Standing wave tube installation mechanical device for sound intensity measurement instrument calibration device

A technology for calibrating devices and mechanical devices, applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc. It can solve the problems of difficult adjustment of installation holes, large spacing, and unfixed relative positions of standing wave tubes, etc., to improve repeatability , reduce workload, and reduce the effect of calibration error sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

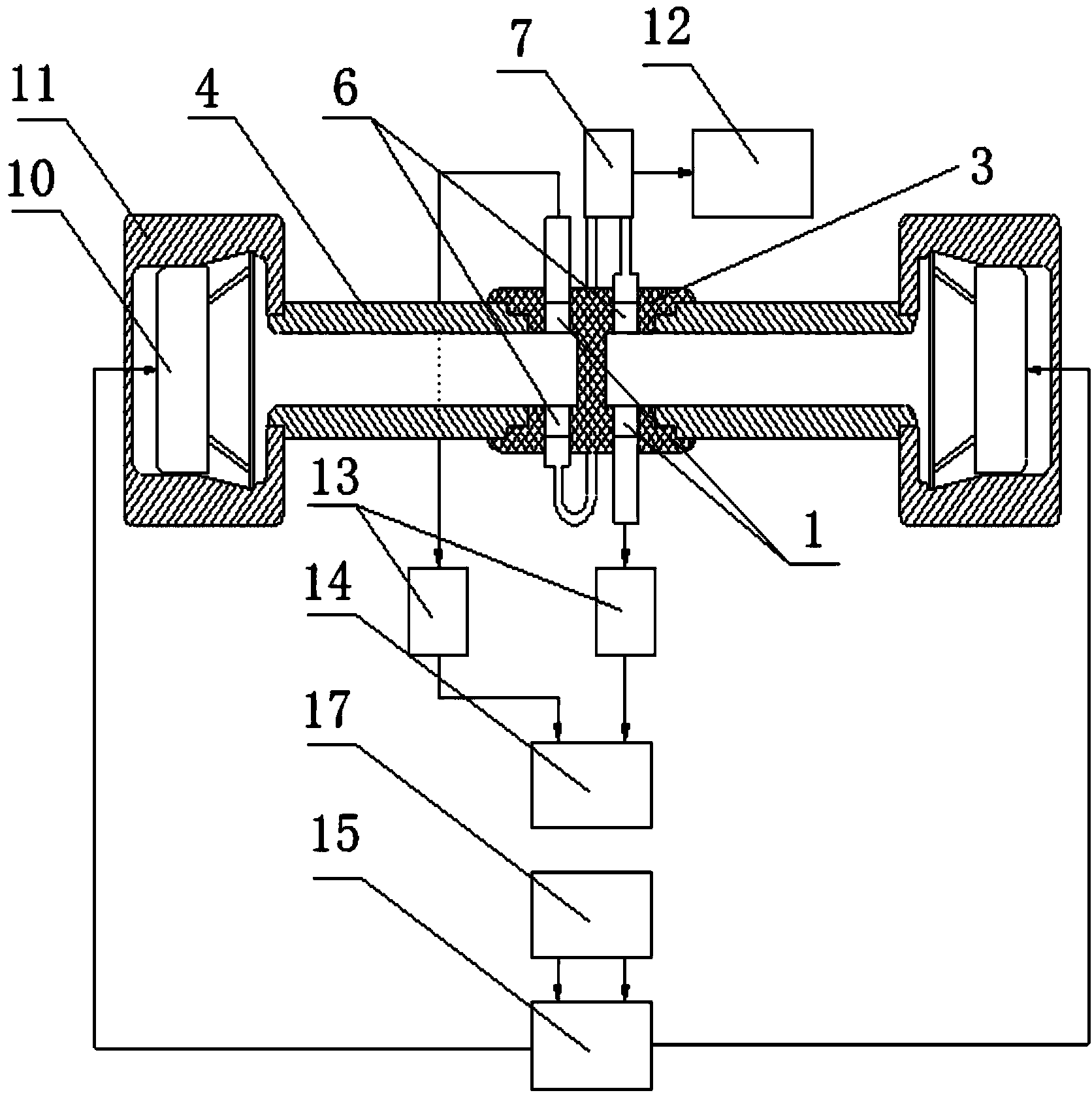

[0013] A standing wave tube installation mechanical device for a sound intensity measuring instrument calibration device according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

