Pavement material hydrodynamic pressure scouring test machine

A technology of pavement materials and dynamic water pressure, which is applied in the direction of testing wear resistance, etc., can solve problems such as loud noise and poor working environment, and achieve the effects of improving stability, enhancing practical functions, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

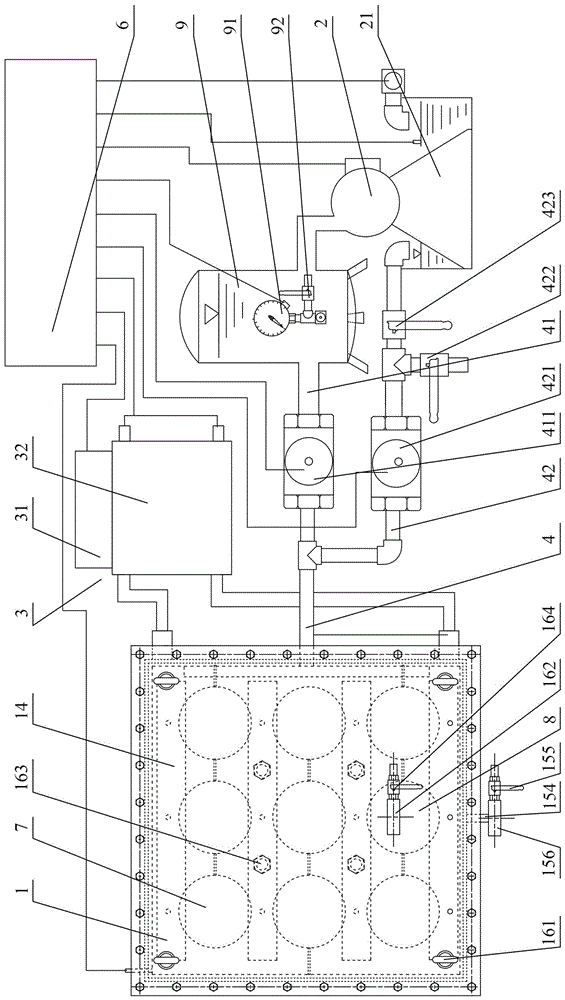

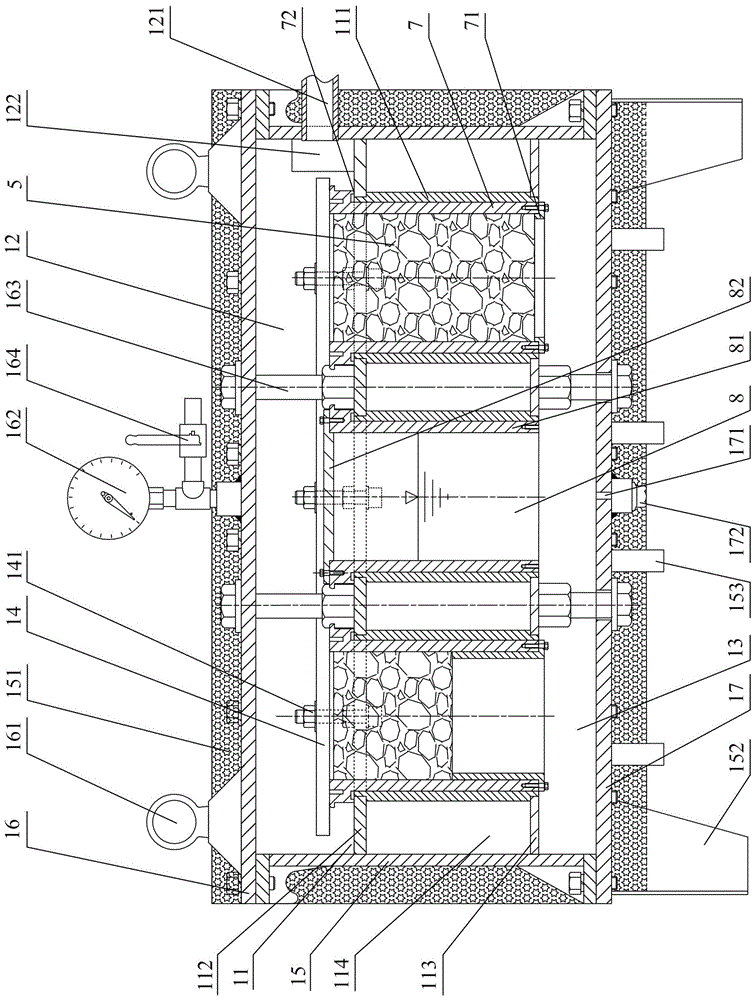

[0024] figure 1 and figure 2Shown is a kind of pavement material hydrodynamic pressure scouring test machine embodiment of the present invention, and this testing machine comprises airtight test chamber 1, water supply system and control system 6, and the airtight test chamber 1 is fixedly provided with mounting seat 11, and mounting seat 11 The inner cavity of the airtight test chamber 1 is divided into an upper forward flushing chamber 12 and a lower reverse flushing chamber 13. The forward flushing chamber 12 is provided with a dynamic water inlet and outlet 121 connected to the water supply system, and the mounting seat 11 is provided with multiple A positioning cylinder 111, the forward flushing chamber 12 and the reverse flushing chamber 13 communicate through the positioning cylinder 111, wherein at least one positioning cylinder 111 is provided with a reverse flushing cylinder 8, the upper end of the reverse flushing cylinder 8 is closed, and the lower end is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com