Rapid air cooling chamber for isothermal normalizing

It is a technology of isothermal normalizing and air-cooling chamber, which is applied in the direction of processing discharged materials, furnaces, lighting and heating equipment, etc. It can solve problems such as uneven temperature of different workpieces, uneven temperature of the same workpiece, and affecting the product quality of workpieces, etc., to achieve The effect of simple structure, uniform cooling speed and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

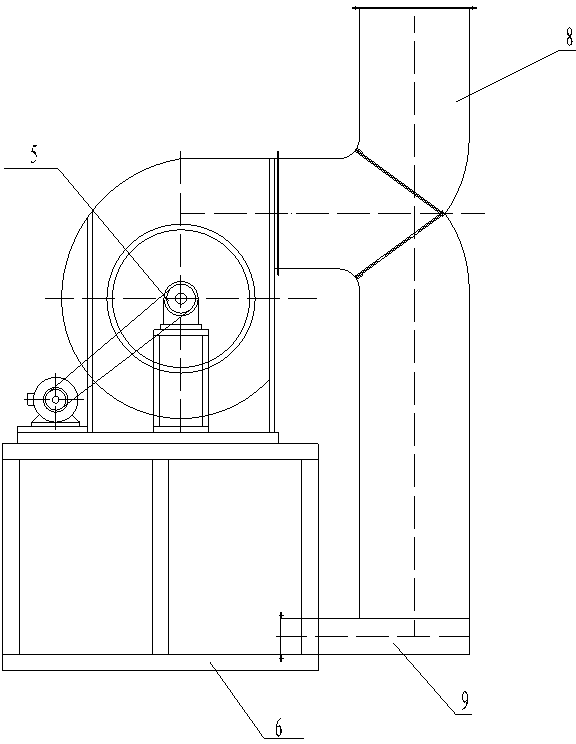

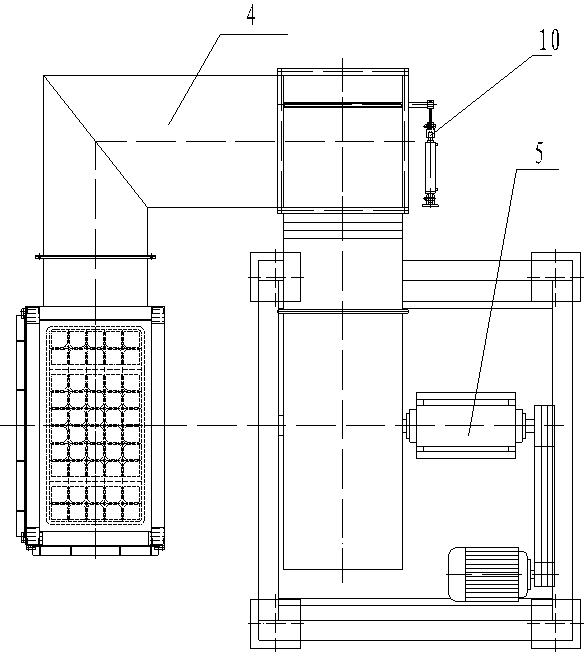

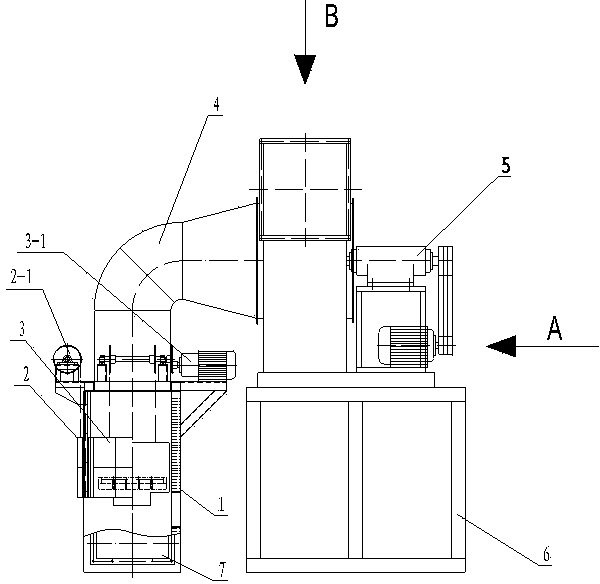

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] like figure 1 , figure 2 and image 3 The shown rapid air-cooled chamber for isothermal normalizing includes an air-cooled chamber body 1, a feed door 2 arranged on the left side of the air-cooled chamber body 1, and an outlet door arranged on the rear side of the air-cooled chamber body 1. Material door 3, feeding door lifting mechanism 2-1 for controlling the opening and closing of feeding door 2, discharging door lifting mechanism 3-1 for controlling the opening and closing of discharging door 3, centrifugal fan 5 and fan support frame 6 driven by a motor , the centrifugal fan 5 and the motor that drives the centrifugal fan 5 to rotate are all arranged on the fan support frame 6, and the fan support frame 6 is separated from the air-cooled chamber body 1 by a certain distance to prevent the vibration of the centrifugal fan 5 fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com