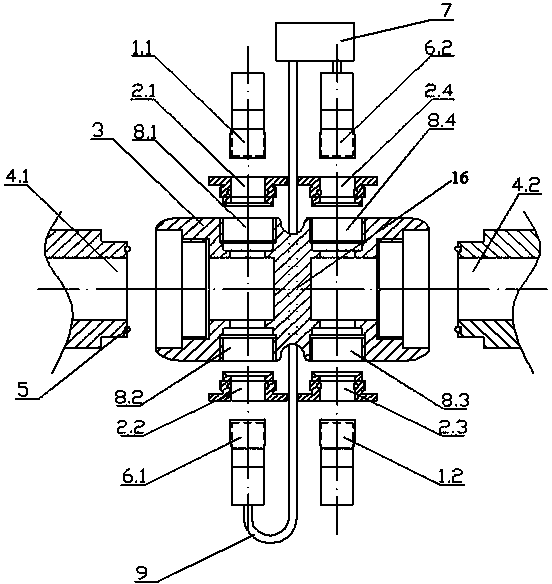

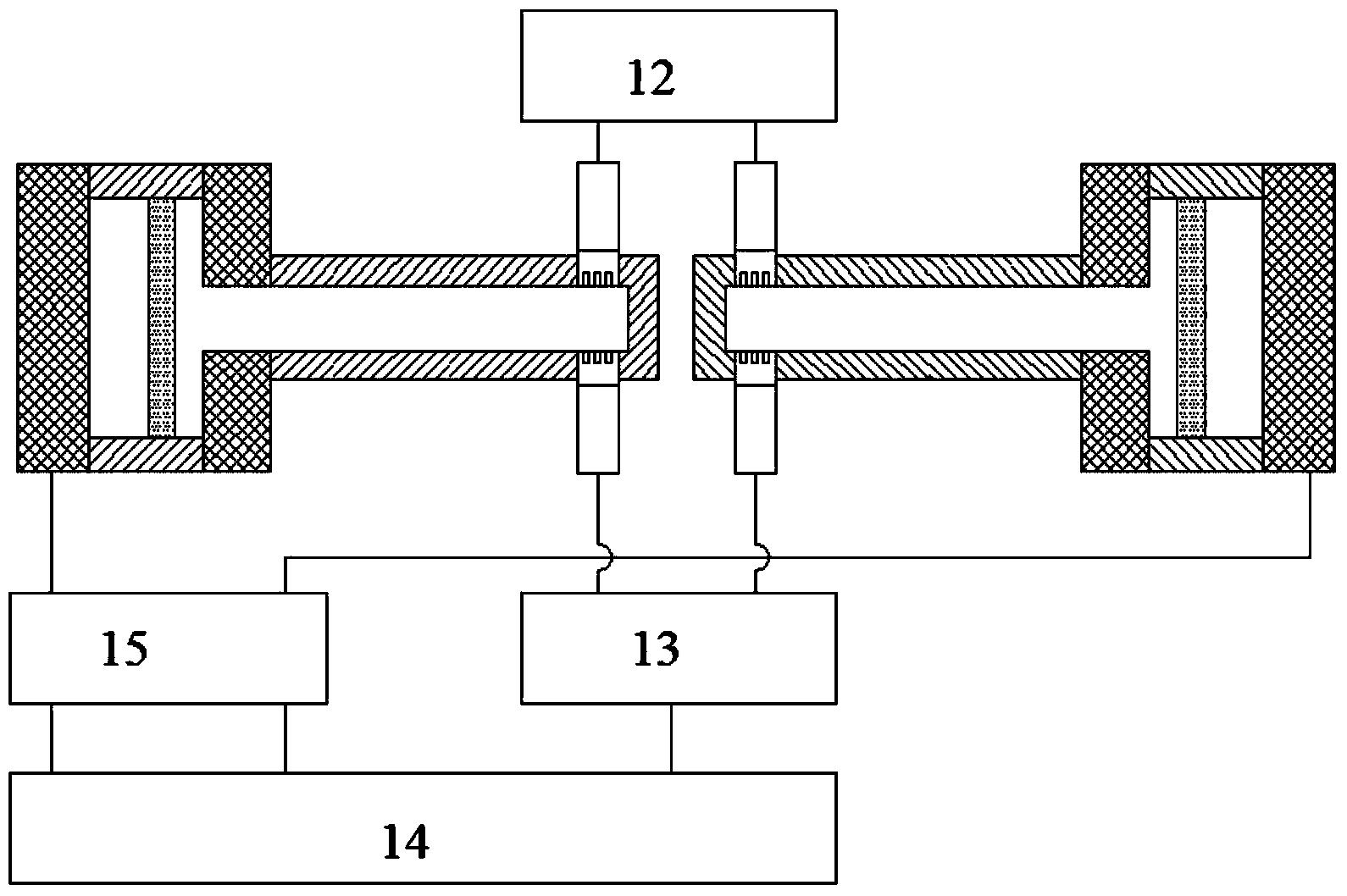

[0014] Such as figure 2 As shown, the ends of the two standing wave tubes 4.1 and 4.2 are designed as an integral structure in the calibrating device for the sound intensity measuring instrument according to the present invention. The outer diameter of standing wave tube 1 4.1 and standing wave tube 2 4.2 is 47mm, and the inner diameter is 25mm. The outer diameter of the connector 3 is 57 mm, the length is 105 mm, and the thickness of the connection interval 16 at the inner center of the connector 3 is 15 to 20 mm (for example, 15 mm, 17 mm or 20 mm); the center of the outer surface of the connection interval 16 has an annular concave groove.

[0015] Both sides of the connector 3 are threadedly connected to the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com