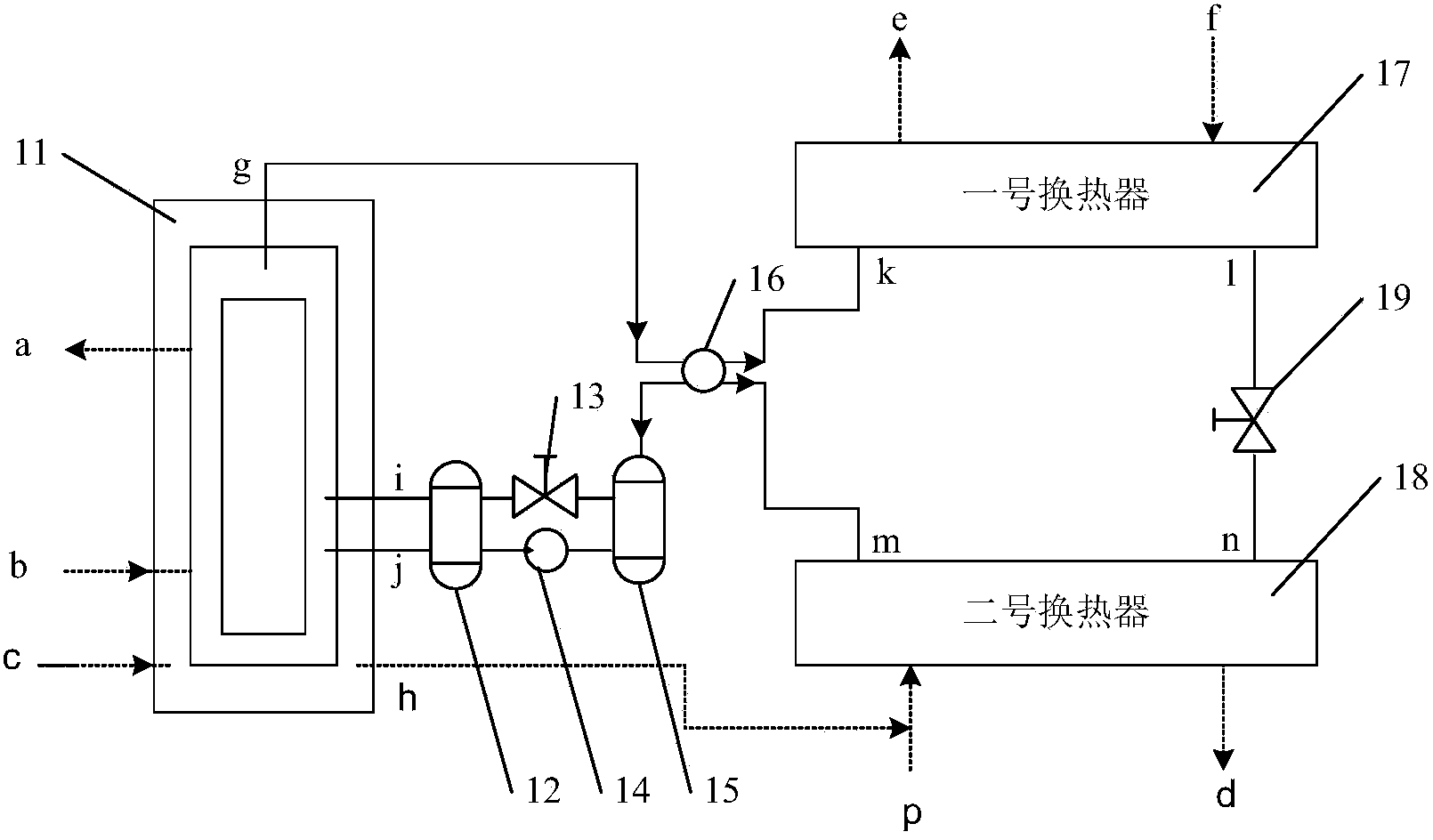

[0027] Specific implementation mode one: the following combination figure 1 Describe this embodiment, a rotary electromagnetic heat pump system described in this embodiment, which includes a rotary electromagnetic generator 11, a solution heat exchanger 12, a throttle valve 13, a solution pump 14, an absorber 15, and a four-way valve 16 , No. 1 heat exchanger 17, No. 2 heat exchanger 18 and No. 2 throttle valve 19;

[0028] The rotating electromagnetic generator 11 is provided with an external gas inlet a, an external gas outlet b, an external medium inlet c, an external medium outlet h, two working medium inlets and one working medium outlet;

[0029] The working fluid outlet g of the rotating electromagnetic generator 11 is connected to the No. 1 interface of the four-way valve 16;

[0030] The No. 1 heat exchanger 17 is provided with an external liquid medium outlet e, an external liquid medium inlet f, a working medium inlet and a working medium outlet;

[0031] The No. ...

specific Embodiment approach 2

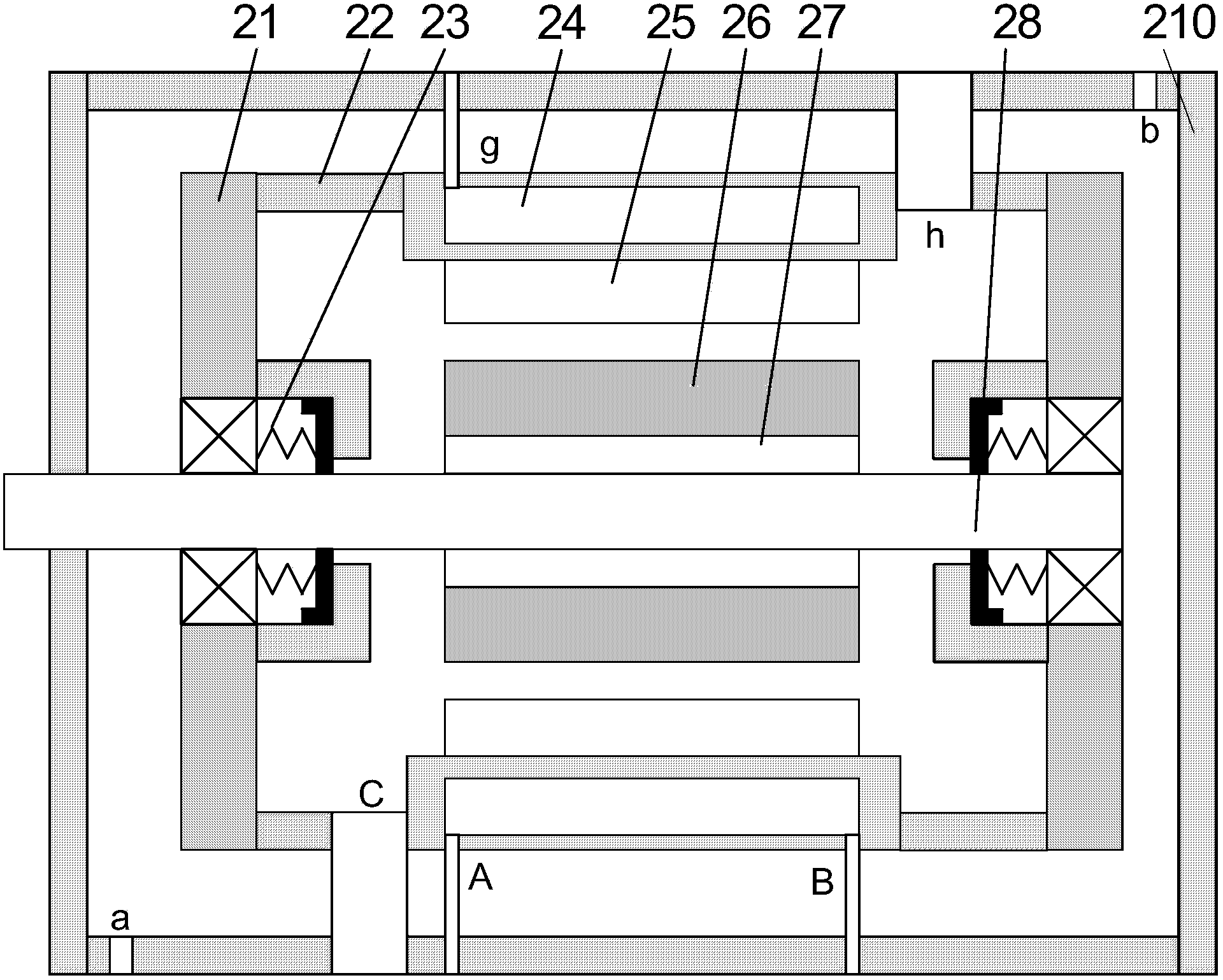

[0041] Specific implementation mode two: the following combination figure 1 , figure 2 and image 3 Describe this embodiment, this embodiment will further explain Embodiment 1, a rotary electromagnetic heat pump system described in this embodiment, the rotary electromagnetic generator 11 includes two end covers 21, a housing 22, a bearing and a sealing assembly 23. The stator, the rotor, the rotating shaft 28 and the heat preservation shell 210 are composed; the end cover 21 is a disc-shaped end cover, and the shell 22 is a cylindrical shell;

[0042] The two end covers 21 are installed at both ends of the casing 22 respectively, and the stator and the rotor are both arranged inside the casing 22;

[0043] The center of the end cover 21 is provided with a bearing seat; the bearing and sealing assembly 23 are fixedly installed in the bearing seat; the rotating shaft 28 is rotationally connected with the end cover 21 through the bearing and sealing assembly 23;

[0044] The ...

specific Embodiment approach 3

[0054] Specific implementation mode three: the following combination Figure 4 Describe this embodiment, this embodiment will further explain Embodiment 1, a rotary electromagnetic heat pump system described in this embodiment, the stator core 25 is that M rectangular grooves are opened in the axial direction on the side wall of the inner ring The ring structure; the M rectangular grooves are evenly distributed on the side wall of the inner ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com